When a “do-it-yourself user” makes the decision to automate, integrate or just simplify applications and machinery, the world is his/her oyster. In today’s world of industrial automation controllers there are many options. Depending on your specific needs, you could select a very extravagant or very basic automated system. The automation application could range from simple relays and timers to coordinate a sequence, to larger distributed controls and SCADA (Supervisory Control and Data Acquisition) systems for your complex control, calculation and reporting applications.

Regardless of design complexity, you must determine how to program your control system. Depending on your background and areas of expertise, this can vary greatly. The majority of controllers today offer a variation of ladder logic control at a minimum. Ladder Logic is a programming language born with the origination of the PLC (Programmable Logic Controller). The first PLCs were basic “relay replacers” in industrial controls, so Ladder Logic emulated an electrical schematic with power rails and rungs. Instructions consist of conditional contacts that, when enabled in a specific sequence, will energize an output coil or trigger an event.

Based on data from the Programmable Logic Controllers and Programmable Automation Controllers (PLC, PAC) Product Research study conducted by Control Engineering (September 2008), virtually all respondents used ladder diagrams to program PLCs / PACs, which is almost double the usage of any other programming language. However, if your background expertise is not electronics, and is more focused on other programming languages, ladder logic can be foreign and confusing. This is where a hybrid PC-PLC solution, such as WinPLC, can benefit you.

The WinPLC

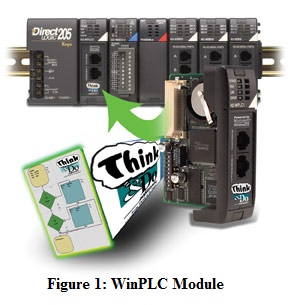

The WinPLC is a Windows CE based CPU (Central Processing Unit) for the DirectLOGIC 205 series PLC (DL205) from AutomationDirect. A key feature of the DL205 series is that it allows you to manipulate your application’s I/O (inputs and outputs) in a compact form factor; it offers multiple options for system control, such as deterministic control and connectivity to other control devices and business systems. The WinPLC (H2-WPLC3-EN) is one CPU option for this series; it comes pre-loaded with Think & Do PC-based control runtime software, and uses its flowchart programming environment. (Fig. 1)

The WinPLC is a Windows CE based CPU (Central Processing Unit) for the DirectLOGIC 205 series PLC (DL205) from AutomationDirect. A key feature of the DL205 series is that it allows you to manipulate your application’s I/O (inputs and outputs) in a compact form factor; it offers multiple options for system control, such as deterministic control and connectivity to other control devices and business systems. The WinPLC (H2-WPLC3-EN) is one CPU option for this series; it comes pre-loaded with Think & Do PC-based control runtime software, and uses its flowchart programming environment. (Fig. 1)

In keeping with its philosophy of offering the best value in the automaton industry, AutomationDirect has recently cut the price of its Think & Do programming software for the WinPLC processor from $695 to FREE. Prior to this change, the lowest cost option for programming the WinPLC processor with Think & Do was to purchase the programming package for $695. Now, customers can download the Think & Do v8.04 keyless development demo package for free, which includes the same development software that customers receive when purchasing the full Think & Do development package for $1,895.

Like most PC-based control programming software packages, Think & Do consists of a development package that runs on a PC, and one or more runtime keys that reside on real-time industrial controller application targets. The free Think & Do demo package has no limits when it comes to development – only for runtime targets, and these limits don’t affect the WinPLC since it comes pre-loaded with Windows CE and Think & Do runtime software.

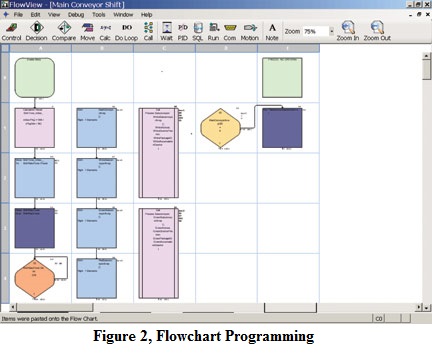

Customers can download the Think & Do v8.04 Keyless Development Demo package for free, create software applications with Think & Do, and download these applications to an unlimited number of WinPLC targets. (Fig. 2)

This begs the question, “Why should I choose the WinPLC?” The answer is very simple, but depends upon personal preference. Do you prefer a more traditional style controller with a ladder logic programming method? If so, the WinPLC is probably not for you. However, if you are looking for a processor with built-in Ethernet and serial ports that handles advanced data manipulation, string arrays and complex math functions in an easy-to-follow Flowchart programming environment, then the WinPLC may be what you need to simplify your application needs.

With Flowchart programming, if you can visualize your process and write a simple process flowchart, your programming is complete. When you are looking for PC-based control characteristics, but prefer the rugged form factor of a PLC, the WinPLC is the control solution for you.

By Jeff Payne,

Product Manager, PLC/IO and PC Control

Originally Published: June 1, 2010