What is a Pilot Device?

“Pilot devices” is an industry term given to products such as pushbuttons, indicating lights, selector switches and various types of switches and visual and/or audible signaling devices. All these devices are used for a system, control panel or as an integral part of most automated processes to provide control and condition monitoring of all types of equipment, processes and machinery.

Today’s pilot devices include old school devices as simple as a momentary pushbutton that will momentarily activate a device to sophisticated IP69K-rated pushbuttons which are designed to prevent cross-contamination and withstand rigorous cleaning procedures like those required for food, pharmaceutical and medical applications.

These devices can also be used to improve safety for workers and equipment. Emergency pushbuttons are extensively used to completely disable a machine, system or process in the event of an emergency by simply pushing the button. Indicators can provide local or remote indication of a hazard, warning, or unsafe condition anywhere in a facility. Selector switches allow the operator to set a machine or process to a STOP condition or might have a key to lock out the switch and ensure that only the key holder can activate the switch, thus preventing accidental operation that may cause harm to the operator.

Pilot devices can be broken down into three main categories; pushbuttons, switches and indicators. We will take a quick look at these three categories below and provide a brief description of the types and uses available for each.

What is a Pushbutton?

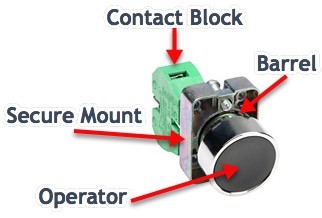

A pushbutton is basically a mechanical device with a mechanism designed to activate an electrical circuit when operated. Pushbuttons are available with various mechanical and electrical configurations.

The following is a list of some common pushbutton features and their purpose:

- Barrel Size: This is the diameter of the pushbutton barrel. This size is important to make sure it fits properly in the opening of the enclosure, panel, or wherever it will be mounted, and to maintain a NEMA rating of an enclosure.

- Action: This determines how the pushbutton will activate the electrical circuit. For example, a pushbutton can provide momentary contact, it may need to stay in pushed position until pushed again, or it may need to be twisted to release the action.

- Contact Type: Pushbutton electrical contact configurations include normally open, normally closed, or a combination of both.

- Operator Color: Pushbutton operators are available in many colors to allow color coding for different

functions. - Operator Size: Pushbutton operator is available in various sizes that include oversized operators that are more visible and provide more surface to push.

- Operator Type: Pushbutton operators are available in types such as double-headed, extended, flush and mushroom.

- Voltage Ratings: Pushbuttons are designed to service common AC or DC voltages to suit specific needs.

- Agency Approval Ratings: Pushbuttons are available in combinations of metal and plastic materials designed to withstand different environments from a basic pushbutton that does not require any special rating to IP69K rated pushbuttons specially designed to be totally sealed and withstand harsh cleaning conditions to serve food, pharmaceutical and medical industries.

- Emergency Stop: These pushbuttons are designed to provide a very simple way to quickly and completely freeze a machine’s operation to prevent injury to workers or costly damage to the machine.

Visit our pushbuttons overview page

What is a Switch?

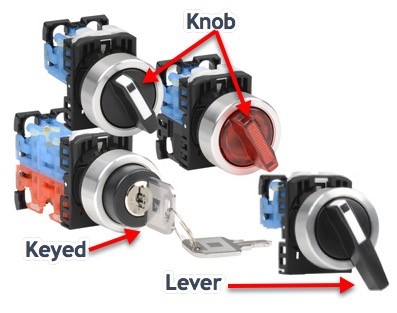

The purpose of a switch is similar to the pushbutton, being a mechanical device with a mechanism designed to activate an electrical circuit when operated. Switches differ from pushbuttons in that they typically use knobs or levers to perform the action.

The following is a list of some common features for switches and their purpose:

- Barrel Size: This is the diameter of the switch barrel. This size is important to make sure it fits properly in the opening of the enclosure, panel, or wherever it is mounted.

- Action: This determines how the switch will activate the electrical circuit. A switch can provide a maintained position, momentary contact switching, or other options.

- Contact Type: Switches’ electrical contact configurations include normally open, normally closed, or a combination of both.

- Operator Color: The switch’s operator knob is available in many colors that allow color coding for different functions.

- Operator Type: A switch’s operator is typically available in types such as keyed, knob and lever.

- Voltage Ratings: Switches are designed to service common AC or DC voltages to suit specific needs.

- Agency Approval Ratings: Switches are available in combinations of metal and plastic materials designed to withstand different environments, from a basic selector switch that does not require any special rating to IP69K rated selector switches specially designed to be totally sealed and withstand harsh cleaning conditions to serve food, pharmaceutical and medical industries.

Visit our pilot devices overview page.

Indicators

Indicators are signaling devices that indicate the current status of a machine, system and/or a process.

There are numerous indicating devices available to fit specific needs/purposes, from a single indicator light to assemblies of multiple lights and audible indication devices.

The following is a list of some common features available for indicators:

- Mount Size: The mount size is important to make sure it fits properly wherever it is mounted.

- Light Function: Indicators are available with various light functions that include permanent light, flashing light, and blinking light.

- Audible Option: Some indicators include an audible alarm option, usually used for warning or emergency indication, by providing a visual and audible notification to ensure it is not missed.

- Light Color: Indicators are available in many colors, allowing different conditions to be identified by the color.

- Voltage Ratings: Indicators are designed to service common AC and DC voltages to suit specific needs.

- Agency Approval Ratings: Indicators are available in combinations of metal and plastic materials designed to withstand different environments, from a basic indicator light that does not require any special rating to IP69K rated stack lights designed to be totally sealed and withstand harsh cleaning conditions to serve food, pharmaceutical and medical industries.

AutomationDirect offers an extensive line of quality and robust pilot devices made by reliable manufacturers such as Fuji, Eaton, IDEM, Schmersal, WERMA, and PATLITE. These devices provide easy and reliable operation and protection for your employees and machinery.

To read more articles about control & signaling devices, click here.