In many applications, single loop temperature controllers are sufficient to provide control of heating and cooling. But in some applications, including the one detailed in this article, closely coordinated control among many temperature control loops is needed. In those cases and others, PLC-based temperature control can be the best solution.

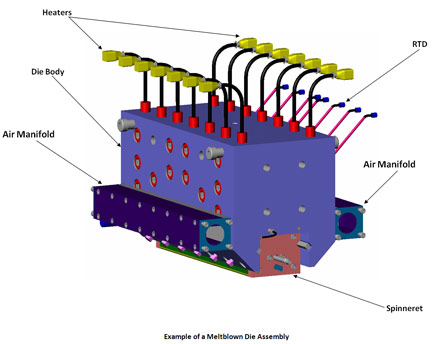

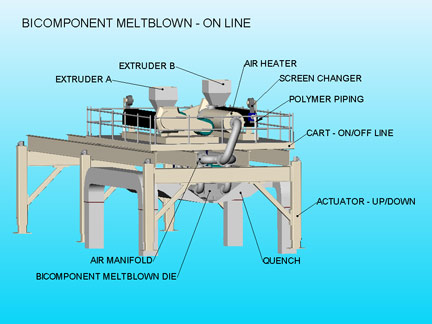

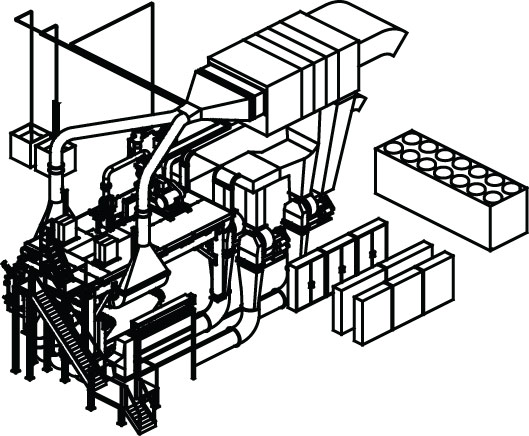

A meltblown machine, a melted polymer extrusion machine used in manufacturing nonwoven materials, consists of four main components. An extrusion system provides a steady supply of molten polymer, and a heated spinbeam distributes the polymer into an even sheet or web. A heated process air system is used to attenuate or stretch the fibers, and a vacuum system removes the process air as the nonwoven web is formed.

A meltblown machine, a melted polymer extrusion machine used in manufacturing nonwoven materials, consists of four main components. An extrusion system provides a steady supply of molten polymer, and a heated spinbeam distributes the polymer into an even sheet or web. A heated process air system is used to attenuate or stretch the fibers, and a vacuum system removes the process air as the nonwoven web is formed.

In many applications, single loop temperature controllers are sufficient to provide control of heating and cooling. But in some applications, including the one detailed in this article, closely coordinated control among many temperature control loops is needed. In those cases and others, PLC-based temperature control can be the best solution.

A meltblown machine, a melted polymer extrusion machine used in manufacturing nonwoven materials, consists of four main components. An extrusion system provides a steady supply of molten polymer, and a heated spinbeam distributes the polymer into an even sheet or web. A heated process air system is used to attenuate or stretch the fibers, and a vacuum system removes the process air as the nonwoven web is formed.

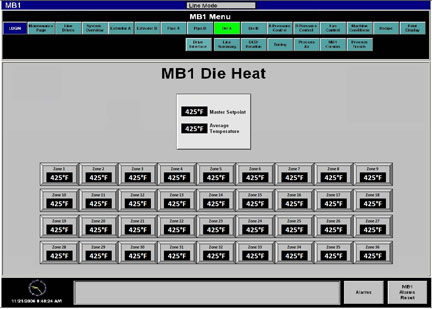

On this machine, each of the 36 zones had a PT100 RTD temperature sensor for feedback to that zone’s single loop temperature controller. An output from each controller switched a pair of cartridge heaters to maintain an average block temperature around 425°F. Biasing setpoints for each of the 36 individual zone temperature controllers could be entered by the operators of the machine to adjust the temperature profile across the length of the spinbeam.

