Online purchasing has taken over much of the consumer goods sector, and is now a viable option for many industrial automation products. The automation products used by machine builders, integrators and end users can be purchased either directly from the manufacturer, through distributors, or from an online store offering a variety of products from different manufacturers. Each approach has its advantages and considerations, and these were examined in detail in Control Design magazine’s March 2016 cover story titled “Why Buy Direct?”

What follows is a summary of the cover story, with the goal of providing assistance to those charged with deciding just how to specify, buy, implement and support their automation products.

Buying from a Manufacturer

Manufacturers know their products, which confers certain advantages. “The main advantage of buying direct from the manufacturer is the deep product knowledge,” said Lyle Rusanowski, CEO at Delta Technology, a custom machine builder in Phoenix, in the cover story. “Going direct usually makes sense when you are buying an end product that will be integrated into a complete system.”

But, not all manufacturers are up to speed on application-specific issues. “Since the manufacturer is mainly concerned with the product, its focus tends to be deep, not broad,” explained Rusanowski. “Most do not have application engineers that are focused on going broad and applying the products in many applications. If the conversation becomes application-specific, a detailed review of the requirements and specifications is necessary to ensure the products can do it.”

But, not all manufacturers are up to speed on application-specific issues. “Since the manufacturer is mainly concerned with the product, its focus tends to be deep, not broad,” explained Rusanowski. “Most do not have application engineers that are focused on going broad and applying the products in many applications. If the conversation becomes application-specific, a detailed review of the requirements and specifications is necessary to ensure the products can do it.”

However, buying direct from the manufacturer can be expensive since there is often no volume to leverage the sale against, cautioned Rusanowski in the cover story. The manufacturer has to cover all of their overhead and other costs through what’s often a small-volume sale, so prices can be high for all but very high-volume purchases.

But, results may vary depending on the particular manufacturer. “I’ve had the opposite opinion in certain cases,” related Leon Krzmarzick, senior manager of control engineering at Delta Technology, in the cover story. “Festo’s applications guys have been very good, and they’ve been able to offer us very good discounts. But we’ve never purchased Festo through a distributor. SMC, on the other hand, used to be direct, and now we are getting better pricing through distributors.”

“And then you have Allen-Bradley, who I noticed has relabeled other manufacturers’ products, and not being cheap, even with distributors,” added Krzmarzick in the cover story.

Factory-Direct

“At c3controls, we have found, the more control we have over every step of the development process, manufacturing, fulfillment and service, the greater the benefit is to the machine builder, said Geoff Taylor, president and CEO at c3controls in the cover story. “Our vertically integrated and factory-direct approach is innovative in its application to the electrical-controls marketplace where the vast majority of transactions are processed through legacy distribution channels or impersonal online warehouses.”

Taylor continued in the cover story. “We are able to offer expert support because we design and manufacture the products; and we are able to offer pricing that provides tremendous value,” he said. “This represents an electrical control product and supplier option that impacts the machine builder’s bottom line by improving cash flow and profitability—a business case that is unmatched in the industry.”

Factory-direct delivers the best value, noted Taylor in the cover story. “To accomplish this, you can’t attempt to be all things to all people by offering more and more products,” he related. “Attempting to do so without processes in place to ensure quality, availability, price and expert service will lead to diminishing outcomes for the customer.”

Factory-direct delivers the best value, noted Taylor in the cover story. “To accomplish this, you can’t attempt to be all things to all people by offering more and more products,” he related. “Attempting to do so without processes in place to ensure quality, availability, price and expert service will lead to diminishing outcomes for the customer.”

Factory-direct implies direct interaction with the manufacturer, but may include distributors. “This does not necessarily exclude the distributor,” said Taylor in the cover story. “A customer researching products is more likely to gain greater insight into the technology quicker by engaging the manufacturer of the product. They are best positioned to provide expert product and application support.”

Distributors can often provide service in some instances, but not without concerns. “Challenges arise when distributor affiliations with specific manufacturers or suppliers exclude products from consideration that would benefit the machine builder, both in the application and the bottom line,” said Taylor in the cover story.

“We have numerous productive OEM, manufacturer and distributor relationships across the country and internationally that are predicated on customer value,” concluded Taylor in the cover story. “No single manufacturer is able to supply and service all of the products used by the machine builder, system integrator or end user in their applications and operations.”

