Designers need familiarity with the variety of solenoid technologies used to upgrade equipment for remote operation and automation.

Kevin Kakascik, Technical Marketing Engineer, and Pat Philips, Fluid Power Product Manager, both with AutomationDirect, wrote an article for the January 2021 issue of Design World. The article is titled Upgrading Equipment with Solenoids, and discusses solenoid valve technologies, and shows how these can be applied for machine automation. Here’s a summary, click on the link above for the full text.

Designers often employ pneumatic components to create motion and force for equipment operation. Sometimes these systems are manually handled by operators. However, for any type of remote or automated operation, usually in conjunction with hardwiring or programmable logic controllers (PLCs), it becomes necessary to use solenoids of some sort to interface the automation with the pneumatics.

Upgrading Manual to Automatic

Valves are used to control the flow of liquids or gasses. They may directly control product flows in a process, or they may be configured to control powerful physical actions such as moving an actuator.

Simple design may use valves with manual controls like pushbuttons or levers, but for best efficiency, it is usually desirable to automate the function, typically with solenoid valves.

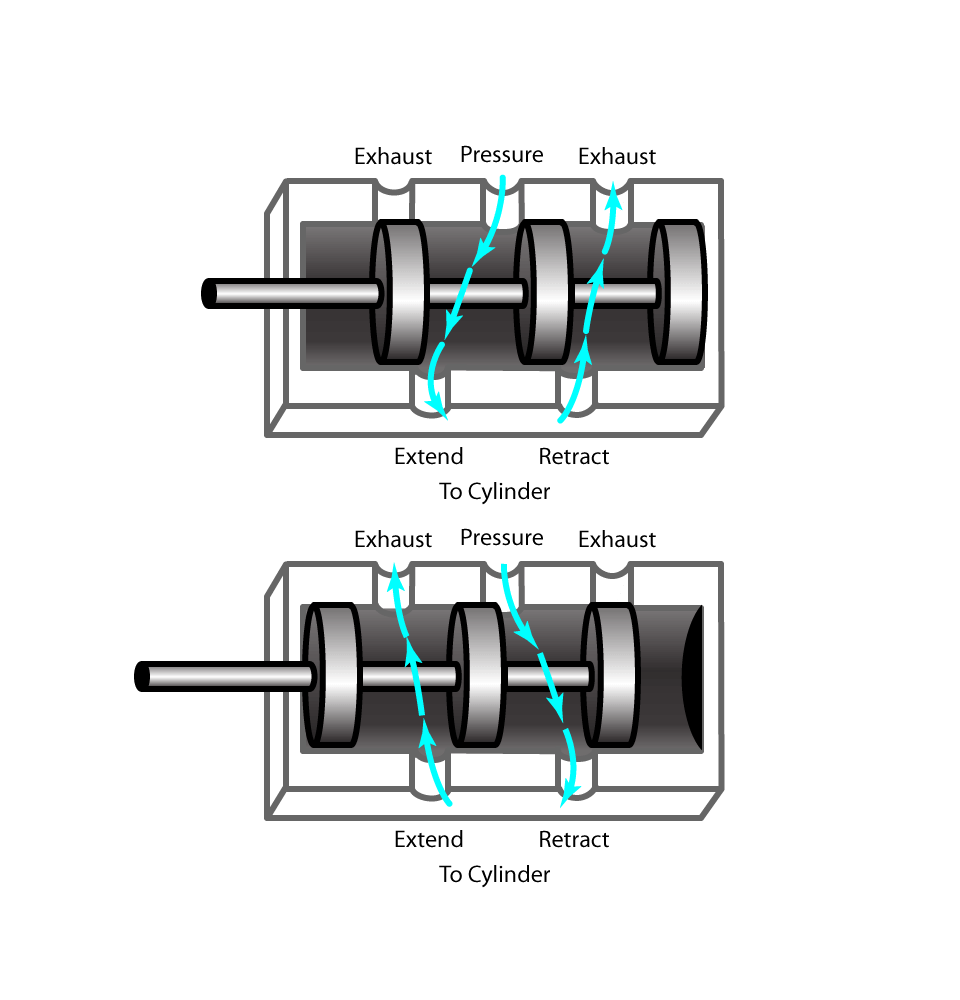

An electric solenoid consists of a wire coil arranged around a movable central poppet, plunger, or spool element. It enables an electrical current to create a low force linear motion controlling physical flow. A solenoid-operated valve effectively acts as an amplifier, converting a small electrical signal into a comparatively large physical force.

A range of sizes is possible, as electromagnetics can be quite powerful. A solenoid valve can be:

- Direct-acting for process valves of perhaps 0.75-in diameter or smaller

- Incorporated in solenoid-operated valves, which are larger but usually slower

- Integrated in an actuator to operate a much larger mechanical valve

In addition, smaller solenoids with minimal footprints and a low power draw are sometimes called “pilot valves” when they are arranged to operate larger physical valves. Their form factors can be standalone, stackable, or a modular type with a common manifold. The latter two styles simplify plumbing significantly. Many solenoids are designed for mounting in control panels, but some can be mounted in open areas, even where there are washdowns.

Know the Details

Designers must consider the operating fluid pressure and flow characteristics to operate target equipment with the right force and speed. Other details include:

- Port sizes

- Normally closed (NC) or normally open (NO) function

- Required number of positions

- Whether the solenoid is single-acting (with a spring return) or double-acting

Solenoids Get Smarter

Basic solenoids are wired to circuits or PLCs, but newer intelligent solenoid valve manifolds are capable of communicating with controllers using industrial fieldbus or Ethernet protocols like serial Modbus RTU or EtherNet/IP. These smart manifolds reduce wiring, increase the information flow between controller and solenoid, and make it possible to merge other input/output points with the manifold.

Moving to Solenoids

Making the move to upgrade manual operations to automatic functionality using solenoids yields better safety, improved production, and minimized downtime. Designers have many choices and can work with a comprehensive supplier like AutomationDirect to find the best options.

Check out more articles about solenoids and pneumatics here.