When the mechatronics students at Catawba Valley Community College (CVCC) in Hickory, North Carolina, went looking for a suitable project to challenge their recently acquired PLC and HMI skills, they didn’t have to go far.

The Problem

The college’s Manufacturing Solutions Center (MSC) in nearby Conover needed a way to monitor the status of a large group of washing machines and dryers and display that information for the technicians who use them.

The Manufacturing Solutions Center performs a wide variety of product development, prototyping, engineering, marketing and contract testing procedures for companies across the country. They have considerable expertise with product development and rapid prototyping, including reverse engineering services, 3D modeling and printing, Laser scanning and cutting, CNC milling, and various forms of plastic molding. They offer training in LEAN manufacturing, supply chain management, and many other industrial related topics.

The Manufacturing Solutions Center performs a wide variety of product development, prototyping, engineering, marketing and contract testing procedures for companies across the country. They have considerable expertise with product development and rapid prototyping, including reverse engineering services, 3D modeling and printing, Laser scanning and cutting, CNC milling, and various forms of plastic molding. They offer training in LEAN manufacturing, supply chain management, and many other industrial related topics.

As an accredited ISO/IEC testing facility, they perform a wide variety of tests for the textile and garment industry. These tests include: antimicrobial testing, compression testing for textiles, defect analysis, fiber analysis, flammability testing, Formaldehyde/Phenol/pH testing, hosiery testing, lead testing, microscopy testing, physical testing, furniture testing, weathering/lightfastness testing, and Yarn/Fabric/Garment Analysis. For some of these tests, technicians often have to wash and dry various materials – sometimes repeatedly – in a lab filled with washers and dryers. These washing machines and dryers are in very high demand, and the technicians were having a difficult time keeping track of which machines were in use, and which were idle.

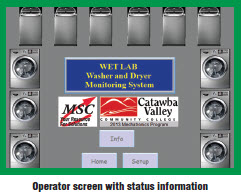

Jim Thomas, Mechatronics professor at CVCC, explains, “The challenge presented to the mechatronics students was to use off-the-shelf industrial automation components to determine the state of each of the machines in the ‘wet lab’ and to display that information clearly and concisely for the technicians, some of whom might be working in distant areas of the testing facility.”

The students decided to limit themselves to “non-invasive” forms of monitoring as opposed to tapping into or altering the electronic control circuits built into the machines, such as the “cycle complete” lights or audible alarms built in to the washers or dryers. They were concerned that this would require long term support and maintenance whenever the washers and dryers needed to be replaced and/or upgraded.

The students experimented with both ProSense™ liquid flow switches and AcuAMP™ single phase AC current transducers from AutomationDirect. While the current transducers were the obvious choice for detecting the operating status of the dryers, the students had some concern that the washing machines would not draw enough current during certain cycles (such as filling and soaking) to activate the transducers. It was thought that monitoring the water flow might also be required. But after thorough testing, the students were able to standardize on the analog current transducers for all the washers and dryers. The students were very grateful to the CVCC maintenance staff, who helped with the hardware installation.

One unexpected troubleshooting opportunity arose when a few of the dryers seemed to periodically stop drawing any current, while they were obviously still running. It was quickly deduced that once the dryers reached their temperature setpoints, the heating elements were cycling on and off to maintain the desired temperature.

As luck would have it with the two-phase input power, the current sensors on some of the dryers were monitoring the phase that also powered the motor (thus showing current draw throughout the entire cycle), while others were on the “heater only” phase, and would report the periodic on/off current flow. Simply moving the transducers over to monitor the other phase corrected the issue.

The signals from the current transducers are wired into analog input modules on an AutomationDirect Do-more PLC. The students were familiar with both the CLICK™ PLC and the Do-more™ PLC from previous PLC coursework. They chose Do-more primarily based on its Ethernet communications capability as well as its greater expandability for possible future enhancements. “The Do-more PLC was the obvious choice,” reports design team member Cris Mura. “It’s easy to program, has a handy, built-in simulator, and its Ethernet connectivity interfaces perfectly with the C-more HMI.”

