The industrial pneumatics market is fairly mature. While there continues to be new developments and technologies, many of the tried and true core products have been around for years. One advantage that this can offer to both system designers and end users is often having several brands of pneumatic components that are interchangeable with each other. This can allow users the opportunity to shop around and look at more than one supplier for the same component.

The main reasons to use pneumatics are lower upfront and maintenance costs, which combine to make compressed air the most popular and cost-effective choice for executing mechanical motion. While there are some, especially electric actuator vendors, who claim electric motion is better due to its superior energy efficiency, it’s hard to beat the simplicity and reliability of pneumatics.

Pneumatic Components Cross Reference Guide

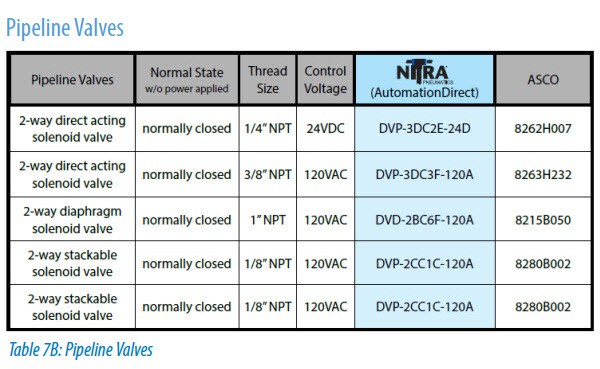

Competition is almost always beneficial to customers because now factors such as price, availability and service can be considered along with performance when making a buying decision. Check out our Interactive Cross Reference Chart here for a list of vendor components that are comparable to our NITRA Pneumatics line.

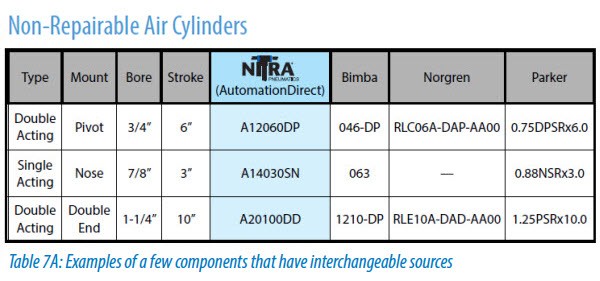

Here are examples of a few components that have interchangeable sources:

Care must be taken when changing brands to verify any possible differences in performance or dimensions. If you can adapt to some small differences, however, you may often be able to find a less expensive or more readily available component to do the same job as your current one.

Compact Extruded Body Cylinders:

100mm bore, 100mm stroke, magnetic piston

AutomationDirect: H100M100MD-M

Fabco-Air: GND-SA100X100DB

MFD Pneumatics: MACQ-100X100-S-T

Numatics: UND-SA100-100D-B

Parker: S100DC7G0100

SMC: CDQ2A100TN-100DZ

Originally published: March 21, 2016