Buying direct from a manufacturer has its advantages, but other approaches may work best depending on the purchaser’s needs.

Purchasing from Distributors

“Distributors are interested in moving as much volume as they can,” noted Rusanowski at Delta Technology in the cover story. “This drives lower volume discounts and improves margins, so their focus shifts to applications.”

“Distributors are able to leverage volume, so we usually get much better pricing, and, if we can consolidate purchasing of many products through the same distributor, we get further discounts,” he related in the cover story. “The distributor’s account representative also usually tracks down and helps resolve any issues, should they come up.”

“A big advantage to using distributors is that they can get involved in, and be responsible for, proper product selection,” observed Krzmarzick in the cover story. “For example, servo-motor sizing applications can become complex, but a good distributor will help to size all components in the application and then stand behind that solution.”

We’ve looked at purchasing direct from manufacturers and through distributors, now let’s examine the third approach, buying from an online store.

The Online Option

”Purchasing from online stores is typically the lowest pricing that you can get, but you don’t have the face-to-face support like the distributors,” said Delta’s Rusanowski in the cover story. “Since we are a custom integrator, we usually need more support than the online stores can provide. However, for commodity type products, online stores are very cost effective, and we use them quite a bit.”

Rusanowski says not all online stores are equal. “Some sites do not make it easy to buy multiple products or multiple items, so we generally will move away from them. If sites have items in stock and we can get them quickly, we will buy from that site,” noted Rusanowski in the cover story.

“Another advantage of good online stores is that CAD models and technical specifications and manuals are readily available,” pointed out Krzmarzick in the cover story. “It is very convenient to go to a website, select the product and then immediately have access to the CAD model for the configured or selected product. Websites with good selection, configuration tools and accurate CAD models will continue to get our business.”

The Online Leader

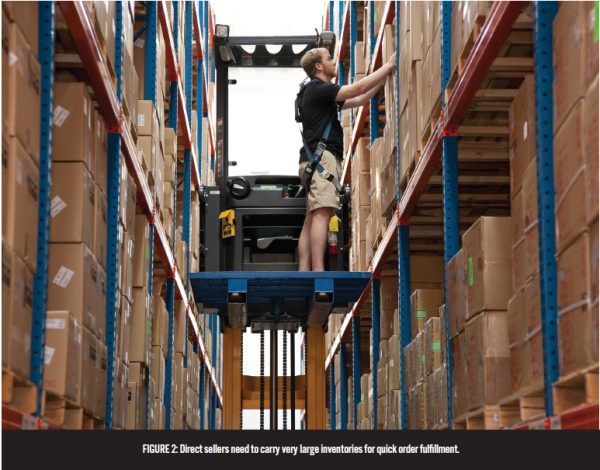

AutomationDirect’s sales in the United States and Canada are direct via Internet and catalog, with international distribution in other areas of the world.

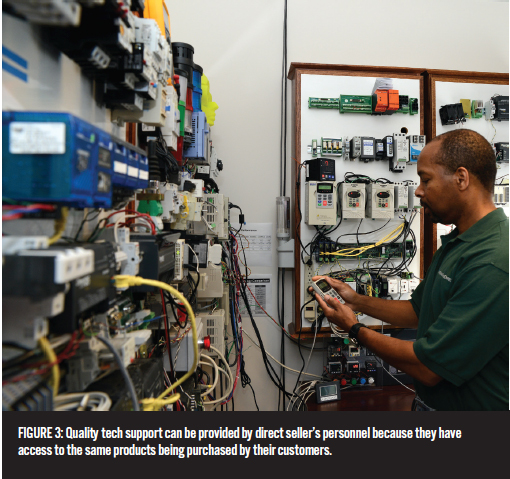

Tech support is a focus for the company. “Our technical support staff is fully trained on our own products and has won awards 15 years in a row for our main programmable products—PLCs and HMIs,” said Gary Marchuk, business development director at AutomationDirect, in the cover story. “Since our staff is supporting our own products, via phone or online, if the question gets too tough, our support staff has product engineers and developers at their disposal to provide answers in a quick and efficient manner as a backup.”

