Automation is a key component when developing strategies to help customers reduce their operating costs.

Many times when making buying decisions, people look only at the initial price of an item without considering other factors that contribute to the overall cost of owning that product. For example, a certain laptop may seem like a great deal—before adding the cost of the operating system and the software, and the extra memory needed to augment the unit. Moreover, the low initial price might mask the fact that the cheap laptop will become obsolete much faster than a more expensive unit, or that it may not be robust enough to withstand the rigors of travel.

This example is similar to purchasing decisions that must be made when buying an industrial machine. In addition to the initial price, expenses that may or may not occur during its service life need to be calculated to determine how much the machine will cost over its lifespan. This is called the total cost of ownership (TCO) and is a critical factor in the purchasing process of a machine, but one that is often overlooked.

In addition to the initial costs, such as the purchase price and the cost of integrating the machine or equipment into the overall control system, buyers need to consider the long-term operating costs before making a purchase. A bargain isn’t a bargain if it will require unusually high amounts of energy and maintenance. Buyers must also consider additional factors in the TCO equation: downtime and changeover expenses, off-spec product, floor space requirements, insurance, financing costs, training, security and safety, among other expenses.

Unfortunately, these considerations aren’t as easy to make as they are for a consumer product, such as a laptop or a smartphone. Machine builder OEMs need to realize the features that reduce customers’ TCO may increase the cost of their machines. Corresponding higher prices may scare off customers, so OEMs need to decide how to best educate their customers about long-term savings in order to justify the higher purchase price.

Importance of Energy Efficiency

As energy costs continue to rise, most customers are looking for greater energy efficiency from their machines. Most of a machine’s operating costs come from its energy usage, making energy efficiency an important selling point.

OEMs are responding by building more energy efficient machines. In order to improve, they need to see exactly how energy is being used by their machines. Monitoring energy consumption can provide the knowledge as to where improvements can most easily be made.In the Control Design January 2012 story “Design for TCO”, Carl Henning, deputy director of PI North America (www.us.profibus.com) explains an approach to uncovering energy costs by using Profienergy, a function of Profinet. Henning says, “One of the features of Profienergy is the ability to format data into useful information about energy demand. This information can be used to avoid demand peaks.”

Extending a Machine’s Lifespan

Monitoring also provides valuable information beyond energy usage that may help machine builders provide better TCO for their customers, such as how to extend the life of a machine by protecting it from damage.

Embedded intelligent devices monitor motor currents, vibration and torque signatures, which help machine builders design machines with protective functions against these problems. By protecting against the damaging effects of electrical and other hazards, they can provide long-term equipment protection that extends the machine’s life and reduces the frequency of equipment replacement.

Looking at Hibernation in New Ways

Including a hibernation state is a valuable approach to improving TCO by reducing operating hours and energy use. In the Control Design January 2012 story “Design for TCO,” Derek Jones, marketing manager at Lantech (www.lantech.com) comments, “Our machines only run when product is fed to the machine. During downtime, the machine is not using much power at all.”

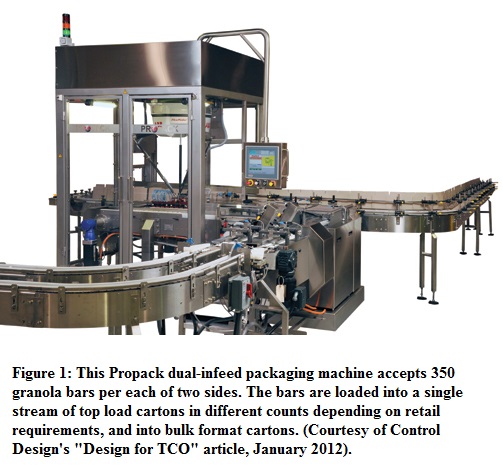

The Control Design article also looks at how the Canadian company Propack Processing & Packaging Systems (www.propack.on.ca), which builds robotic collators to feed topload, endload and multipack packaging machines, uses hibernation to improve TCO. (Figure 1). Propack’s machines typically run three shifts per day. Chris Follows, president, says “If no product is available, we turn off all the conveyors that feed the machine. This also ensures cartons are not damaged due to conveyor friction.”

A hibernation cycle can go beyond reducing energy costs for operating the machine. By reducing the time a machine is running at full load, users also reduce the amount of heat generated throughout the operations shift, thus lowering cooling costs.

Many customers may not be aware of the machines’ features that can help them save energy, such as automatic sleep mode. According to the Control Design story, a recent study in the automotive industry quantified the potential savings of putting systems into a sleep, hibernate or standby mode when not actively producing value. The analysis concluded potential savings of up to 30 percent could be achieved.

