Safety Controllers are often a better option than multiple safety relays, especially for more complex applications.

Larry Reynolds, product engineer for sensor and safety products at AutomationDirect, wrote an article for the February 2019 issue of IMPO titled Safety Controllers Simplify Systems. Here’s a summary, click on the link above for the full text.

Reynolds writes that multiple safety functions must be performed in most industrial machine and process automation applications, and in these instances, there are many benefits to using a single modular integrated safety controller instead of multiple safety relays. A leading advantage is their high level of customization through programming.

These controllers provide a high level of fail-safe operation for applications where personnel and machinery require protection. They typically consist of a master unit configured with PC-based programming software.

The benefits of using a safety controller start when comparing it to the cost and effort of integrating two or more safety relays. In many cases, a safety controller costs about the same as two to three safety relays and eliminates the integration effort.

Some safety controllers are standalone, but most can be expanded with modules to add significant capabilities. With the proper modules specified, safety controllers can support over 100 inputs, 30 or more safety outputs, and dozens of status outputs.

This AutomationDirect MOSAIC safety controller is modular, expandable and configurable, and can be used for managing all safety functions of a single machine or an entire plant.

While some safety relays may include a fieldbus option for limited status monitoring, expansion units in safety controllers permit connection of the master unit to most of the commonly used industrial fieldbus systems to communicate a wide variety of parameters, says Reynolds.

This enables diagnostics, I/O point monitoring and safety output status to be digitally communicated to automation controllers using EtherNet/IP, Modbus TCP, EtherCAT, Profinet, Profibus, CANopen, DeviceNet, CC-Link, Modbus RTU and other protocols.

The fieldbus capabilities of safety controllers can save a significant amount of wiring by eliminating the discrete status signals (status outputs) often connected to an automation controller. The fault monitoring capabilities built in to the safety controller can also save on wiring. If any point fails, the safety controller will failsafe and can be programmed to only shut down certain parts of the overall safety system. Safety controllers also come with other benefits.

There are many sensors and functions used in a safety system to protect persons and machines, and the ability to handle a wide range of safety functions is another benefit of a safety controller. It’s a single, flexible and expandable device for monitoring and controlling many different types of safety devices.

Programmable Safety Benefits

Whether it is used for managing all the safety functions of a single machine or in an entire plant, the programmable features in a safety controller can scan multiple safety sensor inputs to create multi-zone and multi-function safety systems. Reynolds says the software in these safety controllers can be used to create complex safety functionality using logical safety blocks such as safety guard lock, muting, timer and counter.

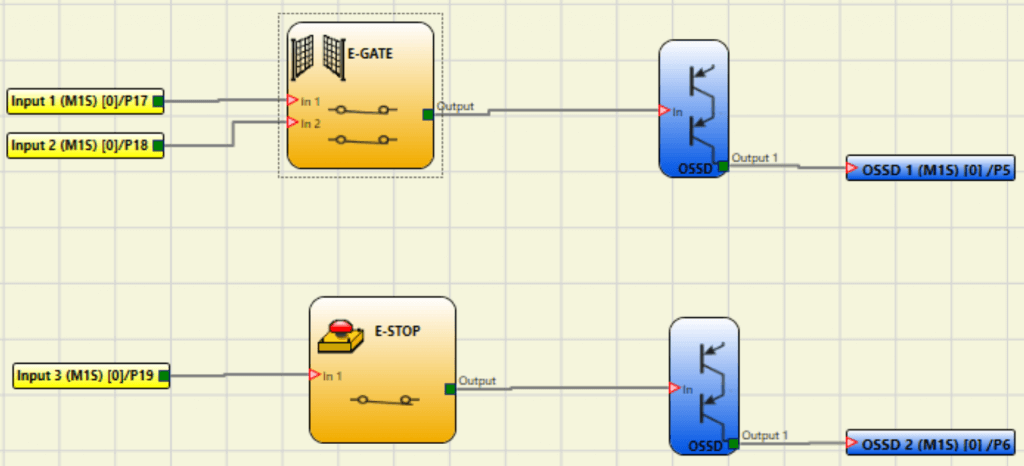

The software allows configuring, programming, simulation and monitoring of the safety system using a simple and intuitive graphical interface. The application safety software is used to configure logic diagrams of the connections between the master unit and the expansion modules, as well as the safety sensor inputs and safety and status outputs.

MSD software from AutomationDirect is used to program safety controllers using an intuitive graphical interface with drag and drop configuration tools.

This configuration is performed offline on a PC and downloaded to the master unit.

A completed safety program must be validated and tested. Some controllers provide rules-based guidance and safety reports to help define the system and programming, which helps with validation. After validating and downloading the program to the safety controller, and connecting all the safety devices in the field, the system must be tested to verify correct operation.

When selected and configured correctly, a safety controller is often the best solution, particularly as complexity and the required number of safety relays increases. Care must be taken when configuring and testing the controller, but programming software provides a number of functions to aid in the performance of these tasks.