Pilot devices are essential operator interface components for most automated equipment and processes.

As the industrial age dawned, machinery and equipment were controlled manually by operators pulling levers, turning hand cranks, and making similar actions and adjustments as they saw fit. Industry 1.0 was powered by water and steam, 2.0 relied on electricity and added hardwired controls, while 3.0 introduced digital-based automation. However, Industry 2.0 and onward has required updated forms of operator interface (OI), beyond basic mechanical interactions.

Modern OI elements must accept control inputs from operators and provide them with clear information and feedback about the equipment. Because users may spend significant time at the OI, these components must be easy to use, yet durable enough to withstand tough environments. For electrically- and digitally-controlled systems, the answer has long been pushbuttons, selector switches, indicator lights, and similar components—collectively called electro-mechanical pilot devices. While many modern systems have evolved to use digital/touchscreen operator interface terminals (OITs) and human-machine interfaces (HMIs), there remains a solid need for electro-mechanical pilot devices.

Pilot Device Basics

Industrial-grade pushbuttons and similar OI components are usually installed in the front panel/face of control panels, consoles, pendants and similar locations. Sometimes they are available in pre-configured enclosures for wall-, stanchion-, or pendant-mount applications, and there are some specialty options, such as foot switches. They are commercial off-the-shelf (COTS) components in standardized form factors, providing designers with many options for flexible implementations.

Panel-mount components are generally designed to fit into standard-size holes that are drilled or punched with a 16mm, 20mm, or 30mm size, although other sizes are possible. Most of these devices have a round appearance, but they can also look square or rectangular from the front. Sometimes the holes and devices are keyed with a small notch to prevent the device from rotating.

Designers may use colored pilot devices to help convey their functions to users, but best practice is to also include nameplates or engravings describing the function.

Physical Considerations

Designers must evaluate the following things when they select pilot devices:

- Environmental rating: Pilot devices are designed to be electrically touch-safe from the front, but they also need to resist any expected moisture, dirt, or other expected contaminants, while maintaining the integrity and rating of the enclosure where they are installed. Therefore, designers should evaluate and select an ingress protection rating meeting or exceeding the application needs. Common ratings include NEMA (1, 2, 3, 3R, 4, 4X, 12, 13), and/or IP65, IP66, IP67, or IP69K.

Devices are also available for use in hazardous locations, with ratings such as:- Class I, Div. 1 & 2, Groups C, D

- Class II Div. 1 & 2, Groups E, F, G

- Class III

- NEMA 3, 7 (C, D), 9 (E, F, G)

- Class1, Zones 1 & 2, Groups IIB, IIA

- Electrical characteristics: Pilot device electrical ratings for voltage and current must meet design requirements. Also, specifiers of industrial applications will look for devices that meet UL 508 or have other needed approvals. Many devices have screw terminals for wires, but push-in connections are sometimes available.

- Durability: Pilot devices often have both mechanical and electrical durability ratings, expressed as the number of operations they are expected or tested to endure. Temperature and vibration specifications are also provided by product suppliers to help specifiers identify components that meet the need.

Functionality

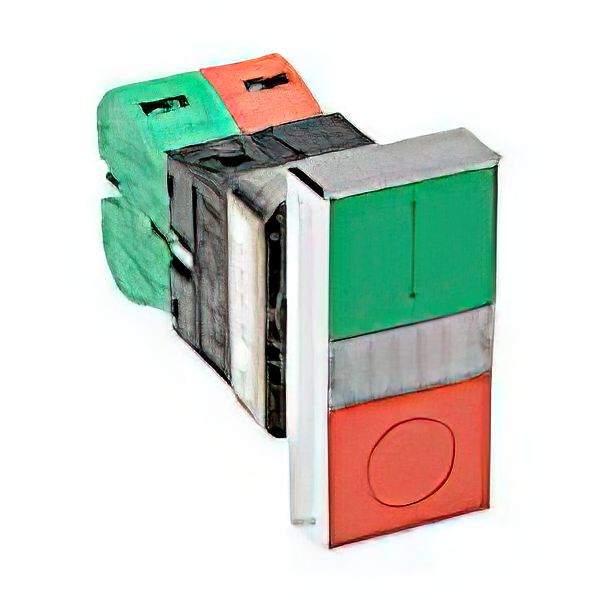

Some pilot device components are complete all-in-one designs. In other cases, the device consists of some combination of a front button/handle/lens, a functional operator, and electrical contact blocks. This provides designers with the option to change the color and look of the operator-facing element, the operation type, and the electrical function as needed from a range of COTS products and accessories.

Here are some of the most common pilot device categories:

- Pushbuttons: Common uses are for operators to trigger start/stop/jog functions. They may also include lighted indication. Two major actions available:

- Momentary

- Maintained (push on/push off, or push/pull)

Emergency stop (e-stop) pushbuttons : E-stops are a special category of pushbuttons, used to provide one-push action so users can quickly stop machinery or systems in the event of a problem. Buttons have large mushroom heads so the are easily actuated, and they usually require a pull or twist to reset.

Indicating lights: These components provide one or more lighted segments, with many colors and variations available. Some have a push-to-test functionality, and are therefore basically a lighted pushbutton. Traditional versions used incandescent bulbs, but today lighting is more commonly performed with bright and long-lasting LED bulbs.

Selector switches: Selector switches are convenient when two or more control states are needed. Models are available in a variety of colors and operator options, including key-operated, knob or lever; maintained or spring-return action; non-illuminated or illuminated, and others. Common actions are 2- and 3-position, sometimes with springs to return the device to a defined state when released.

Joysticks: Joystick switches are ideal when the control action may be more easily understood by the physical position of the operator. Models are available with a variety of operator options, including momentary or maintained action, and 2- or 4-position.

Potentiometers: Potentiometers create a variable output based on knob position. Models include 5 Kohm or 10 Kohm resistance circuits with a rheostat-style output and knob operator.

Capacitive switches: Capacitive switches use electronics instead of electro-mechanical functionality. They detect when a hand or body part is near the device’s surface. They may have a robust IP69K design suitable for harsh environments and are available in a variety of styles and mounting options, and they can also be very low profile. Hygienic models are EHEDG-certified for Food and Beverage applications.

Signaling devices: Signaling devices provide visual, audible, or audible-visual alarms and status notifications for industrial and commercial processes. These devices include beacons, LED signal columns, buzzers, horns, and visual-audible beacons in various sizes, mounting styles, lighting effects, and sound patterns.

Specialty safety: Other pilot devices are specialized to provide enhanced operator safety:

Cable-pull safety switches: These switches connect to a pull cable arranged over the length of conveyors or other machinery, allowing an operator to initiate an e-stop from any point along the installed cable length.

Foot switches: Foot switches are commonly used for applications where hands-free operation is required. Electric and pneumatic manual valve models are available, in a choice of operating actions and physical configurations.

Pneumatic switches: While this article is focused on electrical-based pilot devices, some pushbuttons and switches are available in pneumatic styles for use with pneumatic equipment where electrical solenoids are not desired or needed.