How are you keeping your operators’ hands, head and other body parts away from running machinery? Suitable mechanical guarding and guard switches are a good place to start—whether they are tongue interlock, non-contact, hinge interlock, cable pull or other types of safety switches. However, for improved protection of operator body parts from operating machine hazards, be sure to also consider the following safety hardware:

- Light Curtains

- Trapped Key Systems

- Safety Relays

Close the Curtain

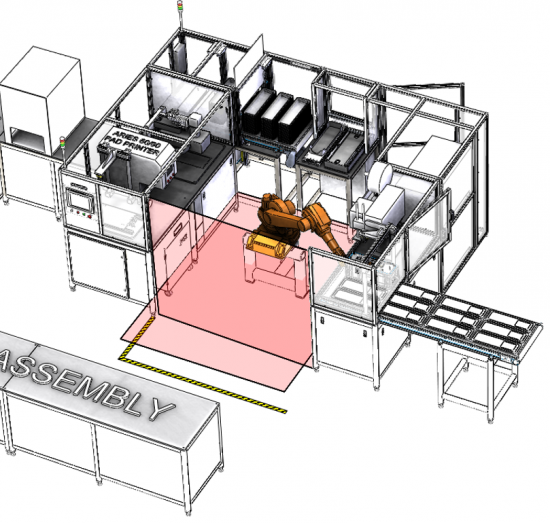

Not only can a safety light curtain protect an operator from a machine hazard, it can also be used as an area guard. It can scan horizontally across a floor to keep an operator from standing inside a hazardous area, or vertically across an opening as an access control safety barrier.

A light curtain’s transmitter sends out parallel beams of infrared light to a receiving unit. Stick your head or hand in it and it stops the machine. Light curtains are great for point-of-use protection where the operator has to reach through the light curtain every cycle such as on a press or other manually loaded automated assembly machine. They are also good for making sure no one is inside a guarded area when a machine is running.

When using light curtains, don’t forget to:

- Determine the size of the body part to detect and adjust the beam spacing between the parallel beams (resolution) accordingly

- Position the light curtain a suitable distance from the hazard to prevent an operator from quickly reaching through the light curtain into the hazard before the machine can stop

- Pay careful attention to the light curtain height so the operator cannot reach over it and into a hazard

I Got the Key, So You’re Locked Out

Another safety option is a trapped key system. Picture two “keys” inserted into a module, each having a metal tongue that plugs into a grooved opening and locks into place. Each key needs to be in place before a machine can operate. And when the machine is shut down, you can pull one of the keys and use it to open any door in the guarded area. See it in action in this video!

This type of system provides a high level of safety for both machine operation and maintenance, as machines can’t run unless all keys are in place, and guard doors can’t be opened without a key. For further security and as shown in the picture, each key can be secured in place with a padlock.

Safety Relays Tie It All Together

Most robots and machines require mechanical guarding position switches, light curtains, trapped key safety systems, and/or other safety related components. The safety relay system ties all of these components together. When a guard is opened, the safety relay, and possibly related power contactors, must reliably remove motion-causing energy from the machine.

A simple single-function safety relay is an excellent choice when there are just a few guard switches and one E-stop push button. However, if your safety system has more than three safety devices, or has multiple safety functions such as separate E-stop and light curtain circuits, a multi-function safety relay should be considered as it will simplify implementation, cut cost and provide flexibility.