During the design phase of the project, the mechatronics team created a mock-up of a few HMI screens and presented them alongside some discrete multicolor indicator lights as possible notification options.

The MSC technicians had a clear preference for the C-more panel. The 12” C-more operator interface is mounted inside the wet lab for local use by the technicians, but the standout feature of the C-more HMI for this application is its “remote access” capability, because the technicians don’t actually spend very much time in the wet lab. They only visit the lab in order to move the textile products in and out of the washers and dryers; many of them had resorted to wearing stopwatches around their necks as reminders to check on materials in the washers and dryers.

The MSC technicians had a clear preference for the C-more panel. The 12” C-more operator interface is mounted inside the wet lab for local use by the technicians, but the standout feature of the C-more HMI for this application is its “remote access” capability, because the technicians don’t actually spend very much time in the wet lab. They only visit the lab in order to move the textile products in and out of the washers and dryers; many of them had resorted to wearing stopwatches around their necks as reminders to check on materials in the washers and dryers.

To take advantage of the C-more Remote Access capability, the students acquired two separate, low cost PCs, each with a 32” flat screen LCD monitor, which they mounted in two of the areas where technicians spend their time performing hands-on testing and other tasks. Now the technicians simply glance up at the screens to see the status of any washer and dryer being used for their tests.

These two PCs are equipped with large, easy-to-see screens networked to the C-more panel over Ethernet; both screens provide an exact copy of the information which is visible on the actual C-more device itself.

Tony Whitener, the Special Projects Director at MSC, is delighted with the solution, “We were so pleased with the collaboration between the continuing education students in the Mechatronics program, the educational outreach and technical support from Automation Direct, and our own in-house technicians and maintenance staff. All parties worked together seamlessly to produce a well thought-out monitoring system. It’s a definite productivity enhancement for the Manufacturing Solution Center.”

Tony Whitener, the Special Projects Director at MSC, is delighted with the solution, “We were so pleased with the collaboration between the continuing education students in the Mechatronics program, the educational outreach and technical support from Automation Direct, and our own in-house technicians and maintenance staff. All parties worked together seamlessly to produce a well thought-out monitoring system. It’s a definite productivity enhancement for the Manufacturing Solution Center.”

Now that the monitoring system is installed and operating, students are already thinking of enhancements. Cris Mura explains, “The C-more Remote App for iOS is one upgrade we are considering. Once the C-more is accessible from the MSC’s wireless network, then anyone with an iPhone or iPad will be able to monitor the ‘wet lab’ status on their mobile device.” The e-mail and text message features of C-more might even allow technicians to set-up custom text message alerts in the near future.

The student team is comprised of Derrick Artis, Brian Bowersox, Ben Burleson, Robert Fonnesu, Rusty Gabriel, Greg Harris, Stephen Lathrop, Cris Mura, and Josh Rudisill.

Jim Thomas, their instructor and the continuing education mechatronics program coordinator at Catawba Valley, was very complimentary about the students’ efforts. “Tony and I discussed the project, presented it to the students, and after that I stepped back and let the students run the project. My involvement was purely an advisory role. They worked with the MSC technicians to define the requirements, debated several possible solutions, and presented their best ideas to the MSC staff to allow them to arrive at a final solution that would accommodate their preferences for the system operation. Then they designed and built the system and coordinated the installation with the CVCC maintenance staff. I’m proud of them not only for the great system they implemented, but also for the professional manner in which they achieved the project.”

Visit http://youtu.be/LiCGII-v0-g to view a video of this automation system in action.

Learn more about CVCC here: http://www.cvcc.edu and the MSC here: http://www.manufacturingsolutionscenter.org/

By Chip McDaniel,

AutomationDirect

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Posted: Sept. 24, 2013