Designers working on smaller automation systems can now take advantage of advanced yet economical motion control by using micro-PLCs and stepper motors.

Conor Perry, Technical Product Manager for the HMI and CLICK product groups at AutomationDirect, wrote an article for the October 2022 issue of Applied Automation. Titled Micro-PLC Motion Control Made Practical, the article explains how the AutomationDirect CLICK PLUS micro-PLC now includes powerful but accessible motion control functionality.

Motion control of electric motors has been possible for many decades, but typically has required integration of individual devices, making the technology expensive and complex, and only applicable for the most demanding applications.

Two recent developments have changed the situation, making PLC-controlled motion easy and cost-effective, suitable for industrial, commercial, and hobbyist applications. The first innovation is a micro-PLC with motion-specific instructions, and the second is the open-loop stepper motor (some with integrated drives) providing sufficient power, speed, and accuracy for most applications.

Motor Motion Options

Standard AC motors with VFDs, or DC motors with drives, can be used for on/off motion, relatively continuous service at fixed or varying speeds, and sometimes soft starting. But high-performance positioning, variable velocity/acceleration profiles, and intermittent motion usually calls for more expensive closed-loop servo motors and drives.

Stepper motors, available in standard DC and high bus voltage (AC) versions, are an option combining many desirable aspects of other motor types. Stepper motors can make small discrete motions—generally open-loop—following pulse commands, and they are popular for applications such as 3D printers, and machinery like lathes and CNCs.

Micro-Controllers

Each motor technology requires some type of motion controller, either built-in or external, to coordinate its functionality. Many larger PLCs include motion control capability, so users can more easily integrate motion with other equipment automation functions. But smaller applications with low I/O counts and three or fewer axes of motion would not be cost-effective using a large PLC.

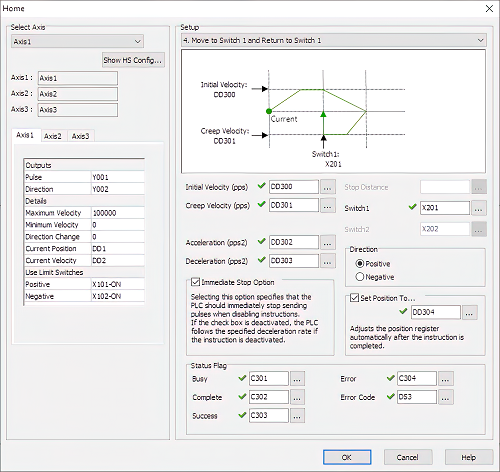

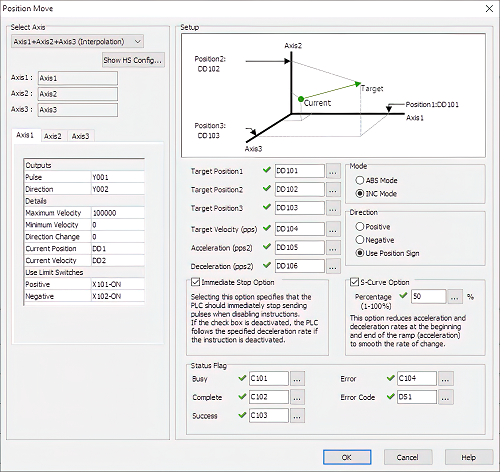

To address this issue, AutomationDirect has updated its popular CLICK PLUS micro-PLC with a compressed and simplified motion instruction set. Combined with high-speed I/O and other logic capabilities, the CLICK PLUS becomes a powerful platform for developing many types of motion applications. Some standard functions include:

- Homing

- Velocity Move

- Position Move

Making Motion Simple

Using AutomationDirect a CLICK PLUS micro-PLC with stepper motors makes it straightforward for users to implement the synchronized one-, two-, or three-axis combined movements needed for many types of machine automation applications. Check out the AutomationDirect.com website, and a series of videos describing how motion control can be a cinch.