When selecting the right shampoo, what factors do you consider? Scent, ingredients, cost? How about packaging? That’s right, packaging. For the follicly-challenged, like myself, packaging may be a real decision maker. After all, luster, sheen and volumizing abilities are kinda lost on me. For most, packaging is an afterthought, if it is a thought at all. But packaging can be the most complicated aspect of the manufacturing process. One that can require specialized machines customized to a particular product design. And that’s exactly where Riada Equipment stands out. Based out of Winder, GA, Riada has been solving problems for cleaning product, food and beverage, textile, cosmetic, lubricant, and glue and adhesive customers since 1984. The company offers new bottling equipment, and also remanufactures existing customer equipment.

When asked where the exotic company name came from, owner Ross Adair said it was just his last name turned backward. How clever. When a long-time customer ran across a difficult bottling application, they turned to Riada to solve it, calling on that very cleverness.

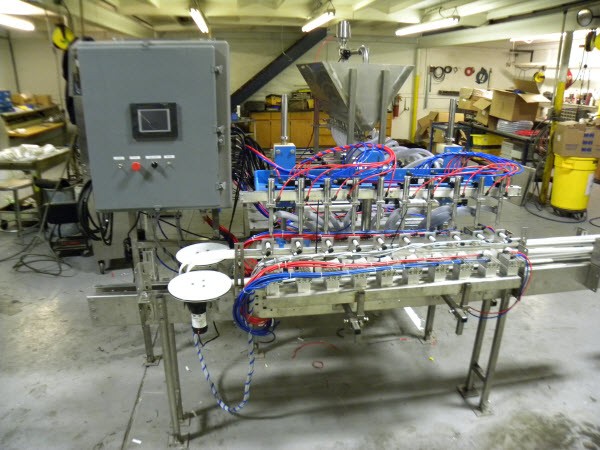

The difficulty in this particular customer’s case centered on uniquely-shaped shampoo bottles. The oval containers precluded stacking, and also conveying bottle-to-bottle. Instead, each bottle had to be indexed and then clamped individually for the filling sequence. To accomplish this, Riada decided to use a programmable logic controller and associated system components from AutomationDirect.

Controlling Machine Motion

The machine entry section consists of a set of DC motor-controlled round spacing wheels that move the bottles onto the machine belt conveyor for filling. Running at a speed slightly less than the belt conveyor, the feed wheels space the bottles at the correct distance for the fill nozzles and bottle clamps. The belt conveyor speed is regulated by an AutomationDirect GS2 series AC drive.

Round-body style entry and exit pneumatic gate cylinders are also supplied by AutomationDirect, and they control the overall 10-bottle group container flow into the machine, and out of the machine to downstream operations.

As the bottles enter the machine, they are counted by an AutomationDirect MVP series retro-reflective photo eye. If the machine is set up for a ten-bottle run, then ten bottles are counted on the way in. The bottle count is decremented as bottles exit the machine, and the machine cycle is halted if the total count doesn’t reach zero.

A set of NITRA brand E-Series rod-guided pneumatic cylinders is located at each of the ten fill stations and is used to clamp and hold the bottles. This dual-rod design translates the force of the air into precise linear motion and minimizes any side-to-side movement. This is critical to the clamping sequence as it minimizes clamp-settling time.

An MV2-series photo-eye at each station individually detects the presence of a bottle and controls the clamping sequence. Since space in the dispensing area is at a premium, the MV2 diffuse type photo eye was used at each station to sense the presence of a bottle. This type of sensor eliminates the need to mount either a reflector or receiver on the other side of the sensing line.

NITRA pneumatic equipment is prevalent throughout the machine. An AFR series filter-regulator provides the machine with clean air at the right pressure, and Riada added a 3rd party receiver tank to provide excess capacity and minimize any drops in air pressure regardless of the real-time air load, ensuring consistent cycle times.

Manifold-mounted NITRA AVS-5 series 5-port 4-way solenoid valves provide the air control function required by the double-acting pneumatic cylinders. MLA series air header manifolds were added at the machine front and rear to distribute air with minimum piping runs, with the result being higher air pressure and more consistent cycle times.

Dispensing Operations

Filling the customer’s containers with product is the primary job of the machine. All equipment with surfaces touching the product meets FDA specification, including the stainless steel metering cylinders, and the shut-off stopper cylinders at each nozzle.

Supplying the force to move those cylinders are D-series NFPA tie rod cylinders. At the rear face of each tie rod cylinder are threaded rods and handles. Each rod travels through customer-supplied holes, and penetrates the rear face of the tie rod cylinder to provide a stop for its piston.

Manually adjusting the rod length varies the stroke of the tie rod cylinder, which in turn varies the volume dispensed by the stainless cylinder, a very simple yet effective design. Different color pressure and exhaust tubing separates the lines to facilitate tracing for troubleshooting.

Control and Operator Interface

The entire machine sequence is controlled by a DirectLogic DL-06 programmable logic controller. This brick style unit contains both the CPU and sufficient I/O to meet the machine requirements. A six-inch EA9 series color touch-screen C-more human-machine interface (HMI) allows for flexible machine product and cycle time setup. The HMI is used to set up various timers and variables for the filling process. It’s also used to control machine start and stop, minimizing the need for pushbuttons.

Besides operating screens, a maintenance screen is included. This screen allows operators to run the machine dry for testing various components and operations. Typical dry runs include clamping and unclamping of bottles, raising and lowering fill heads, and running the machine through its entire sequence without dispensing any product.

Test and Results

Shop test was performed at the Riada facility in Winder, Georgia. Minor PLC program changes during shop test were done remotely by Riada’s systems integrator, Systems & Controls of Lenoir City, TN. The integrator’s PC was connected remotely to Riada’s shop floor PC running DirectLogic programming software. The connection was made over a wireless plant network at the Winder location. Successful shop test and product run-off with the customer allowed Riada to receive final signoff prior to shipment, a critical milestone. The machine has been running for two shifts a day since November 2014 without interruption. Due to these successful results, the customer ordered and Riada delivered clamping systems for two of the customer’s existing machines.