Because the sugar mill operates in overdrive production for just four months out of the year, and recovers for the other eight months, reliable products are essential for maximizing uptime during the busy season.

By Josh Camel, M.A. Patout & Son Sugar Mill

At most manufacturing plants, the production year is near-constant, with occasionally scheduled times for preventive maintenance and other shutdown operations. During these rare periods, a team of engineers, technicians, and operators—temporarily converted into maintenance personnel—race to prepare the factory to run like new mere days later.

For sugar cane processor M.A. Patout & Son, the production/maintenance cycle is turned on its head because the annual harvest occurs over a few short months, demanding an intensive effort to process a massive amount of sugar cane before it spoils.

Once the harvest starts, processing it is all-hands-on-deck for four months of intense production, with engineers and technicians making sure the plant operates as expected—or at least holding things together as best they can—until the work is done. The plant is then shut down until the next run eight months later. During this time, plant personnel rebuild equipment and make improvements. One might compare this process to how a professional sports team performs on game day, but puts in a massive amount of work throughout the year to prepare.

To ensure peak performance during the production sprint, and to enable useful upgrades during the maintenance period, the company needs reliable and readily available automation components.

A Sugar-Processing Sprint

The unique challenge for sugar cane processors—including M.A. Patout & Son, which has been in the Louisiana sugar industry since 1825—is that during the four months of processing, the plant must run (Figure 1). If something breaks, quick access to replacement parts, support, and documentation is absolutely critical.

Downtime is bad in any industry, but the time-sensitive nature of processing sugar cane means that interruptions simply cannot be made up with extra working hours or by pushing back the delivery date. Furthermore, because the overall process demands significant effort to properly startup and shutdown, any unscheduled outages can have an oversized effect on downtime.

Component reliability is important for any application, and a sugar mill tests equipment and components in an extremely harsh environment with extremes of temperature, vibration, debris, and more. In most cases, it is not a matter of if a part will fail, but when. Some components are considered sacrificial to an extent, and will only last one season.

With a long history of learning what approaches result in reliable production, M.A. Patout & Son effectively rebuilds their entire processing operation every year—to the point where it nearly becomes a new facility. This renovation includes servicing everything from mechanical equipment to electrical and control systems, and provides the opportunity to improve the process engineering where it makes sense. Almost all of this work is performed in-house, including servicing control panels, running conduit, and rebuilding valves.

Since many of the operators need a job in the eight-month offseason, it is a natural transition for them to perform many of the maintenance operations. As an added benefit, when the plant is running, they know how to fix or replace everything in the facility. Even though new parts are typically specified and installed in the comparatively calm offseason, the mindset of plant engineers has to be that replacement parts must be available at a moment’s notice. Lead time and supplier reliability are therefore paramount to the operation, and when it is cost-effective they strive to keep critical component spares on-hand for instant access.

Reliability and Availability Keep the Plant Running

The primary boiler automation system consists of specialized legacy controllers that have proved reliable. However, for many other subsystems, the site takes advantage of AutomationDirect’s extensive product offerings.

