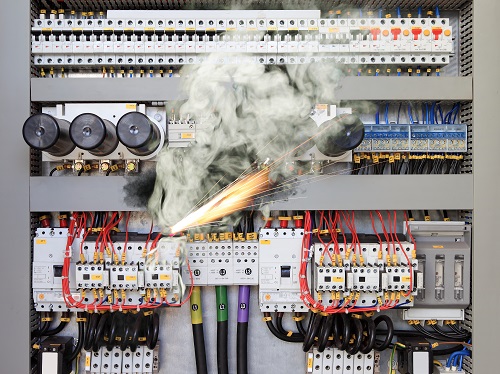

Most engineers, technicians and factory workers have a story about industrial injuries—such as shock or burns—that occurred on the plant floor. While most incidents happen during construction, maintenance or testing, they can occur during normal operations as well. Most can be prevented by using best design practices, and by following safe operating procedures and regulations.

Properly protecting a system or equipment is a key step in reducing costly downtime and equipment damages.

Brent Purdy, Product Manager for Power & Circuit Protection at AutomationDirect, provides more details in his Providing circuit protection for safety article, which appeared in the June 2018 issue of Applied Automation, a supplement to Control Engineering.

Purdy’s article examines common electrical safety scenarios, along with ways to protect personnel and machines.

Problem Scenarios

Proper short-circuit current and overload protection is required to protect against electrical system damages. During construction, an overload could shut down power. During maintenance, incorrect wiring or a misplaced tool could cause these current-limiting devices to activate. Purdy offers an example.

An incident occurred near the end of a week-long, plant-wide outage to perform preventive maintenance on switchgear. As part of the re-energization procedure, final safety testing was done to confirm all the busses and feeder lines were electrically isolated, and not grounded or shorted together. Even with all this testing, when the main site breaker was closed, it shorted out the switchgear. Later testing revealed someone inadvertently left a tool in a spot where it vibrated down onto the main breaker and was unseen. Without the current-limiting breaker, the short likely would have resulted in an explosive arc within the switchgear, and possibly personnel injuries from fire or arc flash.

There are more than 800 pages in the NEC, so this article only provides an overview of requirements to keep personnel safe from electrical shock and to prevent electrical fires. Using this article as a starting point and a blueprint, additional details can be filled in from the NEC and other sources to provide the circuit protection needed to ensure safety in an industrial plant or facility.

Branch Circuit Versus Supplementary Protection

Circuit protection is critical to protect a machine from currents greater than the machine’s or device’s current-carrying capacity. Proper electrical protection is the key to safely removing the effects of dangerous overcurrent due to short circuit, overloads, ground faults, voltage transients from switching surges and other abnormal conditions. Purdy explains how this works.

To provide this protection, it’s important to understand branch circuit protection versus supplementary protection. In general, branch circuit-rated devices protect the wires, and supplementary devices provide additional protection, but they are not sufficient to protect the equipment or load exclusively. Supplementary devices often are used for lower load equipment, internal loads, or as a simple additional disconnecting means.

Purdy points out that disconnects are another important safety component.

Though often overlooked, disconnects on industrial control systems perform the important function of ensuring the electrical feed circuit to a machine or system is completely de-energized to protect maintenance and operations personnel from electrical shock. Regulations require all power to the equipment must be shut off, locked out, and tagged out before servicing. Disconnects provide this functionality.

There are many general requirements, wiring practices, and grounding and bonding techniques to protect machines and personnel. To provide overcurrent protection, branch-circuit short-circuit, and ground-fault protective devices, supplemental overcurrent protective devices are needed.

Breakers and Fuses

UL 489-rated miniature circuit breakers and molded case circuit breakers are often used for branch circuit protection of feeder circuits downstream from a main disconnect, or for motor circuits. They are available in sizes ranging from fractional amps to about 800 amps, often with miniature form factors, and come in a variety of frame sizes, with 1- to 3-pole configurations.

Fuses are another good option to provide this type of protection, per Purdy.

Fuses usually are a more cost-effective method of overcurrent protection. They work well in applications where high fault current exists, and are commonly used to protect transformers, power supplies, and motors. Many branch circuit protection fuses are current-limiting and available with high interrupting ratings up to 200 kA. Fuses are available to meet UL and NEC code requirements and include time-delay and fast acting types. These fuses don’t wear out as there are no moving parts as with a circuit breaker, and contamination by dust or oil is unlikely.

A fuse’s biggest disadvantage is the need for replacement after operation, unlike a circuit breaker, which can typically be reset. Also, fuses inherently increase the chance of single phasing. Thus, while a fuse protects the system from a fault, equipment can be damaged by a single-phase condition, so key equipment should be equipped with blown-fuse detection phase monitoring devices.

Providing Safety from Surges

When it comes to shock or fire safety, surge suppression often is overlooked, but power surges cost U.S. companies more than $80 billion a year. Purdy says surge protection devices can help prevent these losses by shielding against small power spikes that damage equipment over time, and can also provide defense against less frequent but more serious major power surges.

These surge devices are selected based on the supply voltage, expected magnitude and rate of occurrence of power surges, and the number of phases in the power circuit. They provide inexpensive insurance from equipment damage.

In summary, Purdy says when correctly selected and applied, circuit breakers, fuses, and other protection components can help keep workers safe from injuries and machines from damage.

To read more articles about circuit protection, click here.