PLCs are typically programmed with PC-based software, and selecting the right platform is critical to project success and ongoing operations.

Bill Dehner, technical marketing engineer at AutomationDirect, wrote an article for the February 2019 issue of NASA Tech Briefs titled Selecting a Software Programming Platform, here’s a summary.

Dehner says software development and testing is about half of the control system design and integration effort, so a programming platform that can ease and speed these activities is vital. It’s advantageous when the platform can be used to program an entire family of controllers as this allows the target controller to be selected after the programming is done, resulting in just the right controller selected for the application.

These PC-based platforms are typically used to program a family of target programmable logic controllers (PLCs), with both the PLC hardware and the programming software provided by the same vendor.

As automation applications vary widely, so does the amount of time required to program a PLC or similar device. For ease of use, the PC-based controller programming software platform should include ladder logic as one of its programming languages, he says.

Although several other programming languages are sometimes used, ladder logic is the best choice in many applications because it’s very orderly and similar to schematic wiring diagrams, making it simple to follow.

Comparing Programming Platforms

The features and functions of several programming platforms can be compared along with their accompanying PLC hardware targets, with users selecting the best combination of both. This is a better approach than evaluating the PLC family in isolation because picking the best PLC hardware won’t pay off if the programming software is too hard to use. Online training helps, Dehner points out:

Online training documentation and videos are becoming the norm, and should be embedded with the programming platform. These videos are often the quickest way to attain software fluency and execute successful projects.

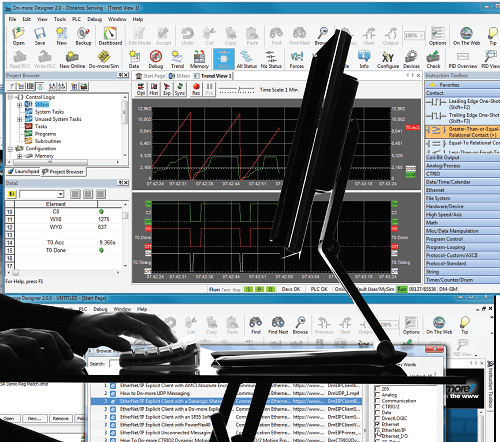

This Do-more Designer software programming platform from AutomationDirect supports multiple PLCs and includes built-in training videos.

This Do-more Designer software programming platform from AutomationDirect supports multiple PLCs and includes built-in training videos.

Software tech support is another consideration. With some software platforms, a yearly service fee costing thousands of dollars is required for anything but limited support, and sometimes an hourly rate for support is added. Other vendors, like AutomationDirect, offer free tech support, which can result in substantial savings over the lifecycle of the programming platform.

Data logging and remote access is becoming common today, and the software platform should provide methods to configure these functions, with no custom programming required.

A software platform that supports a wide range of PLCs, small to large, is important. With some research up front, it’s possible to find a programming platform that is easy to use, cost effective and acceptable to programmers.

To read more articles about PLCs, click here.

Originally Published: March 2019