It’s well known that human beings are visual creatures, and we would all choose a pretty picture over boring text any day. Just look at the popularity of image-based apps like Instagram or Snapchat and it’s obvious that images are king. But on the scientific side, it’s believed that our brains can process visual information 60,000 times faster than text, with 90 percent of information transmitted to the brain being visual, and over half of the brain being devoted directly or indirectly to vision. Knowing that, one can conclude that using a visual representation of a machine or automated system would allow for faster recognition and understanding of system variables. And that’s where the HMI comes in to play.

What is a HMI?

The HMI or Human Machine Interface allows operators to “interface” with the system they oversee. It provides a visual overview of the automated system’s status and direct control of its operation. An HMI’s graphical screens can be programmed to display important status and control information to the operator. Pictures, icons, sounds, and colors can all be used by HMIs to visually represent different operating conditions. And many HMIs deploy touch screen technology for user interaction with elements displayed on the screen. Now that ‘What is an HMI?’ has been answered lets talk about what they can do.

What can a HMI do for you?

Let’s say you need to decrease the temperature of a PLC controlled industrial oven in your plant. You could do that by connecting to the PLC with the programming software and making the program changes online. Or you could install a potentiometer to adjust the temperature setpoint blindly without any real-time indication of how the system is reacting. Or you could enter the new value directly by tapping on the HMI screen. By the way, the HMI also displays the current temperature of the oven, a historical plot of temperature fluctuations over time, and will warn you if you set the temperature too low. In this case, the HMI’s convenience and functionality wins hands down. And that’s just one scenario. There are many situations where HMIs reign supreme over pilot devices. Think about modifications. What would it take in terms of wiring and mounting to install three new pushbuttons on a control panel? Not to mention having to buy them in the first place. With an HMI, it’s all in the program. Adding or removing objects, like buttons, on the screen take no time at all and doesn’t cost anything extra. In fact, most HMIs have object libraries that consist of numerous buttons, switches, dials, etc. that can be easily inserted into position on the HMI screen – usually with a simple drag and drop. With the many graphical objects in one small HMI you could replace hundreds of mechanical control devices around your plant.

Here are a few more benefits HMIs provide by interfacing seamlessly with a PLC-based control system:

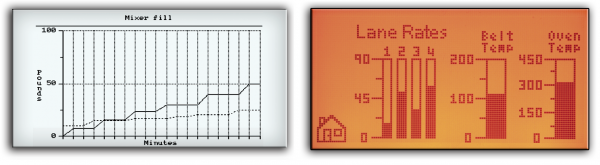

Line/Bar Graphs – Display real-time process values over time with line graphs or in easy-to-read bar graphs.

Data Entry – Easily change process variables with a pop-up numeric keypad on the screen or with increment/ decrement arrows.

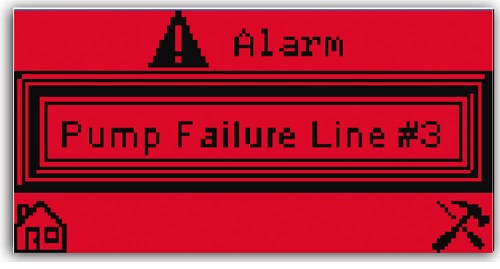

Alarming – See fault indications with detailed descriptions that aid in troubleshooting.

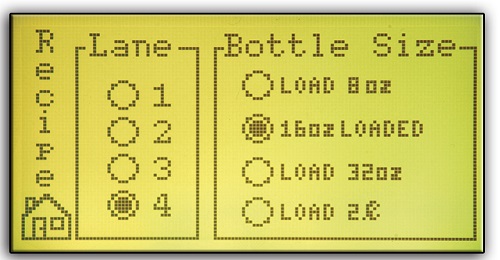

Recipe Functions – Change numerous operating parameters with one click. Recipe buttons transfer multiple values from PLC source registers to PLC destination registers and/or from the recipe table to PLC destination registers.

Communication – HMIs also provide communication channels for easy upload/download of programs, PLC communication and industrial networking.

Advanced features – The more advanced HMIs can also provide email capability so the HMI can email important data to you, web server functionality so you can log on to the HMI from anywhere in the world, data logging so you can record production data for future reference, and mobile apps for your smartphone so you can check on production while on the go.

What does an HMI cost?

HMIs can vary greatly in both performance and price. But for a simple application, one where you are replacing a half dozen indicator lights, micro HMIs can be surprising competitive. Take the C-more Micro HMI for instance. The basic 3-inch model starts at $103 with free software. Now, if you were to purchase 6 panel-mounted signal beacons you might pay as little as $183 (AutomationDirect.com has them starting at $30.50 each). That’s a great price but compared to the C-more, you’re paying a much higher cost for much less functionality. In fact, you could purchase a CLICK PLC to go along with the C-more Micro and still save money over the beacons:

$183 (beacons) vs $103 (HMI) + $69 (CLICK PLC) = $172 (PLC and HMI)

**all prices are as of 5/4/2021**

“But what about wiring and installation?” Just like with the beacons, you would have to mount the HMI to a panel. But instead of wiring numerous signal wires to the indicator lights, wiring an HMI into a control system with a PLC is just a matter of connecting one communications cable (serial, Ethernet, etc.) between the HMI and PLC. The C-more Micro HMI makes installation even easier with applications using AutomationDirect PLCs, like the CLICK, since the HMI can be powered as well through the communications link.

In any project, cost is a primary concern. Micro HMIs offer many benefits over mechanical pilot devices including more functionality, time-saving modifications and overall cost. So if you’re thinking the budget, or the system itself, is just too small for an HMI, take a look at the micro HMI market. You might be surprised at what you find.

For more articles related to HMIs click here.