The safe torque off function built-in to modern VFDs significantly improves the integration of emergency stops.

Kevin Kakascik, Technical Marketing Engineer with AutomationDirect, wrote an article for the May-June 2021 issue of Industrial Equipment News. The article, titled Motor Drive Safe Torque Off Improves Equipment Safety, explains the capability and how to use it. Here’s a summary, click on the link above for the full text.

Machinery and equipment motors are commonly operated by variable frequency drives (VFDs) to provide motor speed control and energy savings. However, designers must incorporate emergency stop (e-stop) electrical interlocks to stop the motor if any unsafe condition is sensed or an operator triggers an e-stop device.

Traditional VFD E-Stop Methods

For older VFDs, designers usually installed a power contactor upstream and/or downstream of the VFD. An upstream contactor would de-energize power into the VFD, but the output could have some residual power. A downstream contactor disconnected the motor but could damage some VFDs. The control circuit could be interrupted to stop the motor, but this was not a fail-safe method. None of these solutions were ideal.

E-Stop Modern VFDs with STO

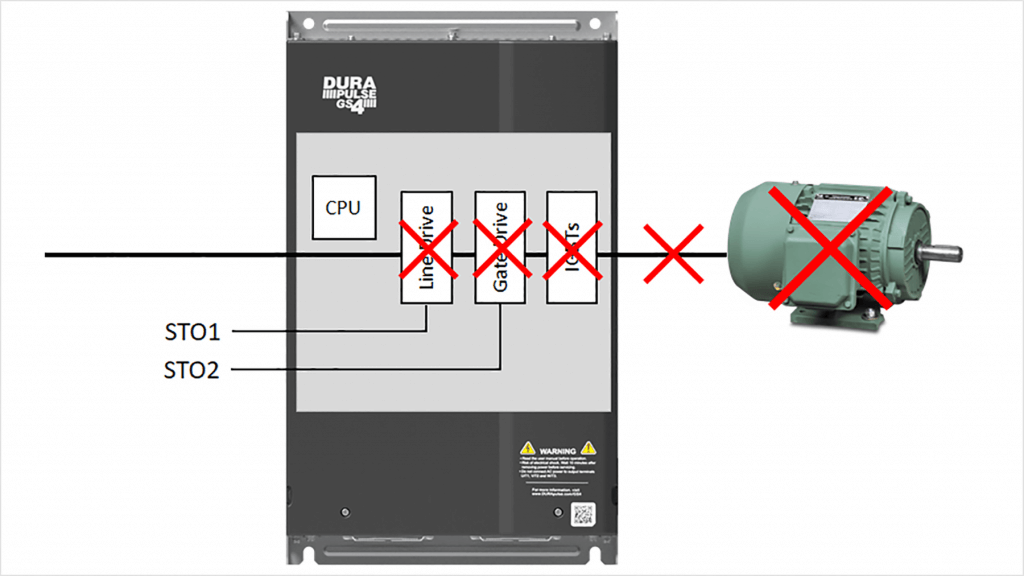

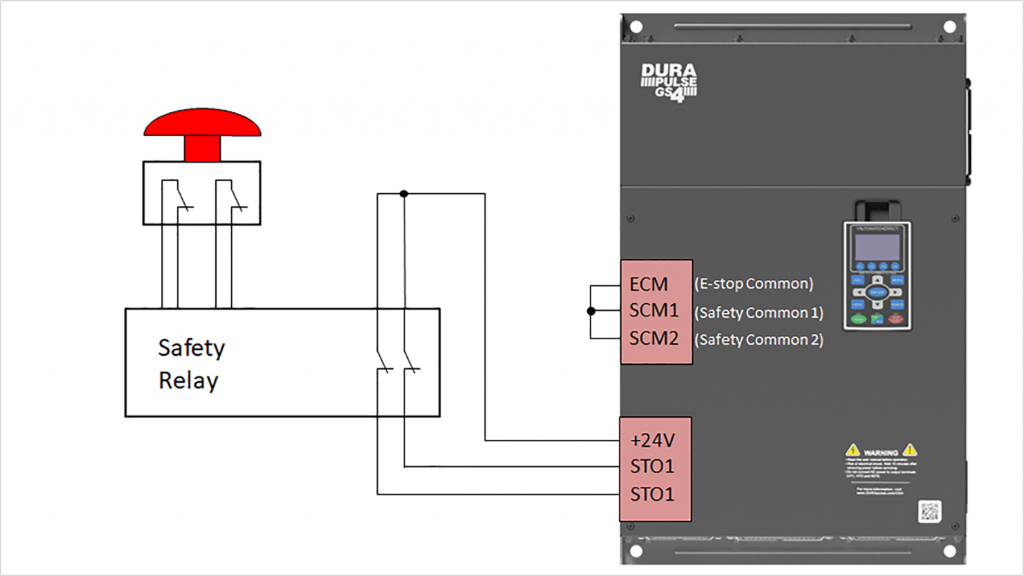

Newer—and higher quality—VFDs like the AutomationDirect DURApulse GS4 series [PD1] offer an integrated safety feature known as safe torque off (STO), a function tested and certified by a nationally recognized test lab. STO implementations are designed to be fail-safe by completely removing output torque and allowing the motor to coast to a stop.

This is possible because redundant STO circuits are connected right to the driver circuits of insulated-gate bipolar transistors (IGBTs) and can positively prohibit the IGBT from sending current to the motor. It is recommended to use dual-channel safety relays for these circuits instead of general-purpose relays. Once an STO has been activated to stop a VFD, the VFD will be inhibited from restarting until the condition is cleared and a reset is triggered.

Note that even with an STO active, there is still the risk of being shocked from the motor leads, so workers should always follow a proper lock-out-tag-out procedure.

STO is a significant safety feature found on new variable frequency drives. It helps designers, OEMs, and end users achieve better equipment safety performance while requiring less hardware and lower overall complexity than traditional methods.

Designers must still understand and follow all applicable codes and standards, and perform a risk assessment, when designing STO circuits. However, STO is often the best way to deliver improved VFD motor safety.

Read more articles about motors here!