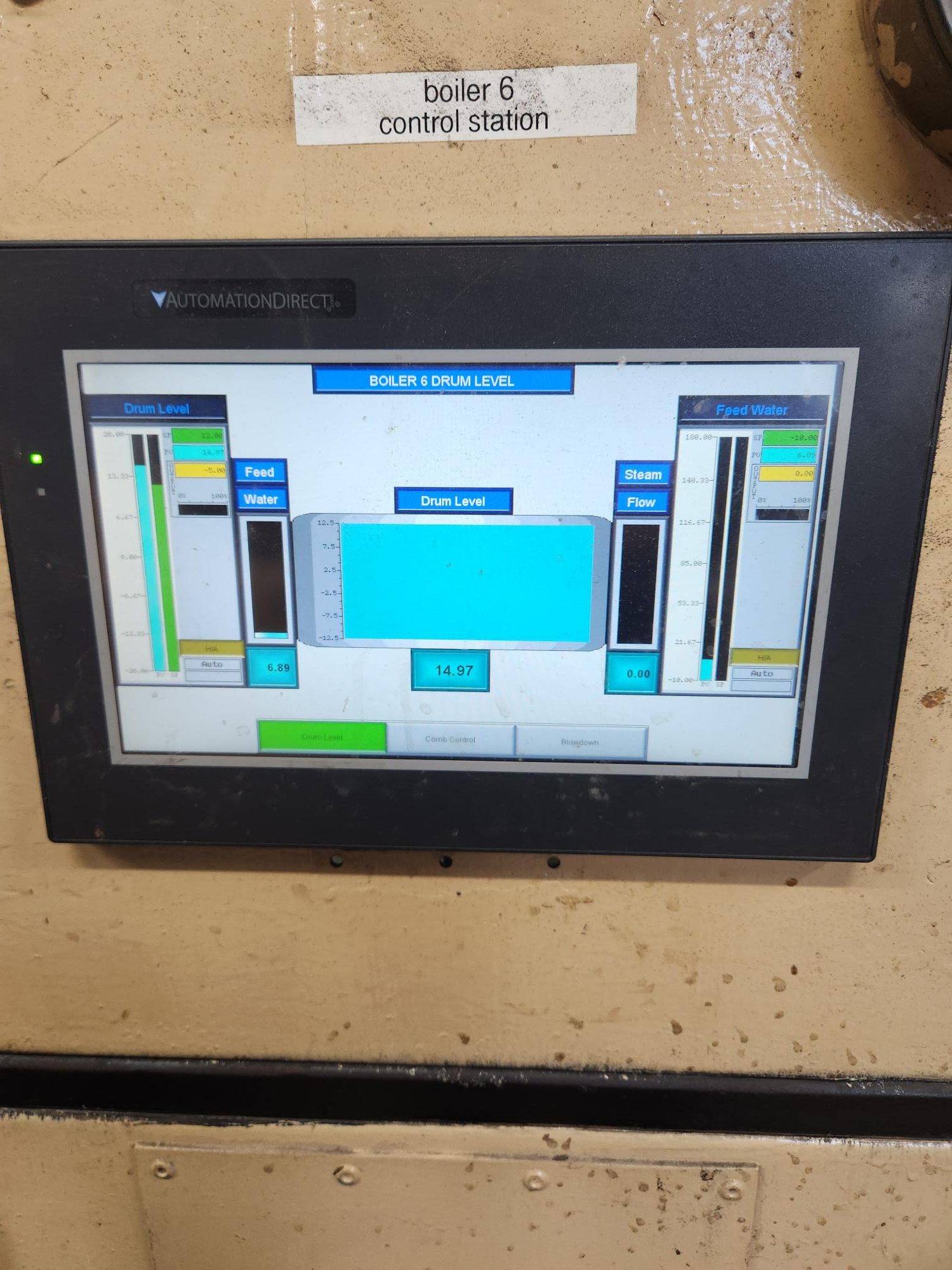

Productivity and CLICK programmable logic controller (PLC) lines are implemented to handle a wide range of automation duties. For human-machine interface (HMI) tasks, C-more graphical touchscreen HMIs are localized near individual equipment to provide easily-deployed operator access (Figure 2). Once the new hardware is in-house, AutomationDirect’s free programming software makes it easy to quickly set up the panels. This free software paradigm extends to their PLCs, drives, field IO, and more. The site also has also had plenty of positive experience using ProSense pressure, temperature, and vibration sensors and transmitters from AutomationDirect, as they provide plenty of accuracy and have proven durable in service.

Installing these HMIs right where they are needed near equipment is beneficial for the operators, but this also subjects the devices to a massive amount of heat, humidity, and liquid contamination. The technical staff considers HMIs in these conditions as sacrificial, regardless of the brand or quality. When panel replacements need to be ordered, AutomationDirect’s online inventory display system ensures that a new device will be procured on time. Or, if a substitute needs to be considered, AutomationDirect’s online documentation and personal phone support are there to help.

Boiler Feed Pump Project

When the plant goes down each year for service, engineers do not just replace and rebuild existing components, but they also take this opportunity to implement new ideas.

Currently, after sugar juice is extracted, the remaining fibrous pulp, known as bagasse, is burned in seven biomass boilers. This generates steam that is in turn used to operate turbine pumps supplying boiler feed water at up to 1.2 million pounds of water per hour. While this biomass-based system effectively burns waste and makes the plant largely self-sufficient from an energy standpoint, there are several downsides. Biomass tends to have a widely varying energy content depending on moisture. Steam systems are challenging to startup/shutdown and keep in good operating balance, and they are notoriously high maintenance. The seasonal usage pattern—fully loaded for a few months, idle for the rest of the year—also negatively impacts the lifespans and performance of the steam-based equipment.

To improve flexibility, performance, and overall efficiency, the site is exploring the move to cogeneration (often shortened as “cogen’) to produce electricity in an environmentally friendly manner in the future. Steam would still be produced, but it would be used to make electricity to power site equipment (rather than spinning turbines that mechanically operate equipment). As a first step in this direction, it was decided to add a new 250-horsepower variable frequency drive (VFD) controlled boiler feed pump to operate in parallel with the existing steam-driven units (Figure 3).

The facility has already successfully used AutomationDirect variable frequency drives (VFDs) in a variety of smaller applications. The fact that many of the smaller VFD versions are washdown-capable is very convenient for this environment.

While some other brands have been used before, in recent years the team has found AutomationDirect to provide much better—and more reliable—delivery lead times, which has become an important factor. High product quality, solid technical performance, and pricing are important attributes, but in the rigorous world of sugar processing, other considerations such as short lead times, supplier reliability, and great support play key roles when specifying automation components.

With all this in mind, the team is confident that the new VFD-driven pump will work well as a next step in improving process performance. Of course, the facility will always require some steam-driven pumps in operation, as they produce low-pressure steam used for heating. But once a degree of cogeneration is available, the site will have options for balancing the overall electrical load in relation to what the utility can supply, especially when production overlaps with hot Louisiana summer months where air conditioning loads are a considerable demand.

Sweetening the Sugar Cane Production System

Faced with relentless environmental challenges and unforgiving production schedules, designers and engineers in the sugar cane industry must rise to the occasion with ingenuity and resilience. Each approaching harvest season brings a whirlwind of activity—systems rebuilt, processes refined, and improvements forged under pressure. Partnering with reliable suppliers for PLCs, HMIs, electrical equipment, and other automation products empowers end users, integrators, and original equipment manufacturers to keep the gears of production turning. In this demanding landscape, only those who adapt and innovate truly thrive.

All figures courtesy of M.A. Patout & Son