Surge suppression provisions are now mandated for many applications, and users are recognizing the value of protecting increasingly digital and connected systems from electrical disruptions.

By David Saenz, AutomationDirect

For many years, surge suppression protective devices may have seemed like an optional and supplementary choice, perhaps something consumers plugged their sensitive computers and TV equipment into for peace of mind. However, in an increasingly digital world, there are now greater regulatory requirements around providing surge protection in a variety of residential, commercial, and industrial applications. The proliferation of intelligent devices, EV charging stations, data centers, and countless other applications all require surge suppression for top performance.

Power surges can originate in many ways, and the apparent and hidden costs associated with these disruptions increase exponentially based on the degree of electronics and automation involved. For industrial operations, surge protection is about more than preventing electronics damage. New products and regulations are available to help designers create surge-resistant systems that maintain uptime, protect valuable data, and provide other safeguards.

Surge Sources and Hidden Costs

Electrical surges can originate externally to or internally at a site, although some estimates indicate that the majority (perhaps 80%) are attributable to internal sources. Some common causes are:

- External: Lightning strikes, utility and generator grid switching, or nearby faults.

- Internal: Motor starts/stops and variable frequency drive (VFD) inverter operation.

- Restoration: Surges instigated when a utility restores power after an outage, or a site engages backup power.

Surges take many forms in terms of how the voltage and current vary, and they frequently cause electronics and hardware damage. But there are also other hidden costs. Any disruptions leading to downtime stop production, and may waste product. Outages also create labor waste, both in terms of workers waiting for systems to come back online, and for technicians to troubleshoot and then restore service. In the worst case, a domino effect causes all these issues.

Expanding Surge Suppression Requirements and Technologies

In recognition of the growing importance for addressing surge suppression, industry standards and product technologies are both evolving. Some key standards include:

- UL 1449 “Standard for Surge Protective Devices (SPDs)”, now at edition 5 as of 2021.

- IEC/EN 61643 series, addressing SPDs for a variety of applications.

- IEE C62 series, addressing many surge protection topics.

- NFPA 70, the National Electrical Code (NEC), now has many sections related to surge protection.

The surge protection bar continues to rise. Some original requirements called for surge protection on “industrial machinery with safety interlock circuits” (which included a large number of installations), and today the requirements have extended to various types of dwellings. Surge protection techniques are applicable for main power distribution, and even for low-voltage signaling circuits, which may be susceptible to surges.

Industrial-grade SPDs are designed to detect and divert harmful overvoltage conditions, shunting the surge to ground before it can reach sensitive downstream electronics (Figure 1). Metal oxide varistors (MOVs) and gas discharge tubes (GDTs) are two fast-reacting technologies commonly used for handling and clamping excess voltages, and there are other hybrid designs as well. Some OEM equipment includes built-in SPD provisions, but power distribution systems of all types can require surge protection.

Unfortunately, SPD technologies tend to be sacrificial. Therefore, there are increasing requirements to provide indication and even signaling to prove that protection is active, and to let personnel know if a replacement is needed.

Implementing Surge Protection

SPDs are parameterized by characteristics such as the single surge current rating, nominal discharge current, short circuit current rating (SCCR), response time, nominal operating voltage, maximum continuous operating voltage (MCOV), and voltage protection level (let-through voltage). SPDs are usually available as parallel-connected devices, but they can also be connected in series. They may or may not require overcurrent protection, or compliance with the tap rule, depending on the installation.

