There are many safety devices available to ensure machine safety and to detect personnel entering unsafe areas. Cable pull switches, safety light curtains and interlock switches (non-contact and the many types of tongue interlock switches) are just a few of them. Most of you have probably heard of, or used, these devices in some capacity, but one of the newer safety devices on the scene, that you may be unfamiliar with, is the safety laser scanner. A safety laser scanner has a very wide monitoring window that can detect people or objects in its protected area. When connected to a safety controller, these scanners will put the machine into a safe state upon an intrusion of this protected area.

What is a Safety Laser Scanner?

In short, a safety laser scanner is similar to a motion detection sensor for a home security system but much more sophisticated. Instead of just detecting motion, it detects if there is a person, animal or object, etc. in the area it is set to protect. Like a motion detector, both devices will be set up to monitor an particular area, but with the motion detector if you walk into its monitored area and stand very still it will detect nothing is present. With a safety laser scanner, you won’t be able to fool it. Safety laser scanners also use lasers, not infrared light or sound waves to determine an intrusion to the area.

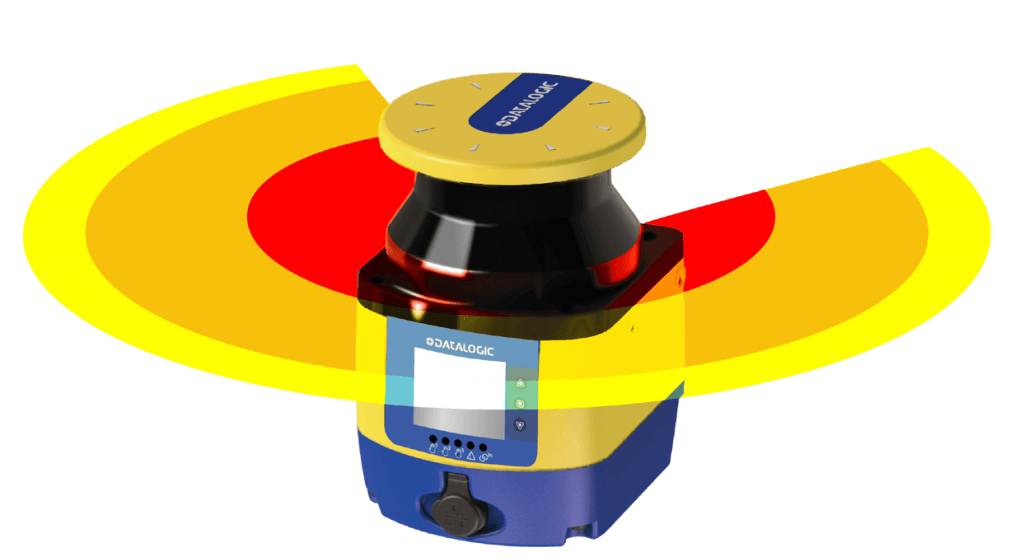

Safety laser scanners are intelligent devices that can be programmed to have multiple levels of protection, configurable alarms, dust filtering and even muting on some models. Their wide-angle monitoring area, approximately 275 degrees around the unit, can extend and detect objects around 40 meters away.

Safety Laser Scanner Applications

Why would I want or even need to use a safety laser scanner? Well if you look at the price tag of a safety laser scanner alone, it might scare you away. However, there are several cases where they make the most sense to use over other devices.

One application would be a mobile application, in particular, an automated guided vehicle. Usually referred to as “AGVs” but also know as the little car-bot things that look like something out of a science fiction movie. Normally, these AGVs operate in areas where people are walking around and where other machinery could be present including other AGVs. So, how do you prevent these bots from hurting someone or another piece of equipment? To ensure a wide range of coverage, you could place sensors all over them and run all of those wires on a tiny mobile unit to one or more relays or a safety controller. However, a much cleaner and less cumbersome alternative would be installing a safety laser scanner, configuring it, and connecting it to a safety controller. You might need two safety scanners if the unit needs horizontal protection that covers 360 degrees around it or even more if the AGV is something specialized like a forklift. However, for most applications, just one or two scanners will get the job done.

Another great application would be in a robot cell. The traditional method of protection around a robot cell is to use safety gates or cages around the cells and have the doors interlocked with safety interlock switches. Another method is to use multiple light curtains around the cell. One or two safety laser scanners can do the job of either of those approaches and cost not just less money but a lot less time.

Think of your typical modern manufacturing facility. Oftentimes these facilities are going through minor to moderate changeovers every year and major overhauls every 3-5 years. Just moving light curtains and lining them up again can be a real pain and taking down and putting gates and cages back up eats up a lot of time. Relocating a safety laser scanner is a cinch, basically you just place it in its new location and connect it back up.

Another way a safety laser scanner can be benefitial, is to set it up to behave like a very large light curtain. Most models of safety laser scanners support horizontal and vertical monitoring which allows them to be applied in this manner. A safety laser scanner can be set up in a vertical mode and take the place of what would require a very large safety light curtain.

Although they may seem expensive, one safety laser scanner can usually do the job of many other devices with much less effort. These specialized safety monitoring devices offer a practical, cost-effective way to protect a specific area when used in the right application.