By: Rin Irvin and Josh Waters

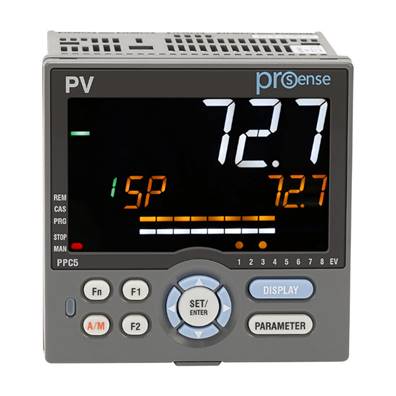

It’s an engineering truth that there’s no such thing as a perfect solution, just the best solution for the project at hand. This principle remains true for process control applications. PLCs are powerful and comprehensive control solutions, but not every industrial process needs that level of functionality. For every complex, highly synchronized process, there are dozens more standalone processes that only require monitoring of a single variable such as temperature, pressure, flow rate, etc. For these types of systems and machines, a single-loop process controller can provide a simpler, more compact, less expensive, and more easily integrated solution than a standard PLC (see Figure 1). Keep reading to discover how single-loop controllers can streamline your next project.

What are single-loop process controllers?

Single-loop process controllers are compact devices designed to monitor and control a single process variable. Logic built into the controller acts on a single input to generate multiple control and alarm outputs. Unlike PLCs, single-loop controllers do not require extensive programming and are easily configured using faceplate buttons or free PC software. The result is a solution that is fast and easy to integrate while minimizing the expertise needed to get the system up and running.

Within the class of single-loop process controllers, the levels of sophistication vary. Some offerings are purpose-built to control a specific characteristic, such as temperature. Others are more general process controllers equipped with logic that can be configured or customized to act on a variety of inputs.

Inputs

Single-loop controllers accept a variety of inputs such as thermocouples, resistance temperature detectors (RTDs), or analog current/voltage signals. These analog signals can be used to precisely monitor and control process variables such as pressure, pH, level, or flow rate.

Outputs

Single-loop controllers can support a variety of electrical outputs, including relays, voltage pulse, 4-20mA, 0-10 VDC, and input signal retransmission.

These outputs control devices like pumps, valves, or heaters. For example, voltage pulse is ideal for solid-state relays (SSRs), while analog output like 4-20 mA is best for driving power controllers or valves. Input signal retransmission can be used to send system data like process variables (PVs) or measured variables (MVs) to PLCs/data loggers.

Logic

Unlike PLCs, which can require extensive programming, single-loop controllers use built-in logic that is configured in a few steps, even PID algorithms can be easily setup with the built-in autotune feature to manage simple or advanced control loops.

Depending on the single-loop process controller, users may be able to choose from several different control modes, including PID, on/off, ramp/soak, or manual. These modes enable single-loop controllers to support a variety of applications.

Communications

Although single-loop controllers are designed for use in standalone equipment, many modern devices have built-in communications capabilities like Modbus RTU over RS-485 or even Modbus TCP and Modbus gateways via Ethernet (see Figure 2). This enables controllers to be daisy chained together to communicate with a PLC, HMI, or SCADA system.

Single-loop Controllers in Action

As a simple example, a single-loop temperature controller operated in PID mode could be used to maintain a constant fermentation temperature in a microbrewery. The devices can also make more complex applications simpler. A single-loop controller with ramp/soak mode provides a quick and easy solution for annealing. Rather than writing a program detailing each temperature change and hold in the process, a user could just configure the controller, either using the buttons on the faceplate or a PC application. The outputs control heating and cooling equipment and can include logic and alarming to prevent thermal runaway.

For some applications, it’s not even necessary to run the auto tune routine or select PID parameters. On/off control, which is nearly universal for single loop controllers, works great for many simple/slow applications.

Alternatively, single-loop controllers can be used as a group to support zone applications, such as in injection molding. One single-loop temperature controller could control the feed zone (rear zone), one could control the transition zone (middle zone), and a third could be used to control the metering zone (front zone). To support more zones, just add more controllers – this is where the reduced size, cost, and complexity come into play. Zone temperature control has a variety of use cases, from bakeries to kilns.

In another example, single-loop controllers are also very effective for monitoring and controlling tank levels. With a level sensor providing a 4-20-mA input signal, a controller could use an analog output to drive a valve actuator. Alternatively, it could control the speed of a pump by sending a control output to a variable frequency drive.

The Benefits of Single-Loop Process Controllers

We’ve already mentioned the more obvious advantages, including small size and low cost, but let’s take a closer look at some others.

Ease of Use

Installing a single-loop controller just involves connecting one input, one or more outputs, a power cable, and communications wiring, if using. Configure the device, run an autotune subroutine if required, typically using the buttons on the front face, and the process is ready to go.

In contrast, PLCs require significantly more set up and engineering, including wiring and programming, just to get started. More wiring increases cost, both in terms of capital outlay and also installation time. Less wiring decreases points of failure and reduces the chance of error.

While we’re on the topic of reducing errors, single-loop controllers are more standardized than PLCs. The emphasis on configuration rather than programming makes them inherently less subject to human error. True, they don’t offer as much flexibility as PLCs, but for the appropriate applications, this isn’t a concern. In addition, advanced single-loop process controllers offer a significant amount of freedom to configure units for different applications.

Because logic is built in, organizations don’t need as much expertise to build or integrate the equipment. Nonrecurring engineering hours for programming (and troubleshooting) are reduced, which speeds build out and reduces costs. Some of the built-in logic could be difficult or time consuming to implement via programming. Ramp/soak control, for example, would require stepping through logic in a PLC program. With a temperature controller, the steps are just configured using parameters.

Integrated solutions

Some entry-level PLCs are available at very low cost but be sure to compare apples to apples. Single-loop process controllers are integrated solutions. They already incorporate the displays, the input, the software, etc. A comparable low-cost PLC would still need an input card for a thermocouple, for example, as well as a panel meter or HMI to display the PV, MVs, or SPs that a single-loop controller would include out of the box.

Variety of Form Factors

A choice of form factors makes single-loop controllers easy to integrate into equipment. Users can choose between panel-mount devices and DIN-rail units designed to fit into a cabinet where space is limited. Panel-mounted devices are available in standard DIN form factors, with buttons for configuration/auto tuning and displays to show SPs and PVs. DIN-rail-mount units do not have faceplates with displays or buttons, and must be configured by PC software (see Figure 3).

Single-loop process controllers are designed for monitoring single variables in standalone systems or machines. They provide local control and monitoring, although many can communicate with a PLC for remote control or to export data.

For simple applications requiring the control of a single variable, single-loop controllers offer many advantages over PLCs. They’re integrated packages that require minimal effort to obtain maximum results. Many include built-in communications functionality. They don’t require advanced programming, just parameter configuration, saving time, lowering engineering costs, and reducing the possibility of error. Merely install, auto tune, and for most applications, the units are ready to go. Right size your engineering – consider whether a single-loop controller might be the best control solution for your process and your budget.

AutomationDirect offers two lines of single-loop controllers. Consider our SOLO product line of single-loop temperature controllers for standalone processes requiring tight thermal control. For processes with more sophisticated demands, our ProSense family of process controllers offers increased flexibility and capabilities.