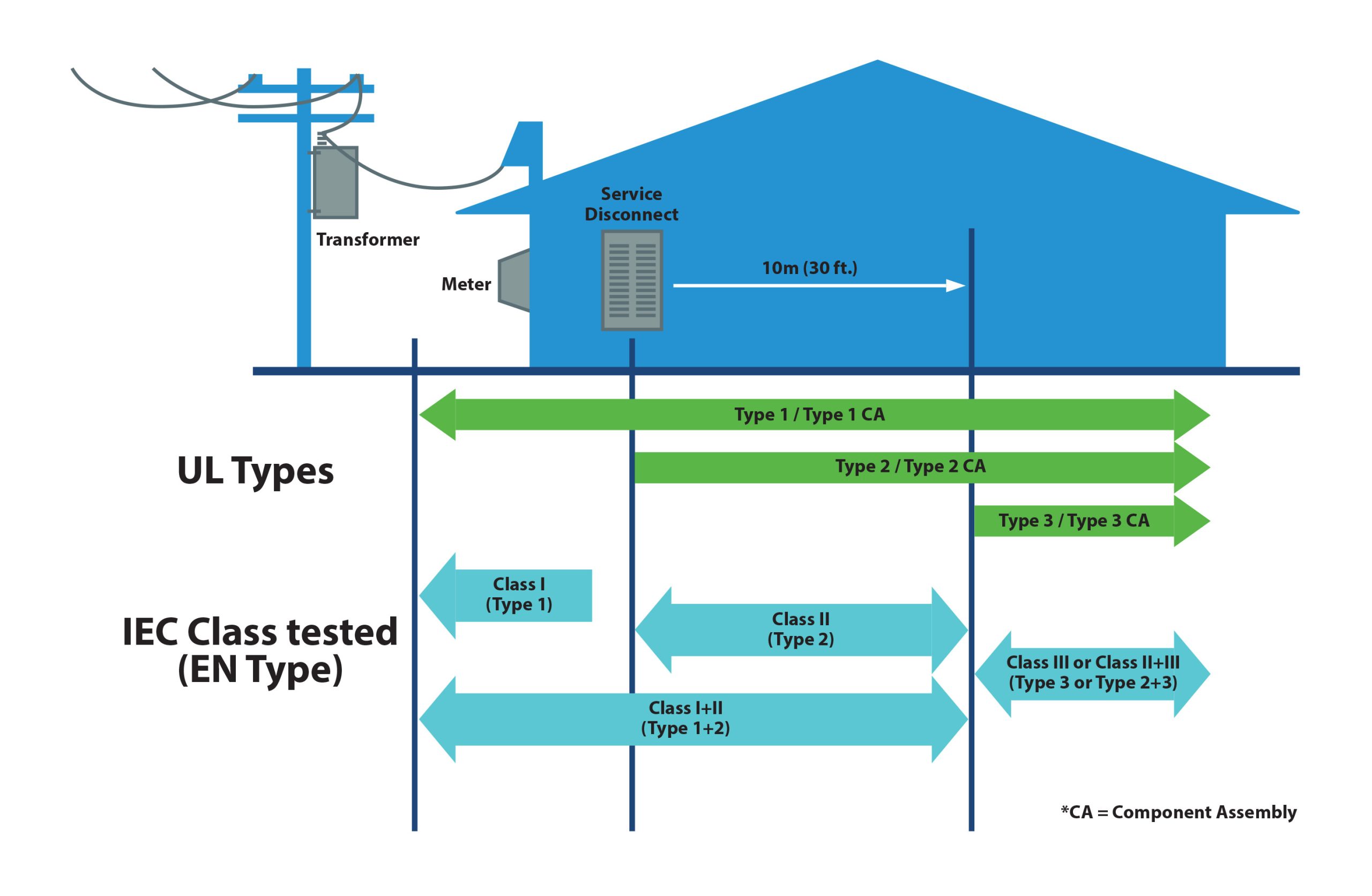

UL has defined several SPD categories (Figure 2):

- Type 1: Permanently connected SPDs intended for installation between the secondary of the service transformer and the line side of the service equipment overcurrent device, as well as the load side.

- Type 2: Permanently connected SPDs intended for installation on the load side of the service equipment overcurrent device.

- Type 3: Point of utilization SPDs, installed at least 10 meters from the service panel, usually at the point of use.

- Type 4 Component assemblies (CAs): Assembly of discrete components intended to be integrated into end-use products or larger SPD assemblies

- Type 5: Discrete components such as MOVs.

Figure 2: Several categories of surge protection devices are defined for use at various locations of the electrical distribution system within a facility.

While surge suppression may be mandated for new installations, it is also prudent to retrofit SPDs into existing systems. A variety of SPD form factors exist to support any type of installation:

- Open types, for panel or DIN rail mounting, with one or more circuits. Some types have plug-in protection modules for fast hot-swap replacements.

- Enclosed types, for external mounting near the connection point.

- Terminal block types, for high-density DIN rail mount, especially useful for data- and signal-level surge protection.

- Conduit-compatible types, made of stainless steel for installation right near a field device.

- Specialty configurations, designed for direct installation to the busbars of compatible panelboards.

Surge Protection is Fundamental

In the age of increasingly connected digital systems, and industrial internet of things (IIoT) deployments, surge protection is no longer just a “nice to have,” but a fundamental need or regulatory requirement. Industrial surge protection is more than an insurance policy—it is a performance strategy for safeguarding assets, uptime, and valuable data. Visit the AutomationDirect website to discover surge protection products for a wide range of applications.

David Saenz is a product engineer at AutomationDirect. He joined Automation Direct in 2024, and holds a BSEE degree from the Georgia Institute of Technology. Before joining the company, David Saenz spent 10 years supporting a medical device manufacturing facility as a controls and electrical engineer. He previously worked as an I&C engineer supporting civilian nuclear power generation engineering projects.