Point-to-point wireless I/O technologies provide a helpful solution for efficient low-I/O-count remote connectivity.

While some industrial monitoring and control systems are easily connected to their associated field devices, the harsh reality is that many installations are much more complicated. Input/output (I/O) signaling over long distances, especially where there is not a convenient wiring path, is a costly proposition. An Industrial Equipment News November/December 2025 article by AutomationDirect’s Rin Irvin, titled Wireless I/O Gets to the Point, describes a point-to-point wireless I/O solution, providing a real problem solver for many applications.

Making the Connection

For monitoring and control systems, I/O signals are the “nervous system” which connects the digital controller “brain” with the field-located instrument “senses” and actuator device “muscles.” Traditional hardwired methods, and now digital communication protocols over media like Ethernet and other fieldbuses, have long served the connectivity role.

However, when I/O points are distributed over long distances—especially where there really is not a practical conduit path— traditional wiring is impractical at best, and it can be downright cost-prohibitive as a permanent solution. And for temporary solutions, such as adding a clamp on flowmeter or electrical current monitoring during commissioning, it just doesn’t make sense to install costly field wiring.

Advantages of Point-to-Point Wireless

There are some large-scale wireless technology platforms capable of providing wide-range connectivity throughout an entire site. But for many users, and better solution is the use of dedicated point-to-point wireless I/O devices as a fit-for-purpose way to establish convenient connectivity over useful distances for a handful of essential I/O points.

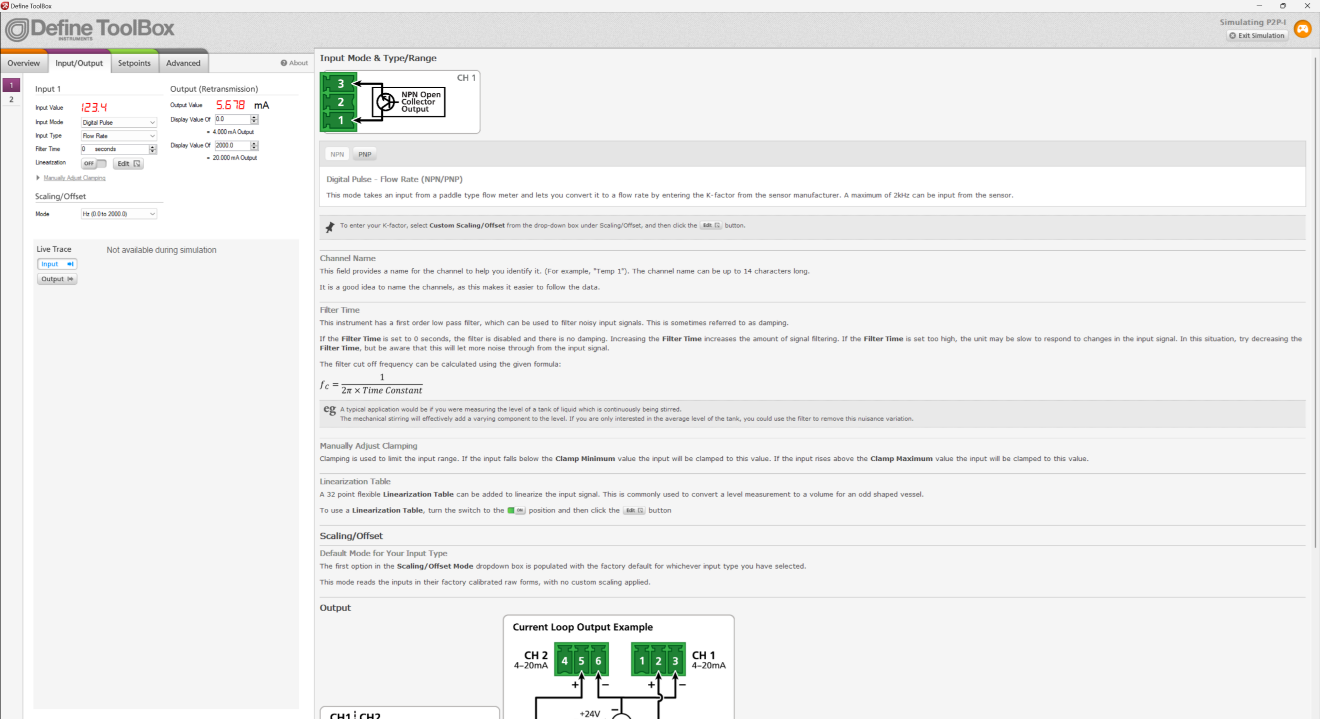

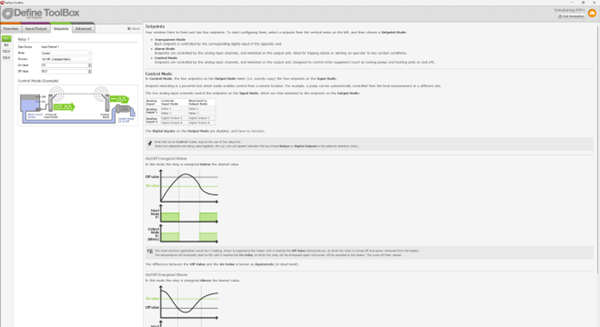

To meet this need, AutomationDirect offers the Define Instruments Twin Link wireless point-to-point system, which provides exceptionally flexible signal handling and simple configuration to meet the needs of even the smallest I/O installations. These applications commonly need just one or two analog signals, along with a few discrete on/off points. Key characteristics of this product line include:

- Compact form factors designed to withstand harsh conditions.

- Input nodes accepting two universal isolated inputs (milliamp, voltage, thermocouple, RTD, potentiometer, and digital pulse).

- Output nodes delivering two 4-20mA analog outputs.

- Both input and output nodes feature discrete I/O in the form of four digital inputs, two digital outputs, and two relay outputs.

- Transmission range up to 0.9 miles line-of-sight between input and output nodes, with the ability to add up to 15 repeaters in between for even greater range, all operating at 2.4Ghz.

- Straightforward software configuration, with nearly plug-and-play simplicity using drop-down menus and sidebar help.

- The ability to scale signals, transparently pass-through signals, handle pulse trains, generate alarms, and provide basic control strategies such as pump control.

Modern digital controls and networking are enabling many forms of advanced industrial automation. However, there remain plenty of situations where targeted problem-solving solutions, such as wireless point-to-point devices, are the best way to create sophisticated solutions, while avoiding problematic installations.

About the Author

Rin Irvin is a Product Engineer at AutomationDirect. His career includes extensive experience in the water/wastewater industry, specializing in instrumentation and process controls as both a systems integrator and an end user. Rin has worked at AutomationDirect since 2022. He holds a bachelor’s degree in Criminal Justice, and is an ISA Certified Controls System Technician Level 3.