AutomationDirect provides information such as product specifications, manuals, certifications and pricing 24/7. “For most products we have product videos available that show a customer how a product is used or how it is programmed,” noted Marchuk in the cover story. “We offer 2D and 3D drawings of most products up front for evaluation and also provide the manual for free in downloadable form. For most programmable products, we allow the user to download the programming software for free to evaluate on their own time. In this day of instant information, we believe this is what most purchasers want.”

AutomationDirect provides information such as product specifications, manuals, certifications and pricing 24/7. “For most products we have product videos available that show a customer how a product is used or how it is programmed,” noted Marchuk in the cover story. “We offer 2D and 3D drawings of most products up front for evaluation and also provide the manual for free in downloadable form. For most programmable products, we allow the user to download the programming software for free to evaluate on their own time. In this day of instant information, we believe this is what most purchasers want.”

Online automation purchases are being considered with increasing regularity, observed Marchuk in the cover story. “With higher Internet bandwidths and customer access to the Internet, they can get anything they want the instant they want it,” he said. “There is little that most customers need that they cannot get from our Web store.”

What’s Best for You?

Delta Technology compares their purchasing experiences. “Having the distributor’s application support is like having extra engineers in-house to help you to solve problems,” said Rusanowski in the cover story. “When looking at costs, I can evaluate in terms of what value the distributor provides and compare that to the amount of time my team needs to spend to get the same information.”

Delta also purchases online. “The tools available from placing large orders to the tracking capabilities make this much easier to keep control of our supply chain,” he pointed out in the cover story. “Sales representatives and phone support are important when there are issues or when learning about line cards, but when you look at purchasing, I would estimate more than 90% is done via online orders.”

Some system integrators prefer online ordering. “My preference is to purchase online whenever possible, preferably direct from the manufacturer,” said Marshall Miles in the cover story. Miles is the managing director at system integrator Global Controls in Saint Charles, Illinois. “I like the immediate access to the specifications, pricing and availability, and anonymous access is the best without the need to register to use the portal. Whenever I have to talk with someone, they typically have an agenda and want to find out more about the project, usually fishing for something else to sell.”

Some system integrators prefer online ordering. “My preference is to purchase online whenever possible, preferably direct from the manufacturer,” said Marshall Miles in the cover story. Miles is the managing director at system integrator Global Controls in Saint Charles, Illinois. “I like the immediate access to the specifications, pricing and availability, and anonymous access is the best without the need to register to use the portal. Whenever I have to talk with someone, they typically have an agenda and want to find out more about the project, usually fishing for something else to sell.”

Like many others in the automation industry, Miles’s time is limited, so he looks for the most efficient purchasing process. “Once I have a clear path for a solution mapped out, the best way through is to stay hyper-focused and get that solution implemented,” he said in the cover story. “Anything else is a distraction. Distributors and manufacturers are almost always biased, and perhaps they should be. However, in my experience technical reps and sales engineers often have little practical knowledge to offer to our complex applications.”

“In my opinion, supply chain management is the most critical factor in delivering a project on time,” said Rusanowski in the cover story. “We work closely with suppliers that can help us to manage the supply chain and reduce its variability. By managing these relationships and building partnerships where possible, it helps to lower the overall project risk and improves the ability to satisfy the end customer.” [hozbreak]

Dan Hebert, PE is an automation industry veteran with over 30 years’ experience in engineering, management and editorial positions. He has worked for end user, system integration, OEM and publishing firms. He is presently a Principal with ControlsPR, a content creation agency. Dan holds a BSEE degree from ULL and an MBA from UCI, both granted with honors. He holds a patent for a Control System for Flue Gas Conditioning, and is a registered Control Systems PE in California and a registered Electrical Engineering PE in Louisiana. He is a member of Beta Gamma Sigma (MBA Honor Society), Eta Kappa Nu (Electrical Engineering Honor Society), ISA and Mensa.

Dan Hebert, PE is an automation industry veteran with over 30 years’ experience in engineering, management and editorial positions. He has worked for end user, system integration, OEM and publishing firms. He is presently a Principal with ControlsPR, a content creation agency. Dan holds a BSEE degree from ULL and an MBA from UCI, both granted with honors. He holds a patent for a Control System for Flue Gas Conditioning, and is a registered Control Systems PE in California and a registered Electrical Engineering PE in Louisiana. He is a member of Beta Gamma Sigma (MBA Honor Society), Eta Kappa Nu (Electrical Engineering Honor Society), ISA and Mensa.