The early 20th Century was full of technological advances and great historical moments. In 1928, Charles Lindbergh and Amelia Earhart were in the news for their famous feats of flying. The first television broadcasts began to appear on tiny black and white screens. Mickey Mouse was making movies – with sound. And, sliced bread made its debut. Among the less publicized events of 1928 was the founding of the E.M. Wiegmann & Co. in Freeburg, IL by Edgar Maurice Wiegmann who had an incredible desire to work with metals.

Since then, the Wiegmann Company’s history itself reads like a page from a U.S. history book. From surviving the Great Depression to utilizing today’s technological advances, Wiegmann has provided history with a chapter on successfully developing, evolving, and sustaining a business for more than 80 years.

Back in 1928, Wiegmann started the business making metal outlet boxes both in two-gang and four-gang configurations. The need for such products grew as the use of electricity expanded throughout the country in both homes and businesses. As electricity became essential, so did the outlet boxes which helped the company to establish itself even in tough economic times. When World War II began, Wiegmann expanded its operations to assist with the war effort. The company manufactured ammo boxes for the military as well as Post Office mail boxes for the United States Postal Service.

From Outlet Boxes to Ammo Boxes

During WWII, there was a great demand for the ammo boxes provided by Wiegmann. In fact, there was such high use of this product that it put additional pressure on the company to further expand its operations. The rapid expansion need was solved by adding another  fabrication facility through the acquisition of a company called KEMCO. As the war effort winded down, Edgar Wiegmann’s purchase of KEMCO allowed the company to easily transition from the war-driven ammo boxes into a different product more suited to peacetime — the switch box.

fabrication facility through the acquisition of a company called KEMCO. As the war effort winded down, Edgar Wiegmann’s purchase of KEMCO allowed the company to easily transition from the war-driven ammo boxes into a different product more suited to peacetime — the switch box.

During the post-World War II economic boom, Wiegmann too ushered in its own strong growth with another expansion in 1957 by acquiring ACE Metals. Both companies merged and the ACE Metals products were brought into the Wiegmann line. This line then expanded to include wireway, raceway, and gutter products. Such products were in high demand as they are used to transfer long runs of electrical wire often found near the ceilings of buildings. All building codes require the run of wires be enclosed in some type of wireway, raceway or gutter system.

In late 1958, the founder, Edgar Maurice Wiegmann, passed away and his son Harold Edwin Wiegmann took over the company and added yet additional capacity by purchasing another facility — this time back where the company began in Freeburg, IL. As his father did before him, Harold looked for opportunities to expand the company but never straying far from the essential “metal box” business that had sustained them for 30 years.

NEMA and Wiegmann

With switch boxes and metal stamping keeping the Wiegmann manufacturing line at full capacity, Harold was interested in pursuing other opportunities. Fortunately, another organization was also looking to build new relationships. The National Electrical Manufacturers Association (NEMA) and Wiegmann found that their mutual desire to advance the availability of electricity could benefit both organizations. NEMA was a natural fit for Wiegmann because of the wireway product line. Wiegmann supported NEMA in its mission to help “build a new electrical society.” By opening its doors to working with Wiegmann and other companies in the late 1950s, NEMA offered help with “joint promotional and technical development projects” which allowed Wiegmann to quickly move into a new line of indoor and outdoor electrical enclosure products.

Triumph Over Tragedy

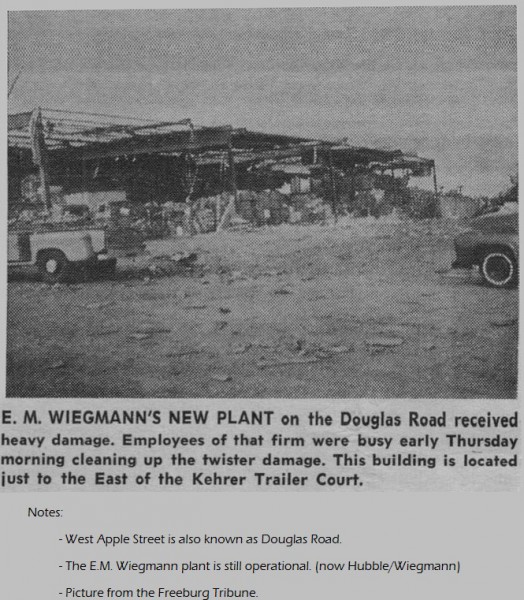

T his new line of enclosure products was so successful, Wiegmann expanded its facilities again in 1964 when the company replaced all of it fabrication sites with a newly built building located not far from its founding site in Freeburg, IL. This 42,500 square foot facility was the company’s show piece but, in May of 1968, was devastated when a huge tornado ripped through the area nearly demolishing the Wiegmann building.

