The AutomationDirect WinPLC was an advanced controller for its time, and users who need to modernize existing installations have options for rapid upgrades.

In the late 1990s, Windows CE was a popular lightweight operating system because it was a good fit to reliably operate various consumer electronics and industrial components, including the AutomationDirect WinPLC controller. However, updates from Microsoft ended about a decade ago and support is sunsetting soon. This article by Scott Martin, founder of KCC software, published on PanelBuilderUS in August 2023 and titled Migration Strategies for Supporting Legacy Automation, describes how KCC is supporting clients who need to update their WinPLC systems.

Transitioning from Windows CE to the Modern Era

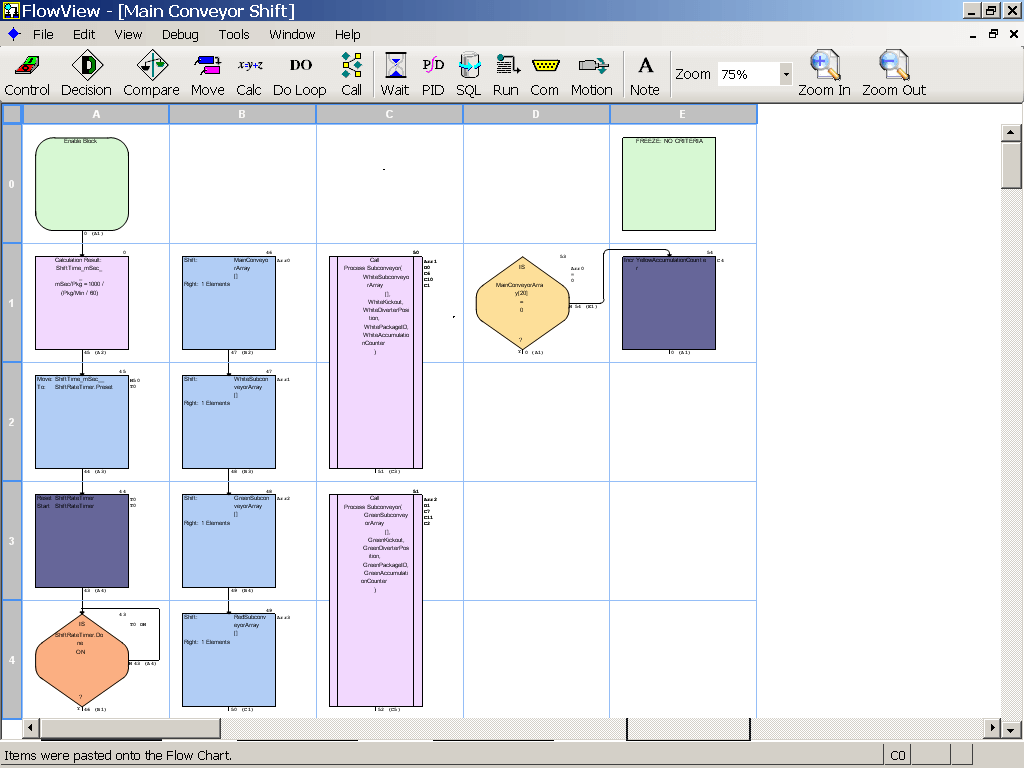

Windows CE featured a user-friendly graphical user interface, making it possible for industrial devices like the WinPLC—a hybrid programmable logic controller (PLC)—to include more advanced PC-like functionality, such as additional computing power, flowchart programming instead of ladder logic, and visualization. Many users and OEMs took advantage of these capabilities, producing forward-thinking systems that remain in operation today.

However, considering the lack of Windows CE support—along with new requirements for users to incorporate updated logic, remote cloud access, and improved secure data connectivity—many users need options to upgrade these systems. Industrial controls devices typically have long lifecycles, and there is always the thought that “if it ain’t broke don’t fix it,” but it is always better to plan an upgrade instead of being forced into it.

