Electrical actuators are an efficient and accurate way to automate linear motion on machinery and equipment.

Automated machinery and equipment frequently require linear physical movement. Sometimes the mechanisms most move a product-holding tray into position, while other times the movement is for performing a manufacturing function, like drilling, inserting, gluing, or taping parts.

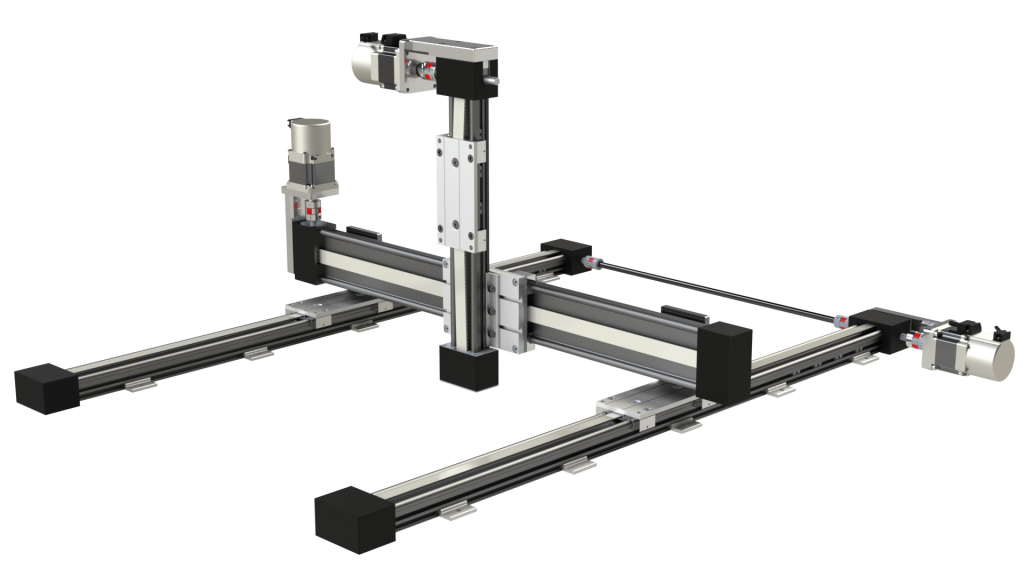

The motion can be in a single “X” axis, or it can be combined into multi-axis “X-Y” or even “X-Y-Z” gantry configurations. Depending on the application, users need to balance the need for parameters, such as:

- The load, and how much force is needed to move it

- Overall travel distance

- Whether intermediate stops or positioning are needed

- Travel speed

- Accuracy

AutomationDirect offers a variety of linear motion slides and actuators, and stepper motor linear actuators, so designers can find just the right fit for their applications. Following are some basics that OEM, systems integrator (SI), and other design personnel should understand about how and when to implement electrical actuators.

Making A Move

Two basic motions which can be created on equipment are rotational and linear. The typical motive forces involved are electrical, pneumatic, and hydraulic. Electrically-driven systems are generally accurate and efficient, and they can provide sufficient power in many applications. Pneumatics are compact, inexpensive, and powerful—but they can be loud. Hydraulics can achieve greater forces than any other motive technology, but they are relatively expensive and typically require frequent maintenance.

For rotational motion, it is most common to consider of electrical motors—such as AC, DC, servo, or stepper—but there are also actuators to convert pneumatic or hydraulic energy into rotational motion.

For linear motion, designers often specify pneumatic or hydraulic cylinders. However, there is another option for converting electrically-driven rotational motion to linear motion, the linear actuator.

Linear Actuators

Linear actuators are mechanical devices, usually powered by a rotational motion source like some form of electrical motor, to create linear motion. There are three major types of linear actuators:

- Ball screw driven: Utilize ball bearings that are continuously circulated in between the ball nut and the shaft. They are suitable for both light and heavy loads, and they provide high-performance, even at fast speeds and duty cycles.

- Lead screw driven: Use a threaded shaft with a simple nut. They can also be used for light or heavy loads and are a lower-cost option than ball screw driven.

- Belt driven: Consist of a toothed belt mounted between two pulleys to provide simple and dependable motion, and can operate over longer distances than the other two types.

Designers can arrange linear actuators to drive equipment and mechanisms. The driven components may move on wheels, rails, or other types of undriven linear slides to provide low-friction support along the length of travel.

