Photoelectric, proximity and capacitive sensors are used in a wide variety of machines and industrial equipment, but selecting the best sensor for the job can be confusing. This blog post and the accompanying articles will help you sort out the best sensor for your application. During sensor selection, it’s important to understand sensor requirements and specifications along with the demands of the installation environment. Important selection factors include sensing distance, target type and background.

Important selection factors include sensing distance, target type and background.

Consider these key aspects when selecting a sensor:

Consider these key aspects when selecting a sensor:

- Type of target to be sensed

- Background and objects to ignore

- Mounting space constraints

- Sensor housing and form factor

- Mounting method

- Electrical connections and cabling

Knowing the type of target helps identify the specific sensor technology—either photoelectric, proximity or capacitive. However, it’s also very important to not lose track of the fact that the sensor may also detect the background behind the target or a person walking past the sensor.

Photoelectric Lights up the Target

Photoelectric sensors use infrared, red LED or laser light to detect the object via a variety of different technologies. Retroreflective (reflector needed) and diffuse designs have the emitter and receiver in the same housing, while through-beam sensors have a separate emitter and receiver.

As compared to prox and capacitive sensors, photoelectric sensors are capable of sensing the widest range of objects at the longest distance. But, they are the sensor type most affected by ambient conditions such as dirt and debris, so carefully review the application to identify potential causes of false triggers.

It’s in Proximity

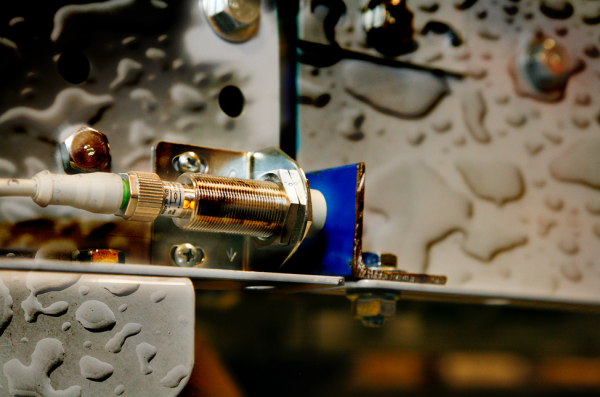

If you are sensing metal, especially ferrous targets, a prox sensor is generally the first choice. These sensors work well in most metal detection applications, but don’t forget to reduce the sensing distance when trying to detect non-ferrous metals like aluminum or stainless steel, as the sensing range may be reduced by 30% to 50%.

Capacitive Considerations

Capacitive sensors detect the density of the sensed target or area, and therefore work best with high-density targets. Because of this, they are commonly used to sense liquid and bulk dry material levels in tanks. Adjusting the gain is key to sensing the material and not the cardboard box or plastic tank wall containing it. Because these sensors can detect a wide variety of objects, ambient conditions may cause false triggers.

Get it Mounted and Connected

Be sure to consider the physical size of the sensor and its electrical connections. While the sensing application may drive the housing style used, physical constraints in the equipment may keep the sensor from fitting into the machine.

Another common specification overlooked is the electrical connection. Incorrectly specifying PNP, used in the US, and NPN, common in equipment delivered from Asia, is a typical error. It’s also important to carefully specify the voltage and signal level.

Specifying the correct cable length isn’t the only concern with the cable as the connector type must also be carefully considered. There are many types of connections, M8 and M12 being the most popular with 3- and 4-pole configurations. Take a little extra time and double check the connection specification to make sure you get it right.

Applications

With careful review of the specifications for the different sensor technologies, it will be clear that there is much overlap in sensor applications. However, with a closer look you will find that some technologies work better for particular applications.

If your target is metal, on a pneumatic or motor driven actuator for example, start with a proximity sensor. Photoelectric sensors are a good starting place when detecting pallets and boxes on a conveyor and other part sensing applications. If you need to monitor tank levels, capacitive sensors are usually your best bet.

Take the time to analyze the application and check that you are meeting the requirements. It’s not just about specifying sensing distance as there are many other options to consider, all of which can affect performance and reliability.

For more information, please see the Sorting out Sensors and the Sensor Mounting Considerations articles in the July 2015 issue of Machine Design magazine. Both articles are authored by Andrew Waugh, Safety and Sensor Product Manager at AutomationDirect.