Process air heated by a 320 kW electric circulation heater is delivered by a low pressure blower through large air manifold assemblies. These assemblies are constructed of 0.75″ thick 304 stainless steel plate attached to the die body using 28 12mm grade-8 bolts.

Varying Rates of Thermal Expansion

Thermal expansion of metal as it is heated is normally not a problem if all assembled parts expand at the same rate, or if clearances with tolerances down to the thousandths of an inch aren’t required. But in this case, there were significantly different rates of thermal expansion for the die body and the air manifold. This was causing these two components to separate to the extent that the bolts connecting the assemblies were shearing.

When the meltblown machine was started, the solid die body was heated with the cartridge heaters at a rate of 2° per minute. The air manifold assemblies were heated only by the pre-heated process air, and were thus increasing in temperature at a rate of about 1° per minute. With the two different heating rates, it didn’t take long to develop a significant temperature differential between the die body and the air manifold assemblies.

Because the solid stainless steel die body was more efficient at conducting heat than the hollow air manifolds, it could expand in length by as much as 1% (or 1.4 inches) before the air manifolds could expand. Something had to give, and in this case it was often one or more of the 28 bolts attaching the air manifold assemblies to the sides of the spinbeam.

The workaround solution was continuous intervention from the machine operators to monitor the die body and air manifold temperatures, and to adjust the temperature setpoints on the 36 individual controllers as required. A better solution was needed, one that replaced constant operator attention with automated control.

The Power of the PLC

After analysis and process trials, it was determined that the system could handle a maximum temperature differential of about 50°F between the die body and the air manifolds without shearing the bolts. One possible solution to maintain a maximum temperature differential was to install heaters and additional controls on the air manifold assemblies. However, due to their complex shape and space limitations, this solution was cost prohibitive. A better solution was an improved automation system in the form of a PLC and a Human Machine Interface (HMI). Historically, PLCs were used for discrete control applications, but today’s powerful PLCs have greatly expanded capabilities, particularly in the area of analog monitoring and closed loop control. These capabilities are provided in compact and low cost controllers featuring ease-of-use and a high degree of connectivity. On the meltblown machine, the individual single loop controllers were eliminated and the 36 RTD zone temperature sensors were wired to individual analog inputs at the PLC. Also, temperature sensors were added to monitor the incoming temperature of the pre-heated process air entering the air manifolds. Using the PLC’s internal math functions, the 36 die body zone temperatures are averaged and compared to the incoming air temperature in the air manifolds. Based on the measured temperature differential, the PLC automatically ramps the setpoints of the die body zones to individually control each zone’s pair of cartridge heaters. Specifically, the PLC determines the correct setpoint for each of 36 PID control loops. Each loop reads an RTD input as the process variable, and uses the internally derived setpoint to modulate a control variable analog output to control the heaters.

This PLC-based control solution allows the machine to automatically heat at a rate that is compatible with the thermal expansion of the different components. The bolt shearing problem was solved, and the need for constant operator intervention was eliminated.

In addition, pre-programmed biased setpoint temperature profiles in the PLC can now be automatically used as required, eliminating the need for machine operators to enter separate biasing setpoints in the individual single loop controllers.

In addition to the improved control functionality, the PLC continuously provides and trends valuable data to the HMI, such as the process variable, the setpoint including any biasing, and the loop output control variable. Alarm points and conditions, either globally or for each loop, can also be viewed at the HMI. Touch screen HMI inputs allow changes depending on different conditions such as the polymer type.

Prior to the use of PLC-based control, constant operator intervention was required to provide safeguards against damage and to manually track various process conditions. By introducing PLC-based control, possible machine damage due to varying rates of thermal expansion has been eliminated, and valuable insight provided by tracking and trending data that wasn’t readily available from the single loop controllers.

For complex temperature control applications with different heating or cooling profiles, PLC-based control offers a versatile, powerful and cost-effective solution. When paired with a touch screen HMI, additional process data can be viewed and analyzed, with adjustments to improve operations easily entered through the touch screen.

By Tim Hanes,

AutomationDirect

Process Instrumentation Equipment

Product Engineer

Originally Posted: June 1, 2011