his new line of enclosure products was so successful, Wiegmann expanded its facilities again in 1964 when the company replaced all of it fabrication sites with a newly built building located not far from its founding site in Freeburg, IL. This 42,500 square foot facility was the company’s show piece but, in May of 1968, was devastated when a huge tornado ripped through the area nearly demolishing the Wiegmann building.

The tornado that destroyed many areas of Freeburg was part of a severe weather outbreak that hit 10 states in the Midwest on May 15 and 16 in 1968. It’s estimated that the F-3 tornado hit the small town just before 10p.m. and severely damaged neighborhoods, a soda storage building, the Wiegmann plant, the town’s funeral home, and the Freeburg Milling Company. The tornado also destroyed a church, the American Legion building, part of the high school, and many homes in a trailer park. The storm was so severe that, by one account, girders from the Wiegmann plant were found four blocks away. (Sources: Ford-Mobley.com, the Freeburg Tribune and Belleview News Democrat.)

Wiegmann Joins Hubbell

After rebuilding from the storm, Wiegmann continued on its pattern of growth for the next two decades and expanded its facilities six times between 1970 through 1989. With so much success, Wiegmann caught the attention of Hubbell Inc. based in Connecticut. In 1994, Hubbell acquired the E.M. Wiegmann Company and helped turn it into a nationally recognized enclosure contender. The current Hubbell-Wiegmann facility is an automated plant designed to handle more than 7,000 stocked electrical enclosure products.

Today’s electrical enclosure industry covers an array of markets, including:

- Commercial – products are designed as simple termination, power management, up to wire management.

- Industrial – products are manufactured for controlling power supply and wire management for tooling/equipment, robotics, oil/gas/mining, petrochemical, pharmaceutical, food/beverage, and more.

- Environmental Control – products are built to protect drives, wiring, and components from extreme conditions.

The materials used in manufacturing these products range from carbon steel, galvanized steel, stainless steel, and non-metallic resources.

All Hubbell-Wiegmann products are “true tested to meet the customers’ needs,” explained a member of the Wiegmann management team. “We have a long-standing history in the enclosure market and the products we design are driven with the voice of the customer in mind. Many of our products stem from the construction of a special product that was requested to meet a specific market demand. After it was built to a customer request or spec, that product is often modified and then becomes a stock item in the electrical market. That’s how we listen and learn from our customers.”

I t’s that type of listening to customers’ needs that has helped Hubbell-Wiegmann stay at the forefront of the enclosure industry. The company also incorporates new technology such as highly sophisticated laser cutting machines, metal bending methods, and welding methods into its design program combined with good old-fashioned ingenuity. As a result, Hubbell-Wiegmann is able to produce products in a manner that was not long ago even available. Today, a typical enclosure manufacturing facility looks much different than it did just 10 to 15 years ago mainly due to computer-aided technologies that are commonplace today.

t’s that type of listening to customers’ needs that has helped Hubbell-Wiegmann stay at the forefront of the enclosure industry. The company also incorporates new technology such as highly sophisticated laser cutting machines, metal bending methods, and welding methods into its design program combined with good old-fashioned ingenuity. As a result, Hubbell-Wiegmann is able to produce products in a manner that was not long ago even available. Today, a typical enclosure manufacturing facility looks much different than it did just 10 to 15 years ago mainly due to computer-aided technologies that are commonplace today.

Where is Hubbell-Wiegmann headed in the future? A look at its history of exploring new opportunities provides the answer: “The entire enclosure industry is in a fast pace race to provide more product with less resource and labor and yet at the same time introduce new designs capable of being much more flexible when used in the market. The market is focused on product families rather than on specific products with one use – a very different view than in the past,” explains Wiegmann management.

For the almost 90-year-old company that goal of blending future technology with its tradition of perseverance doesn’t seem out of reach. After all the company has experienced and accomplished it still has many more future chapters to contribute to the history books.