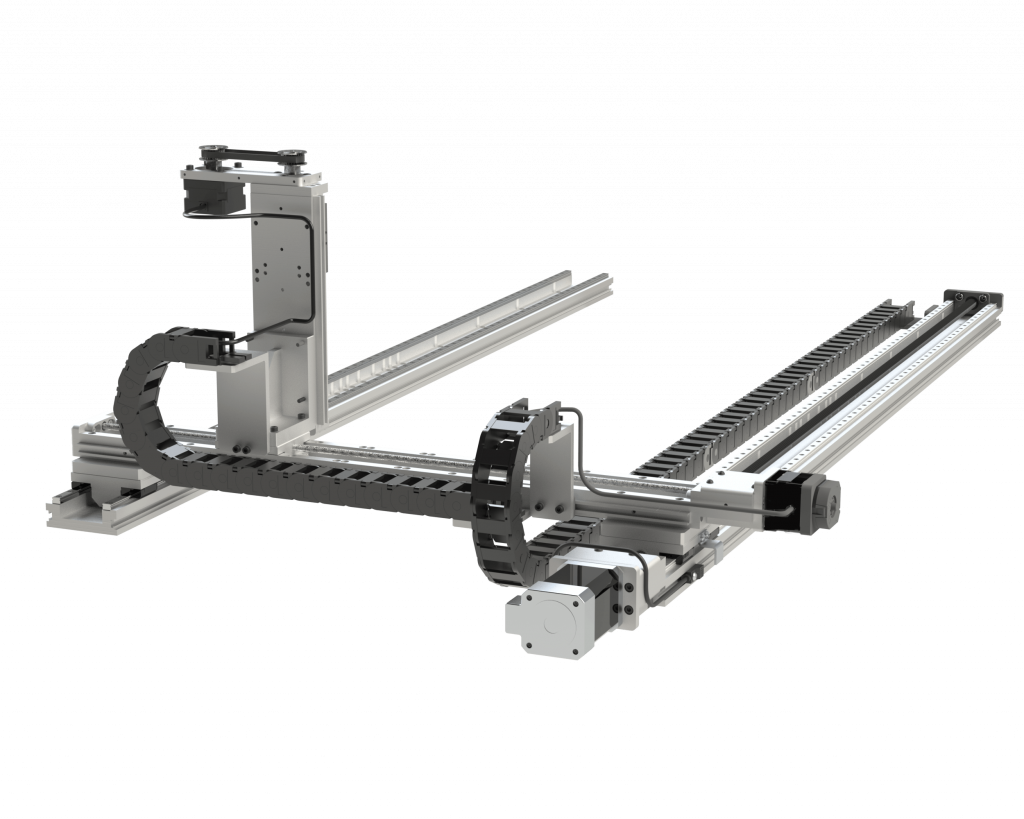

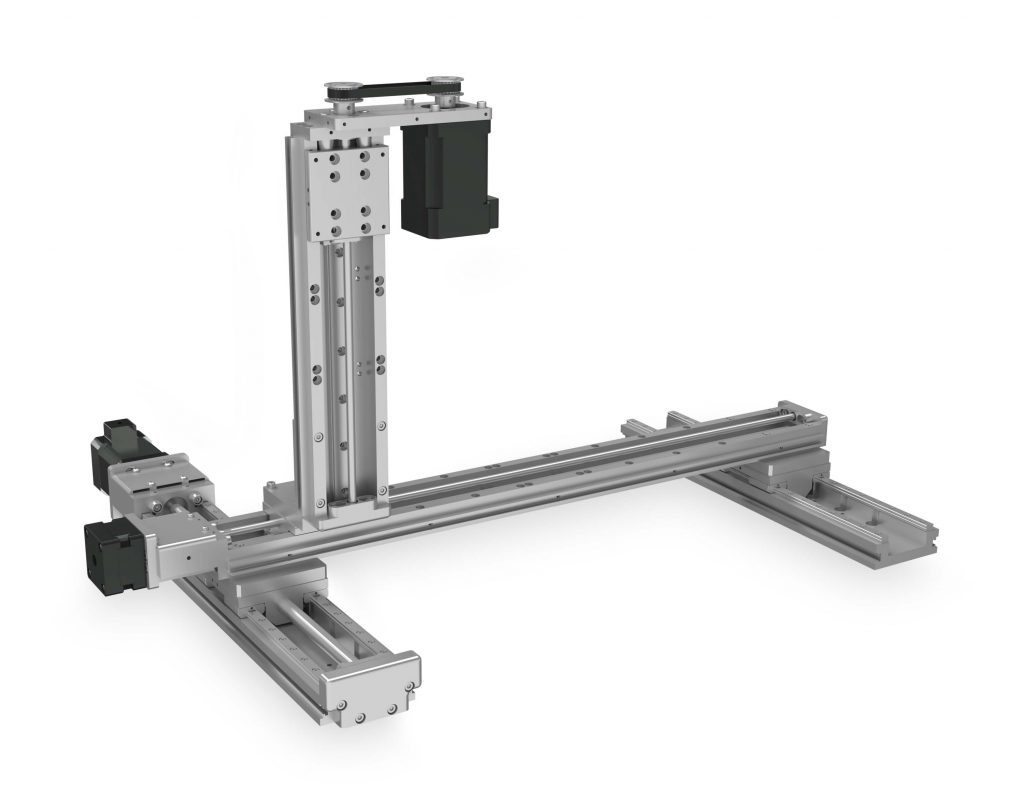

AutomationDirect stocks a wide array of these devices. The actuators are available with couplings and hardware to mount small NEMA frame stepper and SureServo motors as needed, with options to attach multiple units to create motion in two or three axes. AutomationDirect also provides many types of sensors, wiring, and more to help users create a complete solution.

Complete multi-axis motion solutions with linear actuators and slides

Another option is to use Sure Step Stepper Motor Linear Actuators, available in NEMA 17 or NEMA 23 motor frame sizes, with stainless-steel lead screws. These all-in-one actuators can be combined with undriven linear slides or shafts to create simple and economical linear motion solutions.

Selecting the Electrical Actuator

Electrical actuators are an efficient, accurate, and powerful method for providing linear motion on all types of equipment. AutomationDirect provides a wide array of products, options, and accessories, so users can create comprehensive solutions. Check out the AutomationDirect motion control website information, where you can find full specifications, drawings/documents, and videos.