Embedding videos is just one way AutomationDirect’s free Do-more® Designer Software does more. One of the big steps for an automation professional is understanding how to control a machine, and a huge part of that is becoming proficient with development environment for the PLC.

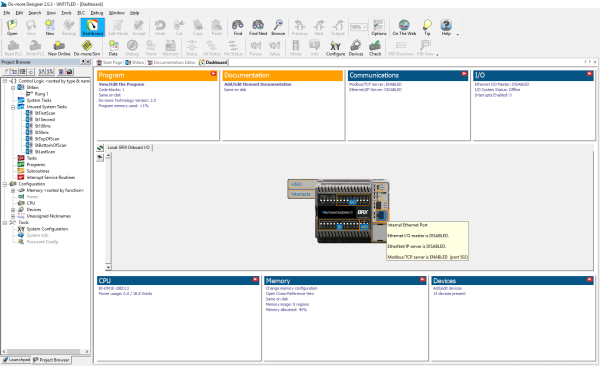

Whether a new or seasoned programmer, what’s needed are the easy to use yet powerful development capabilities provided by the Do-more Designer Software. A point and click Dashboard to simplify configuration and access to the program, documentation, communications, I/O, CPU, memory and devices is just the beginning. There are also configurable data views and trend views, along with code and PID process simulators. There are also system logs and monitoring tools, cross references and layered security features to understand and configure.

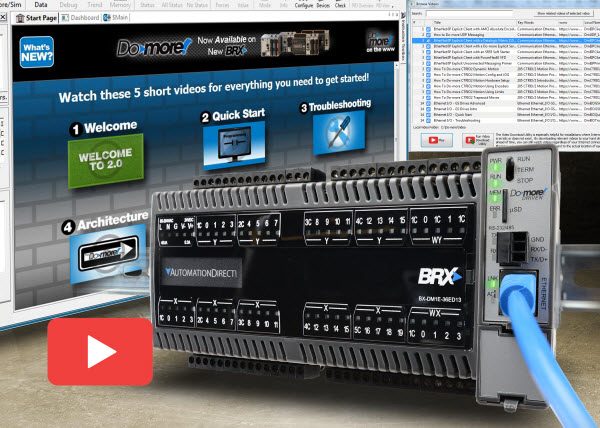

Learning how to use a powerful development environment for PLCs, such as Do-more Designer Software, may seem overwhelming. Fortunately, there are videos to illustrate. When the Do-more Designer Software is initially opened, the Start Page has five short videos depicting everything you need to get started. This includes a Welcome, Quick Start, Troubleshooting, Architecture and Helpful Hints video.

If more training and information is needed, a video search and download utility provides quick access to well over 100 videos for help with system, program, instruction, motion, communication, HMI, device and other areas of interest. An Internet connection is all that’s needed to access the videos, or the videos can be downloaded for times when Internet access is not available.

Quick Start

So you open the box, power up your new BRX PLC, and download the latest version of Do-more Designer Software. Now what? Watch the Quick Start – Connect, Enter, and Download a Simple Program video.

[videoembed type=”youtube” align=”aligncenter” width=”500″ height=”300″ url=”https://youtu.be/w7Dh2whozRs” id=”0″]

Plug the USB cable into a Do-more PLC and connect it to a computer. The video shows it is not much different than inserting flash drive into a USB port on a PC. It automatically connects to a previous project, or a new offline or online PLC project can be created.

If creating a new online PLC project, click ADD and select the one and only PLC connected, and give the link a name. The video then leads you through the steps required for creating a new on-line project. The Dashboard that appears within the software, including an image of the PLC, makes it easy to configure all parts of the controller.

There are even play or run buttons for videos embedded in the Dashboard. Just click on play and a list of videos appears.

The Quick Start video also provides a quick example of writing a program and accepting it so it is ready to be written to the PLC. Do-more Designer checks the program. The user then saves it, writes it to the PLC, and switches to RUN mode. The program could also be downloaded to the built-in simulator to test it without hardware, a very useful feature.

Troubleshooting the PLC Hardware and Program

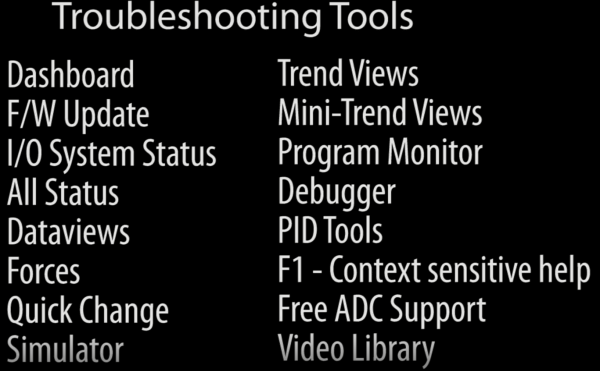

A Troubleshooting icon is also available from the Start Page in Designer. Click on it and watch the video describing the many Do-more Designer tools available to troubleshoot and debug your PLC programs.

The troubleshooting video provides several examples showing how to find problems and fix them quickly. It helps make sense of the large amount of information displayed in the Dashboard. One example shows that if there is a warning or something is out of place, just click on the problem, within the Dashboard, and the proper dialog opens to help solve the issue.

The video also talks about how to use Dataviews to quickly see what’s happening in the program. Program it to just see what you want without having to open the whole data table and search for a particular piece of data. The list of tools is impressive, and tools not covered in the troubleshooting video are covered in other videos, which can be found using the video search and download utility accessed on the Start Page.

System Architecture

The Architecture icon on the Start Page opens another important video to help with understanding of three key things about the Do-more Designer architecture: devices, memory and system configuration.

[videoembed type=”youtube” align=”aligncenter” width=”500″ height=”300″ url=”https://youtu.be/JQXUDph1Jic” id=”0″]

Do-more is device centric. The device, a software interface to your program that controls the hardware, is similar to a printer driver. Configure the device and it talks to the hardware. The memory is typed, meaning a Do-more knows what each memory location’s purpose is within the program.

Much of this code is created automatically when a device is configured, such as a high-speed counter input module. System configuration is a top-down process to configure and modify the hardware, devices, servers and memory usage. System configuration should be done in this order (CPU, I/O, module, device, I/O mapping and memory configuration), because each item in the configuration can affect an item below it in the hierarchy.

Helpful Hints

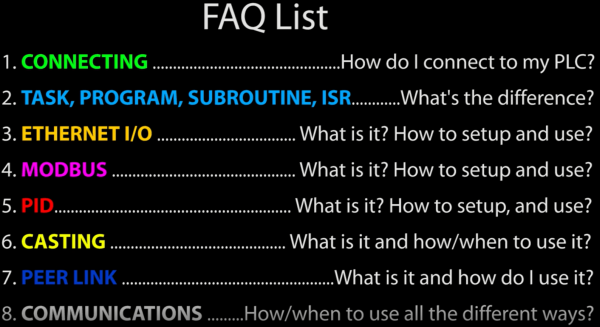

A final video icon on the Start Page is Helpful Hints. This video includes a list of the most common questions AutomationDirect’s support team receives related to a Do-more PLC. It shares the answers to these eight questions.

If after review of the many videos and extensive help files you still need help with Do-more Designer, don’t worry, it’s readily available via phone. Just contact AutomationDirect’s free award-winning support team during regular business hours, and they will be happy to help you spend less and do more with AutomationDirect.

To learn more about programmable control, click here.