Hibernation can be a good way to reduce energy costs, but it can’t be simply added without carefully reviewing how it may affect other systems within the plant. Determining how to design and implement hibernation states require careful study, such as determining when to save energy by shutting the systems down, or when it’s better to leave them on.

Machine builders also need to examine the effects from the plant floor to an ERP system. One way to ensure a hibernation scheme is compatible with workflow and other production realities is to transfer I/O data to an ERP or MES.

Automation Keeps Costs Down

The calculation of reducing customers’ TCO but maintaining competitive machine pricing is a careful balancing act for industrial OEMs.

The latest automation technology can help these OEMs meet customer requirements without having to sacrifice their profit margins.

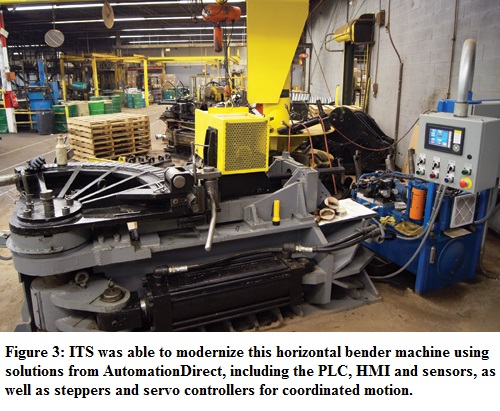

In the Control Design story, Howard Dittmer, vice president of engineering and technology at Arpac, maker of packaging equipment in Schiller Park, Ill. says, “Automation is a key ingredient in providing the flexibility that customers demand in our type of equipment.” He adds, “Modern industrial controls allow us to produce core machine designs that we’re able to customize to fit a wide range of applications.” (Figure 2)

Flexible Manufacturing

Although the features and functionality of automation technologies have been increasing significantly, their prices have remained relatively constant. This is good news for OEMs because the relative cost of automation actually is getting smaller, unlike mechanical components such as gears and linkages. Therefore, automation technology improvements are good ways for OEMs keep their costs down, while delivering better products to their customers.

The ability to develop more flexible designs is a good example of how automation helps improve TCO. “For example, if an infeed can be modified through automation to be flexible to accommodate a 12 or 16 inch opening, this can become a standard single product, rather than having a 12 in. machine design and a 16 in. machine design,” explains Michael Gurney, principal at system integrator Concept Systems (www.conceptsystemsinc.com) in the Control Design story.

Reducing TCO in Existing Machines

How can TCO be lowered for existing machines in service? Upgrading the control system is one of the best ways to reduce TCO on an existing machine. It eliminates the need to replace expensive machinery, which often includes structural steel, motors, sensors, robots, conveyors and other systems.

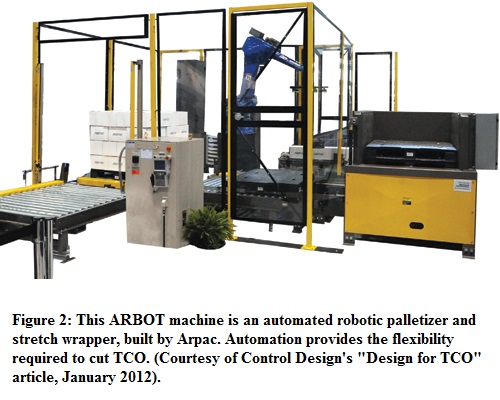

The Control Design story takes a look at how Industrial Technology Solutions (ITS), a system integrator in Columbus, Ohio, saves customers money by updating older control systems (Figure 3). Design engineer Brian Engle says, “If the equipment is not functional, then the manufacturer isn’t making money.” He adds, “The advanced diagnostics and interfaces that automation can provide are, in my opinion, the best use of automation for an end user.” (See the aditional story below for more details on this ITS application; visit Web site at: www.industrialtechnologysolutions.com for other applications.)

Outdated controls often raise operating costs due to their inadequate operating efficiency, higher maintenance costs and shutdowns that affect production. For example, an OEM recently discovered the benefits of adding a motion controller to reduce costs. In this case, a plant used some high-speed valves that cycled often, and the cushions that the valves sealed against would often wear out, requiring the whole plant to be shut down while the cushions were replaced.

A motion controller was added to properly accelerate and decelerate the valves at high speed without causing impact of the valve seat at the end of stroke. This relatively simple step helped the plant eliminate the three shutdowns per year that occurred prior to the upgrade, resulting in measurable and significant cost savings and reduction in TCO.

