In today’s automated world, advances in machine complexity, speed and efficiency can result in hazardous risks to operators and equipment. Knowing that faster and more complicated systems are commonplace, it is critical to ensure that today’s machines provide the necessary safety features to protect human lives and equipment.

In the U.S. and other parts of the world, many, if not all industrial and commercial facilities are required to follow strict lockout/tagout procedures designed to protect the lives of workers and anyone with access to the area where the machine is located.

There are many things to take in consideration when deciding the safest way to protect human lives and machinery. Some examples of equipment that might be used for machine guarding and safety are:

- Guards that block access to all moving parts

- Safety switches that detect when a guard, gate, or door is open and disables power to the machine

- Shields that protect from flying debris

- Curtain lights/barriers that disable the machine if someone crosses their path

- Pushbuttons, sensors and devices that help disable a machine

All of these safety measures are efficient and reliable; however, there may be considerable wiring or a complex control system, which will result in additional costs and maintenance. In addition, there is always a risk of serious injury or death due to human error or miscommunication.

Accidents Can Happen

Accidents Can Happen

Let’s consider a case where a machine becomes jammed, or has a problem where a maintenance technician is required to resolve the issue. The technician first powers down the machine to safely work on it. During this time the operator may become distracted. If he does not see the technician, he may inadvertently energize the equipment. This creates a very dangerous situation for the technician, electrically and mechanically.

One possible way to prevent this is for a facility to mandate a lockout/tagout procedure that must be used any time a machine is being serviced. The OSHA website provides information on their minimum requirements for lockout/tagout procedures. Still, even following these required procedures, there is always a risk of human error due to poorly trained or untrained personnel. The picture on the right shows an example of a power switch locked using a lockout/tagout procedure.

Simple and Cost-Efficient Protection

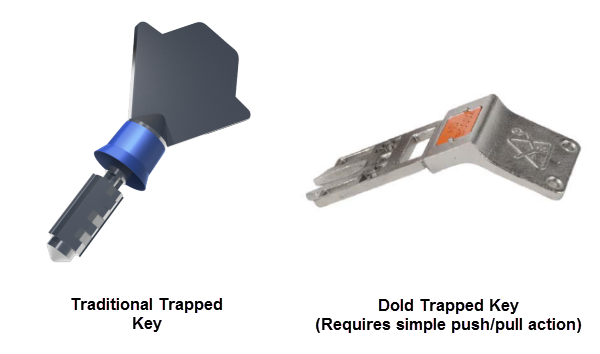

As an added measure of safety, a simple and cost-efficient way to improve a system and add an additional layer of protection is by using a “Trapped” key system. This is an electro-mechanical system that when properly designed and integrated will help to ensure safe access to a hazardous area using an exchange of keys. Keys can come in a few different styles (examples shown below).

Dold Trapped Key Systems

The Dold SAFEMASTER STS is a system that incorporates the functions of switches, guard locks and trapped keys into one single system. This provides enforced sequences for a safe working environment with minimal wiring and control complexity and reduced costs.

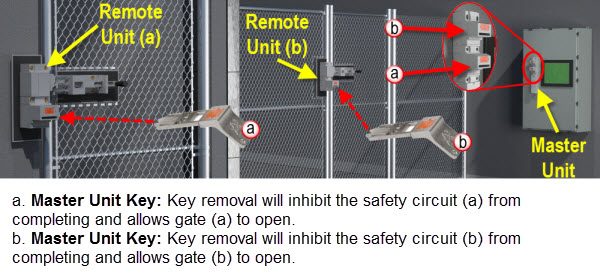

The Dold trapped key systems, available on the AutomationDirect website, use a series of mechanical locks and keys to control the access of gates or doors of running equipment or machines, ensuring safe access to them. The trapped key system allows removal of a key from a master segment ONLY when the machine control power is isolated. The removed key can then be used to open a mechanically locked door or gate. The door or gate cannot be opened until the key is properly installed. Once the door or gate is open, the key is trapped and cannot be removed until the respective door or gate is securely closed. Other personnel would know that only the person who opened the door or gate can close them.

In a properly designed system with the key trapped in the remote door, the master unit will ensure that the control cannot be energized unless the remote door is closed securely and the trapped key released. Once a worker completes the task, exits the secured area and closes the door or gate securely, they will be able to remove the key and place it in the master unit. Then the safety system is complete, allowing the operator to restart the machine. A lock system can be incorporated into the system to ensure that no one can tamper with the key. In addition, the Dold Trapped Key system has the ability to have a removable key at the remote door that the worker can take along, making sure that no one can use the key until the task is complete and the area is cleared. This system can also be used in multiple door or gate arrangements.

In a properly designed system with the key trapped in the remote door, the master unit will ensure that the control cannot be energized unless the remote door is closed securely and the trapped key released. Once a worker completes the task, exits the secured area and closes the door or gate securely, they will be able to remove the key and place it in the master unit. Then the safety system is complete, allowing the operator to restart the machine. A lock system can be incorporated into the system to ensure that no one can tamper with the key. In addition, the Dold Trapped Key system has the ability to have a removable key at the remote door that the worker can take along, making sure that no one can use the key until the task is complete and the area is cleared. This system can also be used in multiple door or gate arrangements.

Given all the advances in speed and efficiency in today’s technology, Dold Trapped Key systems are a smart and cost-effective solution for providing a safe environment for your most valuable assets, your employees and machinery. For more information on Dold Trapped Key systems, please see our videos Trapped Key System Overview and Trapped Key Helpful Hints, Tricks and Installation Tips. You may also find answers to some of your questions on our Dold Trapped Key Systems Faqs page.