Most people wouldn’t consider cable ties as art but this creative Italian-based company, SapiSelco, has made the production of industrial cable ties into an art form in both its design and development of its unique ArtisTie program.

With a love of art that dates back thousands of years, northern Italy is home to ancient art, history, scientific discoverers, and art lovers. Appropriately, this is where SapiSelco, or SAPI as it was originally known as, was founded in 1950 by Romeo Griggio as a sub-supplier and subcontractor manufacturing thermosetting resin moldings for early plastic materials like Bakelite. In the 1960s, the company continued honing its expertise in plastic materials and specialized in injection molding and developing new technologies.

By 1970, SAPI continued to expand as Romeo Griggio’s son, Stefano, used his background in engineering, to focus the business on the manufacture of cable ties. The company handled the production from start to finish, including independent equipment design, selection of raw materials, production process, and product quality control. By the 1990s, SAPI became an independent entity with direct sales of its own line of products under the brand name SELCO Fissaggi. Less than a decade later, SAPI took over the SELCO brand and reorganized the structure of the two companies into one – SapiSelco as it is now known. Today, SapiSelco is one of the leading companies in the cable tie sector.

With 18 million cable ties leaving their production facilities every day, the SapiSelco team has the confidence that each tie will provide the performance and quality that customers have come to expect from the SapiSelco brand.

A History of Creation

Capitalizing on his father’s business, Stefano Griggio carried on the family company and in the 1970s expanded the first site, adding state-of-the-art technology for the processing of thermosetting plastics. Over the last few decades, SapiSelco has become one of the most important injection molding companies in Italy. Today, Dr. Federico Griggio and Dr. Giacomo Griggio, managing directors of SapiSelco, alongside Chairman Mr. Stefano Griggio, run the family business, now in its third generation. Adding a maternal touch, is Mrs. Loredana Griggio who worked alongside Stefano in building the company. Still active in the family business, she now works as the Credit Manager. Capitalizing on 65 years’ experience and a new team at the helm, SapiSelco is ready to face the future with great expectations.

Proud to be 100% Italian Made

The entire SapiSelco operation is located in Padua (Padova), Italy near Venice. All of its products, including the mold productions are based at these facilities. “We are proud to say our cable ties are manufactured 100% in Italy,” said Dr. Giacomo Griggio, MD and Sales Director for SapiSelco. Three units of the company produce their famous “Made in Italy” products. Unit 1 has the administrative and management offices, production, logistics, and research & development lab. Unit 2 has additional production, logistics, and R&D departments. Unit 3 houses more logistics offices. “We carefully maintain our quality standards so we can say ‘Made in Italy’ with confidence and pride,” said Griggio.

He continued: “We are in production 24 hours a day, seven days a week with 60 automated molding lines that produce 18 million pieces a day and 6 billion pieces a year. We’re a busy place! Our high level of experience and the use of the best technical solutions guarantees compliance with the maximum quality standard. Having all our facilities in Italy allows us to maintain these standards. Also, in our R&D labs, we carry out daily safety checks to maintain compliance with quality standards set by the world’s leading organizations.”

These high standards set SapiSelco products apart from the competition with cable ties that can withstand harsh conditions, including heat, cold, direct sun exposure, flame resistance, and harsh chemical environments. Some of the company’s cable ties are made with phosphorescent that can be used in places subject to blackouts. Others are color coded for identification requirements. The company even produces cable ties that use nylon materials so can be discovered by metal detectors.

These high standards set SapiSelco products apart from the competition with cable ties that can withstand harsh conditions, including heat, cold, direct sun exposure, flame resistance, and harsh chemical environments. Some of the company’s cable ties are made with phosphorescent that can be used in places subject to blackouts. Others are color coded for identification requirements. The company even produces cable ties that use nylon materials so can be discovered by metal detectors.

“Since 1950, we have been fully focused on developing the best cable tie on the market. We now see the market changing, not with regard to price, but in reliability and quality of products. Our goal is to enlarge our specialization and reach the highest level of automation in production for highest quality output. We want to enlarge our certification and standards to be able to work in every kind of market and increase our presence abroad. That’s one of the reasons we’re now working with AutomationDirect. We are committed to remaining the recognized leader as the Italian specialist of cable tie production,” explained Griggio.

Cable Ties Transformed into Art

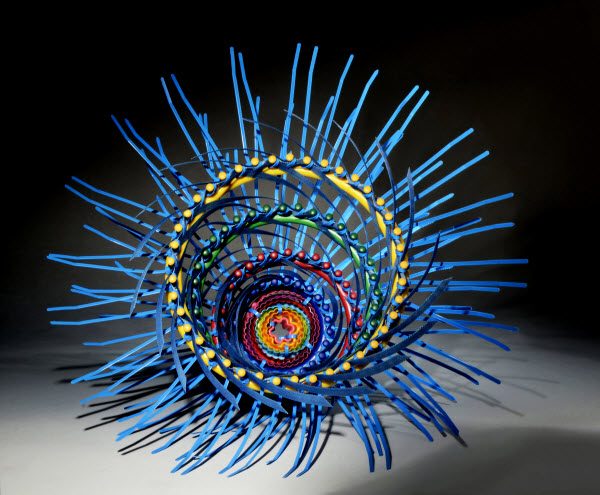

Although many companies support the arts, the Griggio family with SapiSelco have taken their love of art to a new level. Giacomo Griggio is the creative mind behind the ArtisTie program which blends two ideas – art and technical production – into one beautiful creation.

The SapiSelco company loves art, and with ArtisTie promotes a space dedicated to a world normally considered to be outside the realm of cable tie products. Started in 2014, ArtisTie is an innovative project that gives space to artists to produce original and unique works using Cable Tie Art & Design. The artists who participate are asked to look beyond a mere technical product to ‘find aspects that inspire real beauty.’

Griggio explains the ArtisTie program: “An object that to the untrained eye may look simple, but which actually hides extremely complex technical characteristics, capable of offering different possibilities for use in the widest variety of sectors, some truly unimaginable. Art is an unfettered world, free from conventions, and we have managed to listen to it and meet the needs of the artists we are in contact with. We have in this way started to conceive the tie as an artistic object, so much so that we decided to give it its own dedicated space. We strongly believe in ArtisTie and intend to develop it over time. Our desire is to turn this virtual space into a physical ArtisTie showroom inside our company, where we can show the works of our artists and highlight the passion that, for years, has driven us to dedicate ourselves totally to this product, culminating in this artistic celebration.”