A home project to upgrade a garage door system with an AutomationDirect PLC, HMI, and VFD made the equipment run better, added many functional features, and provided extensive visibility and diagnostics.

Industrial automation components have many applications outside the factory. Home and hobbyist projects can be a great way for learning how to execute larger projects, while providing very useful results.

In a February 2022 Control Design article bylined by retired engineer Mike Thiel, titled Automation Skills Offer a Lift at Home, he describes how he upgraded a problematic shop rollup door with new features and improved functionality.

Surpassing Stock

Thiel’s 60×100 foot garage houses recreational vehicles, a tractor, and even a dump truck. A 16×14 foot rollup door with a commercial-grade electric opener provides access.

However, this standard 120VAC 0.5HP device simply provided “bang-bang” control, either violently opening or closing the door to the limit at full speed when operated. This stretched the mechanism chains, and added wear and tear on the door, to the point where it would fail to operate properly at times.

There were no diagnostics available in the event of trouble. More problematic was the fact that many times it was desirable to open the door only part way, for a lower vehicle or to provide air flow. To address these and other issues, Thiel decided to apply his industrial automation experience to develop a commercial off-the-shelf (COTS) solution.

Superior Solution

With former good experiences using AutomationDirect PLCs, HMIs, VFDs, and other automation components, Thiel knew where to look to get what he needed, while remaining within budget.

- CLICK Series stackable micro-brick PLC: Plenty of logic capability, lots of I/O options, communication ports, and free programming software.

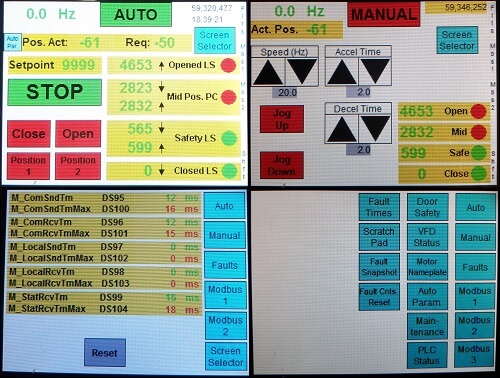

- C-more Micro touch panel: Six-inch color touchscreen with five user-definable buttons, and free programming software.

- GS2 Series AC Drive: Able to accept 120/240V 1P/3P input power and generate 240V 3P output, with communications.

- IronHorse 0.5HP 3P motor: Inverter rated, and suitable for pre-mounting on the door opener.

- Various sensors and wiring accessories, such as ZIPLink pre-wired connection cables, along with other items.

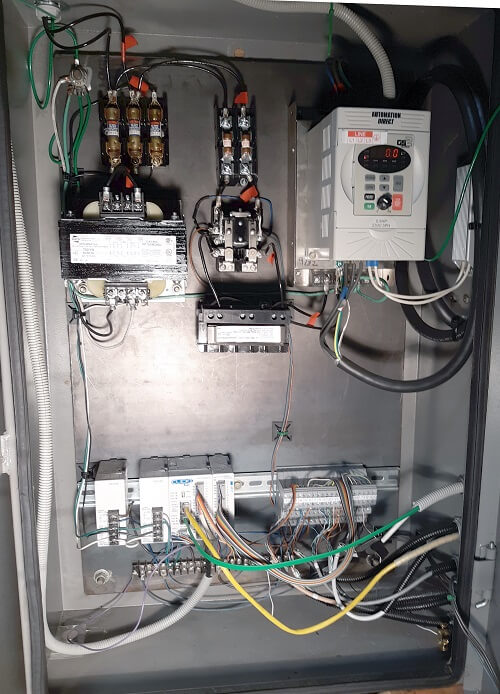

He installed these components into a compact yet easily serviceable control panel, and made sure to create a system architecture drawing defining all the connections and settings. The project uses classic PLC wired I/O, and serial communications between the PLC and VFD.

Programming Passage

The door keeps traditional limit switches, but Thiel added a proximity switch and a sprocket to act as a durable encoder, enabling the PLC to track door travel distance with a repeatability better than ±0.25 inch. The HMI displays door status, control buttons, user settings, and detailed I/O and communications diagnostics. He created advanced operations like:

- Automatic, manual, and jog modes

- Normal close

- Open to various heights

- Smooth acceleration and deceleration

Make it Your Way

This project applied COTS technology to meet everyday needs, and it provides an example of how larger projects can be executed. According to Thiel:

“Consumer goods are often quite advanced today as manufacturers strive to meet consumer needs. But there are still cases, such as the standard garage door opener, where the results fall short. For this situation, I was able to use components to create a control system that operated the equipment more efficiently and economically with less wear, while adding many functional and diagnostic capabilities.”

Check out the AutomationDirect.com website today to explore products that can help your company control its own automation destiny.

All figures courtesy of Mike Thiel