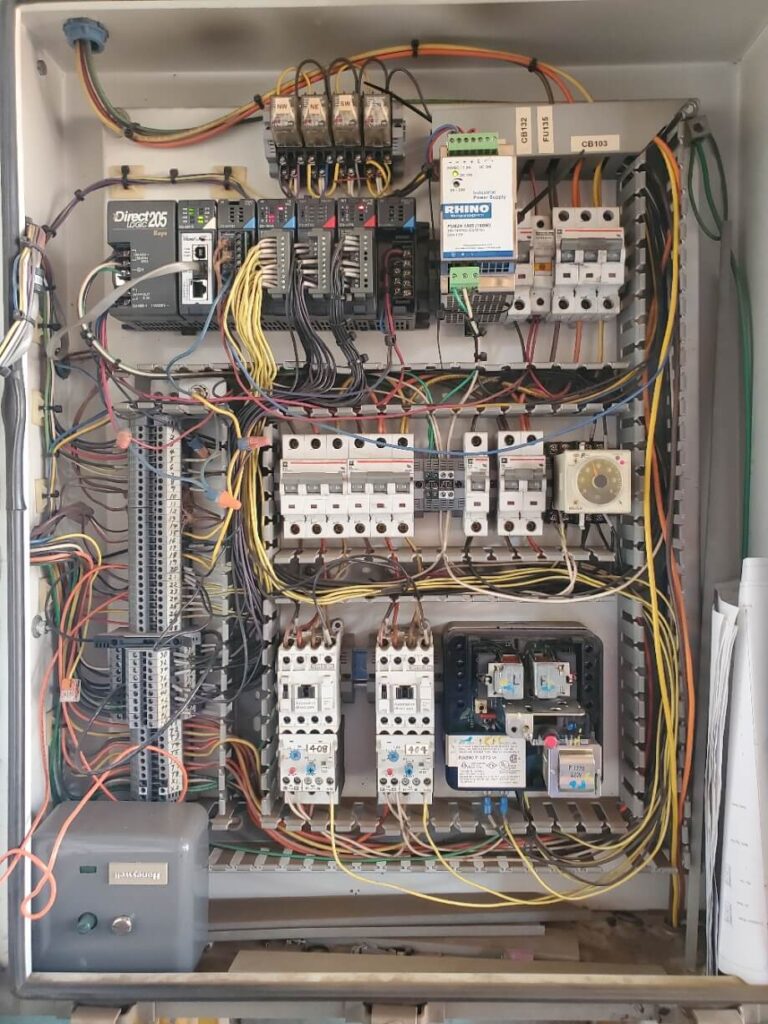

Because the WinPLC—which was retired in 2018—shares the same AutomationDirect DirectLOGIC DL205 form factor and I/O connectivity, the latest and more traditional AutomationDirect D2-262 CPU provides a convenient path forward. From a hardware standpoint, the WinPLC can simply be removed and replaced with the latest processor.

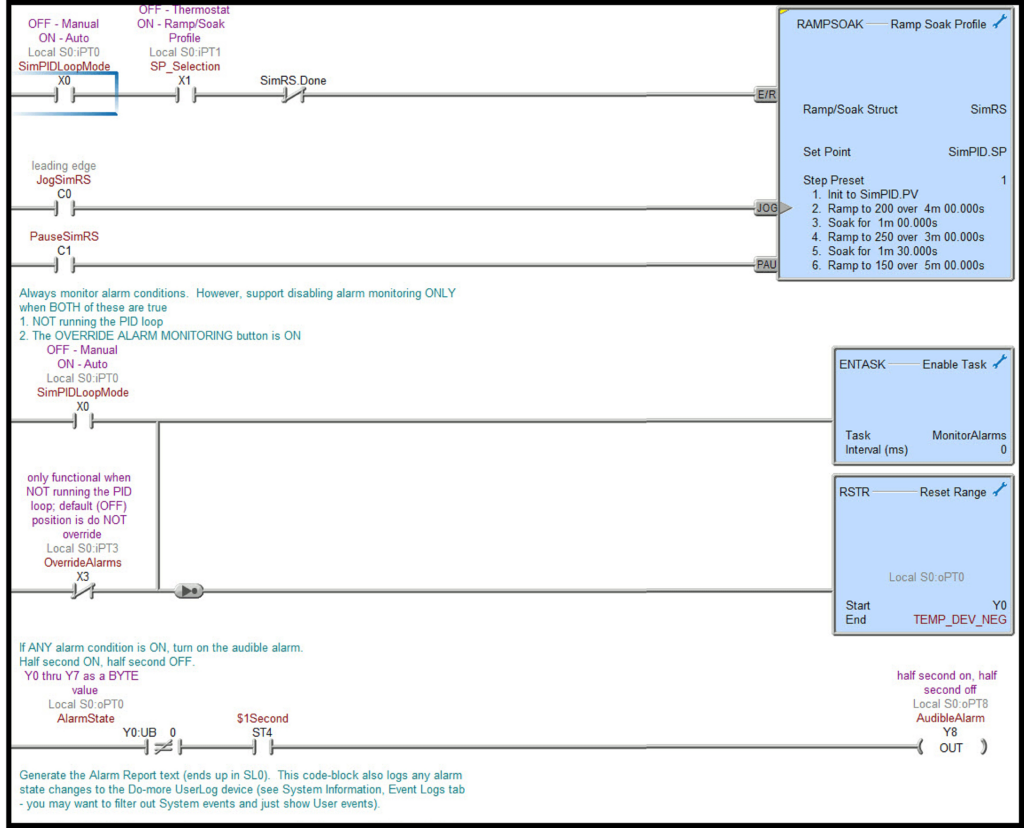

The more modern CPU is faster and incorporates many other features, but it is programmed in ladder logic instead of flow chart logic. While this looks quite a bit different, flow charts are usually heavily documented, which makes them more readable than ladder logic.

With their expertise in software systems and upgrades, KCC has had great success developing a methodology for converting these programs offline, which leads to fast on-site commissioning, resulting in significant time and labor savings as compared to a complete rip-and-replace.

KCC has supported many clients, including those in the semiconductor industry, by performing these upgrades as a low-risk path to keeping existing assets in operations, while avoiding extensive downtime or large capital investments. These projects are also a chance to add valuable functional upgrades and operator interface enhancements.

Even though support for Windows CE is lapsing, migration doesn’t have to be painful. When it’s time for an upgrade, don’t “win-ce”. Rather, look to proven and trusted suppliers and SIs with a reputation for long-term support of their customers.

Visit the AutomationDirect.com website today to explore products that can help your company keep productive equipment running for years to come, while adding new capabilities.

All figures courtesy of KCC Software