Jim Krebs, technical marketing engineer at AutomationDirect, wrote an article in Processing magazine’s July 2018 issue titled Specifying Thermal Management Systems for Control Enclosures

Most automation and electrical devices must be housed in a control enclosure when used in industrial environments. This includes controllers, drives, power supplies, disconnects, fuses, terminals, relays, contactors and more. Krebs says changing temperatures in the plant or outside may demand use of both cooling and heating to maintain an optimal temperature.

Control of the temperature can eliminate the risk of condensation forming inside the enclosure, and eliminate overheating or freezing of the electrical devices. Different types of thermal management systems are used to control the temperature and other conditions inside control enclosures.

Krebs described how to specify these systems including venting devices, air conditioners, vortex coolers, heat exchangers and heaters.

Optimal Enclosure Temperature

Heat can be transferred into or out of an enclosure to control the internal temperature using conduction, convection and/or radiation. Conduction is heat flow through the enclosure wall or other solid materials. Convection is heat flow through a moving fluid or gas, or a moving fluid to the surface of a solid. Radiation is the transfer of thermal energy using electrical energy such as a strip heater. Heaters are not used very often, Krebs notes:

Since most electronic components perform better and last longer when operated at lower temperatures, heaters are not often used to keep internal components warm unless installed in areas where ambient temperatures dip well below freezing. In this case, heating is needed to stay within the operating range of the internal electrical components.

A Cool Control Enclosure

The need to cool a control enclosure is common because natural conduction from the exterior is often not sufficient to keep the internal temperature within an acceptable range. Too much heat reduces the operating life of electronic hardware such as controllers, drives, computers and displays. Excess heat can also require derating of power supplies, change circuit protection performance or trip an overload.

There are internal and external factors affecting an enclosure heat load. Ambient temperature has a large effect as heat flows from a higher temperature to a lower temperature. High ambient temperatures often create the need to cool an enclosure. An enclosure can also seal in heat produced internally if it is not properly vented. Other cooling methods can be used if venting to ambient while keeping contaminants out is not possible, or if venting is not sufficient.

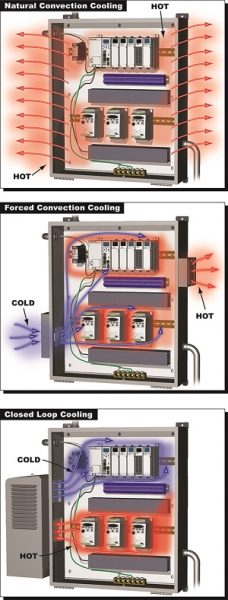

Common enclosure cooling methods include natural convection, forced convection and closed-loop. Vortex cooling, which generates a stream of cold air using compressed air, is another enclosure cooling method.

Common enclosure cooling methods include natural convection, forced convection and closed-loop.

Natural and Forced Convection

Natural convection, caused by hot air rising, can circulate the air in a control enclosure and keep it cool. Forced convection adds a fan to improve heat-transfer rates. Krebs says if minimal cooling is needed, natural convection using two grills or louver plates with filters is a common solution.

With proper installation, hot air exits the top of the enclosure due to convection, drawing in cool air at the bottom of the enclosure. In applications where the environmental rating needs to be maintained and the enclosure needs to be sealed, breather vents and breather drains can be used.

Forced convection provides better heat removal by using a fan to provide a constant air flow through the enclosure, notes Krebs:

Typically, a fan and filter are mounted low in the enclosure to force moderately cool ambient air into the enclosure. An exhaust grill and filter installed high in the enclosure allows the hot air to be forced out. This forced convection can protect devices from overheating and eliminate localized heat pockets.

Common enclosure cooling methods include natural convection, forced convection and closed-loop.

Natural and forced air convection cooling does not always get the job done, and in these situations closed-loop cooling is required.

A Closed Cooling Loop

Reasons for using closed-loop cooling in control enclosures include:

- High ambient temperatures

- Internal components generating excessive heat

- Harsh environments

- Washdown areas

- Heavy dust and debris

- Airborne corrosive or chemicals vapors

Many closed-loop cooling options maintain the enclosure protection rating, including air-to-air heat exchangers and air conditioners. Krebs says air conditioning is the most common method of cooling due to its high capacity.

An air conditioner provides more cooling capacity due to the addition of a refrigerant, an evaporator and a condenser. Although the compressor uses much more electrical energy than a fan or heat exchanger, proper use of enclosure thermal management controls and high-efficiency compressors reduce these costs.

Basics of Sizing Cooling Solutions

In addition to choosing the appropriate cooling method, the size/capacity of the cooling device must be calculated.

Stratus air conditioners from AutomationDirect maintain a set temperature inside an enclosure using a closed-loop method, protecting devices from overheating while ensuring a contaminant-free environment.

Enclosure Fan Sizing: To calculate the minimum fan cubic feet per minute (CFM) for a forced-air cooling solution, determine the amount of heat to be removed (watts) and the maximum temperature differential (ΔT).

Air Conditioner or Vortex Cooler Sizing: When calculating proper unit size, worst-case conditions should be used, which eliminates the need to oversize. Two key factors in the cooling calculation are internal heat load and heat load transfer.

In the article, Krebs describes how to make calculations for internal heat load, heat load transfer and cooling capacity for an enclosure, but cautions:

Be sure to understand whether the enclosure needs to be kept cool, warm or both. Once the cooling and heating system needs and methods are defined for an application, the solution must be properly sized and then the proper system selected.

For more articles on enclosures, click here.