Rethinking Mechanical Line Shafts

In addition to control systems, mechanical line shafts are also good candidates for upgrades in order to reduce TCO. One company found that replacing mechanical line shafts with individual servos greatly minimized the setup time of a machine. Its client had a food-processing machine for which each product change required up to half a day just to tweak mechanical cams of a line shaft to ensure proper timing of the machine.

By replacing the mechanical line shaft and cams with individual servos, the timing is now stored as a product recipe; it’s simply recalled with the press of a button on the HMI for a product change. The increased production flexibility and reduced downtime for the customer quickly achieved payback for the slightly higher initial hardware cost. However, caution must be taken when using servos as replacements, especially if a design is optimized for a pneumatic or a cam-driven mechanism. In this scenario, costs are likely to increase rather than decrease. On the other hand, if a new design is optimized to take advantage of the functionality offered by the servos, the costs are diminished.

Another great way to reduce unscheduled and even required maintenance costs is by upgrading from older technologies like line shafts, pneumatics or chain drives to servos and steppers.

“We’re upgrading a seed-packaging machine from a chain-drive system with interconnected timing gears and belts to a completely modular design using independent steppers and servo controllers from AutomationDirect for coordinated motion,” Engle of ITS says. “The existing system is extremely difficult to adjust, as one adjustment leads to every other aspect of the process running at a different speed. Changing to steppers and servos will eliminate the problem.”

Educating Customers

As mentioned in the beginning of the article, too many buyers only look at the initial purchase price, not all the extra costs that can turn a bargain into a money drain. Educating customers about how the initial extra cost from new technologies can help them save money over the lifetime of the machine can be a challenge for OEMs.

The first steps are to understand each customer’s needs, and to then find the right solution for that customer. OEMs need to take the time to help the customer recognize how the total cost of a certain machine is more than just its purchase price. Using a customer’s own numbers instead of a general estimate to show how the machine can reduce labor or maintenance costs helps them to better visualize potential savings.

Engle from ITS explains how using a customer’s own data is more effective than simply giving them general figures. “If a company tracks maintenance and equipment downtime, it’s fairly simple to show payback,” he says. “Most manufacturers feel comfortable with numbers coming off the equipment and can schedule accordingly. They demand a solution that will provide them the ability to minimize production loss and maximize profit. This can be proven to do so through their own collected data.”Lastly, it’s important to note that not every customer needs every feature. Automation technology is a big factor in reducing TCO, but most clients don’t need all the latest technologies. OEMs must determine which features and technologies will help their customers achieve their goals, and eliminate superfluous features. This doesn’t just help to close the sale; it also helps customers achieve their specific goals, increasing the likelihood of repeat business.

Making Processes and Automation Easier

There are times when a perfectly good machine is replaced, when the better alternative would be to simply replace the control system. Brian Engle, design engineer at Industrial Technology Solutions (ITS) gives a good example of this when discussing a horizontal bender at a conduit manufacturer customer.

The horizontal bender required seemingly endless adjustments that dragged down productivity. It was controlled with manually operated hydraulic valves that had to be manipulated by two operators to achieve the necessary bend angle. A hard limit switch was used to control the travel of the bending die. Travel had to be adjusted constantly for variations in the pipe size and inconsistencies in the material.

The process of segment bending needed very precise control to achieve a quality product. Operators had to make several precise smaller bends while moving the pipe forward in the shoe. In addition to a long setup time, an enormous amount of scrap was produced before good product could roll off.

“If a job calls for, say, making 90 degree elbows with a 60 inch radius from 2 inch galvanized rigid conduit, there is no standard shoe for that. So this machine is used to make small quantities of non-standard products,” explains Engle. Instead of sticking with the cumbersome old process, the manufacturer asked ITS to modernize the control system with an HMI, PLC and sensors from AutomationDirect. (Figure 3)

“The new system uses a magnetic encoder on the bending die to track bend angle while analyzing the bending shoe to compensate for pipe inconsistency and spring back,” Engle explains. “A linear cable position encoder allows the bending shoe to measure pressure or positioning sensing.”

The new HMI is an integral part of the process as the gateway for the operators to interface with the PLC. Maximum product output is now achieved as a result of the system’s advanced diagnostics that shorten downtime and optimize setup procedures. The manufacturer can measure the improvement in TCO directly in terms of reduced scrap, quicker turnaround on custom jobs, and reduced labor for setup and operation.

ITS understands the goal of automation is to make work easier for the user. “Troubleshooting a machine can be a daunting task for most plant personnel. We try not to overcomplicate that process with unnecessary sophistication. When the situation demands it, a more complex control system can be implemented and easily justified by its advanced diagnostics and intuitive interfacing techniques.”

By Christine Lesher

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Posted: Dec. 12, 2012