A team of engineering students from Oklahoma State emailed Automation Direct last year with a disturbing problem: Fish were dying!

These engineering students had been contacted, in turn, by students in the nearby Culinary Arts program who run an aquaponics farm. Aquaponics combines aquaculture (raising fish and other marine life in tanks) with hydroponics (growing plants in a water-based medium). This technique fertilizes the plants with the nutrient-rich waste from the fish, while the plants cleanse the water of excess nitrates and ammonia which are harmful to the fish.

The aquaponics farm was experiencing issues with fluctuating PH levels, in particular. Long weekends and breaks between semesters posed challenges for their manual testing and maintenance programs. “This lab requires fairly close monitoring of water levels, pH, ammonia, temperature and nitrates,” said Celia Melson, Culinary Arts instructor. “If something in the system gets off, it can lead to unsafe levels for the fish, which then can lead to their death if not remedied, as well as the death of plants. If, for some reason, the system cannot be monitored regularly, there can be issues that cause a fish to die. If one fish dies, the ammonia levels can rise to unsafe levels causing further fish issues and deaths.”

The engineering students are part of the Instrumentation Engineering Technology capstone class, and they quickly realized there might be opportunity to automate the maintenance and monitoring of the entire system.

The student engineering team was led by Brandon Huizar, and included students Cole Crum, Dustin Martin and Jadarius Williams. This team worked together with the Culinary Arts students to develop a system that monitors the fish tank’s pH, temperature, water, and oxygen levels as well as the ambient air temp in the lab. They also included automation of the various pumps and grow light schedules to enhance the system even further.

“The students got real-world experience in building a project from the ground up. There is no better experience.” said Amanda Cullum, Instrumentation Engineering instructor. “This project incorporated the majority of the technologies taught in their core classes, which helps to show the students what they learn in the classroom they will use in the workforce.”

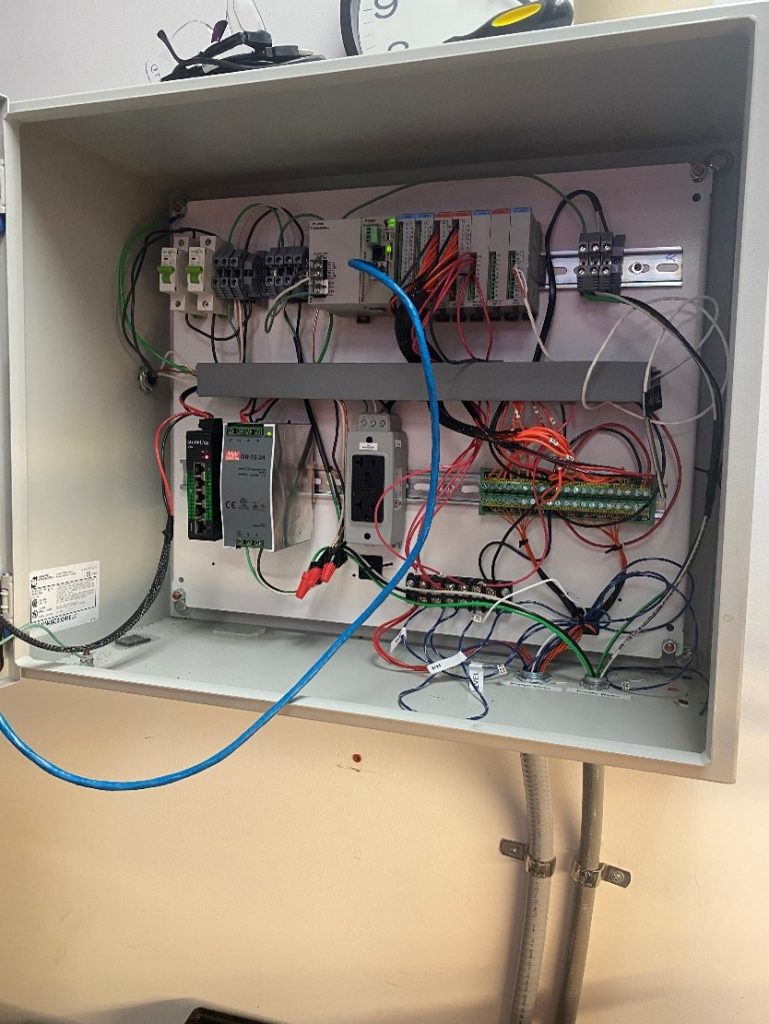

The team choose an AutomationDirect Productivity1000 PLC as the controller for the project. The PLC processes inputs from all the monitoring sensors, and controls four pumps that pump water from the fish tank to four separate hydroponics “grow stations”. Each grow station has a set of grow lamps which are also under PLC control.

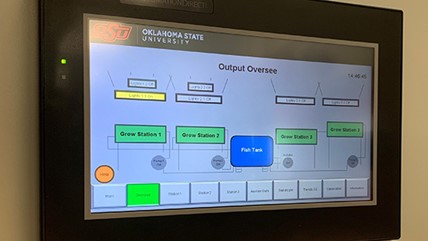

A C-more touch panel HMI was used to provide a visual user interface to the system. HMI screens were created to include a system overview, numerous drill-down screens to provide calibration for the analog devices, trending screens for oxygen and PH levels, and even a QR code screen that a user can use to access documentation of the system on a mobile device. A STRIDE 5-port industrial Ethernet switch was selected to interface the PLC to the HMI, and to put the system on the school’s internal network. The entire control system was housed in a Hammond Eclipse series wall-mount enclosure.

In addition to providing the local control and onscreen visuals for operators in the lab, the students are actively working to setup various alarm conditions that can automatically generate emails if certain parameters go outside the expected norms. So, now the fish (and plants) can effectively send an email when they need help, while they are still alive!

“This campus has so many great opportunities for students,” said Cullum. “Working with Culinary Arts on this project is going to open doors for other programs that might not have thought about working together. Instrumentation and Culinary Arts are two programs that I would have never thought could collaborate, but we worked great together to accomplish this goal.”

“Often, we teach very much in silos,” agreed Melson. “We are focused on our students and what they need to learn to prepare them for our industry. This was a great opportunity to collaborate and provide direct student benefits in multiple areas at once. The team that completed the work was outstanding, and I am super proud of these students. They did an outstanding job!”

More information about this project:

https://osuit.edu/news/instrumentation-engineering-aquaponics.php

More information about the IET program at OSU:

https://osuit.edu/sect/instrumentation/

More information about the Culinary Arts program at OSU:

https://osuit.edu/sash/culinary/