Smart vision sensors incorporate on-board machine learning, empowering users to deploy them in common applications, without the cost and complexity of traditional products.

Common photoelectric (PE) sensors are the most basic type of “vision” device, but traditionally it has required much more advanced technology to capture and analyze actual images for advanced detection. In an article written by AutomationDirect’s Kevin Kakascik for Industrial Equipment News and posted in January 2023, Kevin explains how the latest intelligent and compact visions sensors are bringing essential vision-sensing technology to applications of all sizes. Following is a summary of the online article, which is titled Improved Vision Option for Smart Manufacturing .

Fundamental Vision

A full-blown vision system uses specialized cameras and higher-level computing resources, which are costly to procure, install, and configure. There are many applications that would benefit from vision sensing but simply can’t support these types of complex systems.

To address this and related issues, AutomationDirect now offers Datalogic Smart-VS series vision sensors. These all-in-one devices include embedded artificial intelligence technology to capture and process images right on-board, while being cost-effective and easy to configure. Key features of these smart vision sensors are:

- A compact form factor

- IP65/IP67 environmental protection

- 24VDC operation, with NPN and PNE outputs for “data valid,” “good,” and “no good”

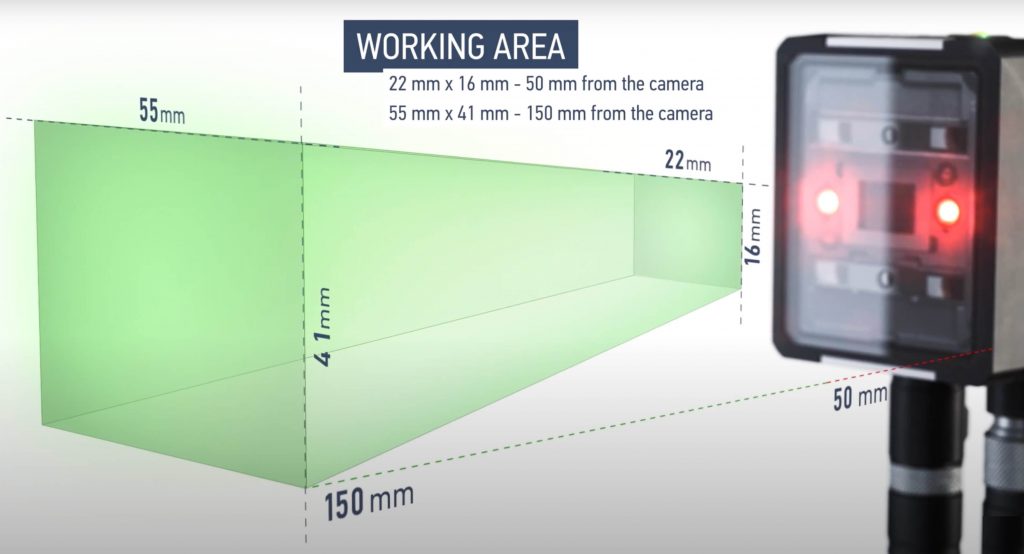

- Generous “working area” with a 50mm to 150mm depth of field and a 19-degree viewing angle

- On-board polarized white light sources

Vision Made Easy

While these smart vision sensors can’t read and interpret barcodes or QR codes, they can provide pass/fail indication for common detection applications, like:

- Label applied, or missing

- Cap installed and aligned, or not

- Product color correct, or off specification

- Fill level proper, or not

- Part orientation acceptable for pick-and-place, or not

The Datalogic Smart-VS can be configured quickly using a button that is on-board the device to perform a “teach-in” procedure for training up to four “good/pass” and four “no-good/fail” images. Four “jobs” can be configured, so the sensor can be used in multiple roles, and an intuitive web server graphical user interface is included, with Ethernet connectivity from the interface to the device.

Machine vision is a powerful automation tool, but until now has been specialized and expensive.

Modern smart vision sensors harness the power of machine learning to deliver many of the benefits found in much more complex and expensive vision systems, with nearly the ease of setting up a simple photoelectric device.

Visit the AutomationDirect website to find out how you can incorporate practical vision sensing into your applications, at a fraction of the cost and complexity of traditional large camera array systems.