Industrial automation safety designers should implement a hierarchy of controls.

Josh Draa, PLC Product Engineer at AutomationDirect, wrote an article for the August 2022 issue of Applied Automation. The article is titled Implementing a Hierarchy of Automation Safety, and it describes the importance of project and operations.

Responsible industrial automation safety design requires a combination of the right products, design practices, and operational training. Even if personnel are not directly involved with safety design, they will benefit by having a good understanding of the concepts involved.

The first step in achieving a safe workplace is to perform a risk assessment to identify potential issues, and the goal then changes to lowering risks through mitigation.

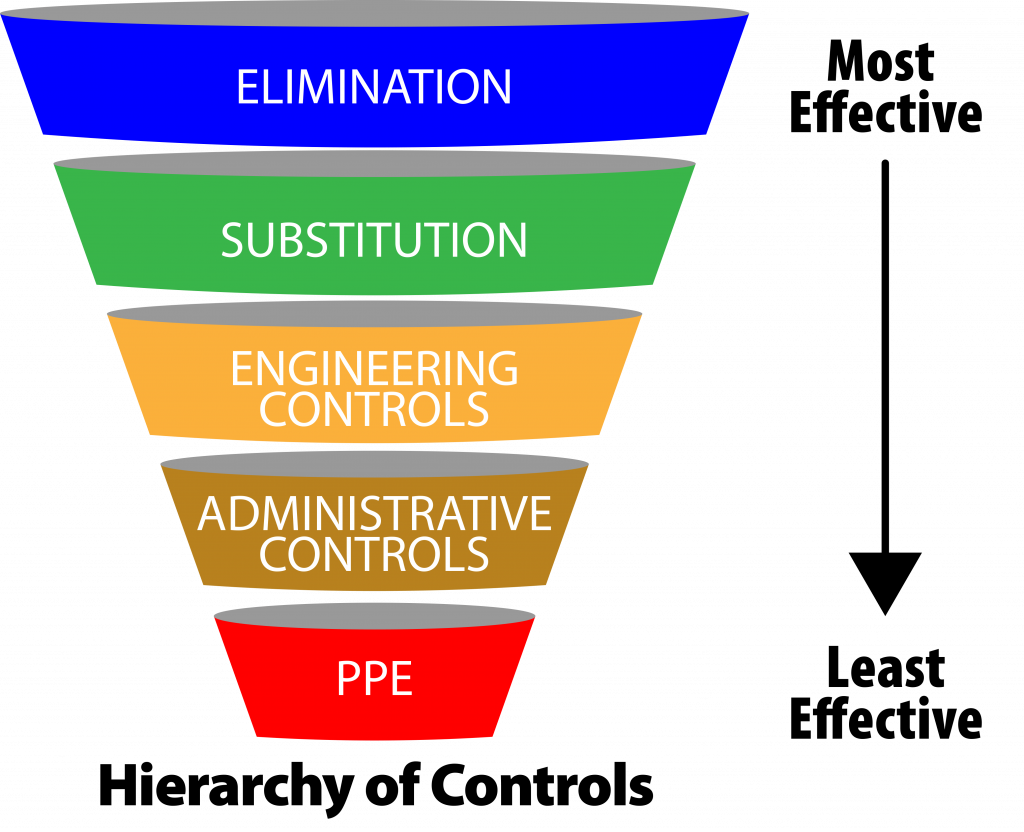

Many regulatory agencies—such as OSHA and NIOSH—as well as codes and standards, are associated with industrial safety. Executing safe design requires consideration of several layers in a “hierarchy of controls” to provide a complete solution.

These controls represent the steps, in order of preference, that users should perform, to reduce possible hazards:

- Elimination: Removing or deleting a potential hazard is the best option, but often is not viable.

- Substitution: Replacing a hazard with something less severe or requiring less frequent access.

- Engineering controls: For modern equipment, applying simple or complex controls is the most practical way to achieve risk mitigation. This can include physical measures like gates, guards, and cages, or more automated hardware/software solutions involving sensors, interlocks, energy removal devices, and safety controllers.

- Administrative controls: Training programs are always recommended to ensure all personnel are aware of the hazards and follow best procedures.

- Personal protective equipment (PPE): PPE, such as safety glasses and gloves, is a standard staple, but also a method of last resort.

Safety designs must be validated to ensure that risks are truly mitigated. Because some mitigation efforts may create new hazards, additional review cycles must be applied in an iterative manner to re-assess the situation.

Creating safe systems is an ongoing process, and all team members share responsibility. AutomationDirect offers a wide range of safety products to help end users find exactly what they need so they can create the safest possible systems.