Although we generally think of industrial enclosures as protecting components inside the box, it is also important to understand how they work with the environment outside the box.

Jody Kinney, product manager at AutomationDirect, wrote an article for the July 2021 issue of Processing titled Thinking Inside and Outside the Box. Here’s a summary, click on the link above for the full text.

Industrial enclosures are necessary to protect internal devices and electronic components from water, dirt, and contaminants. However—for pharmaceutical, clean room, and food/beverage applications—it is equally important to understand how the enclosure interacts with the surrounding environment so the right options can be selected.

More Protection Needed

Hygienic industries commonly use high-pressure/temperature washdowns and chemicals for cleaning. As instruments, PLCs, HMIs, and other automation elements are increasingly used at these facilities, there is a greater need for control panels to protect these devices, while maintaining facility cleanliness.

Enclosure Details

Designers must investigate and specify how enclosures will meet needs with regards to:

- Ratings and standards

- Enclosure materials and finish

- External physical configuration

- Hardware and accessory options

- Gasketing

- Mounting provisions

NEMA, IP, NSF, and ANSI are common rating systems and standards for enclosures and their areas of application, and enclosures are available with a wide variety of features and options to meet most any condition.

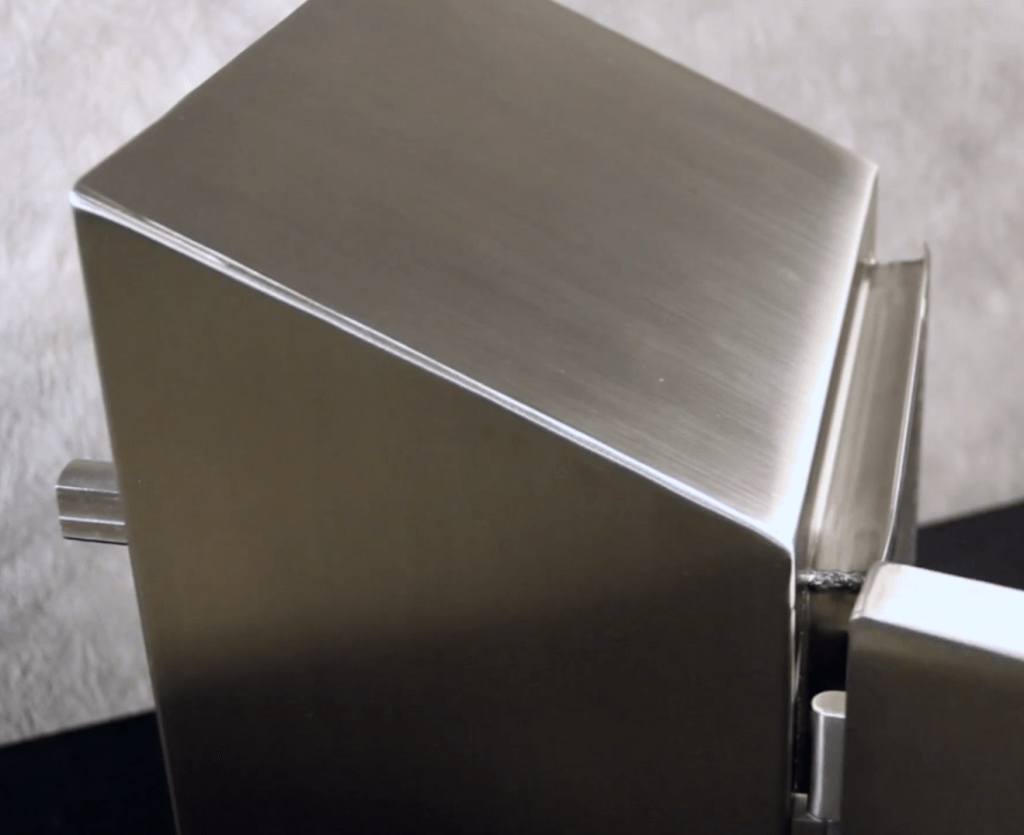

For the most hygienic applications, enclosures are typically fabricated using 300-series stainless steel with a #4 brushed finish, welded and smooth-finished seams, rounded edges, sloped tops and gutters to shed water, and no exposed convoluted surfaces.

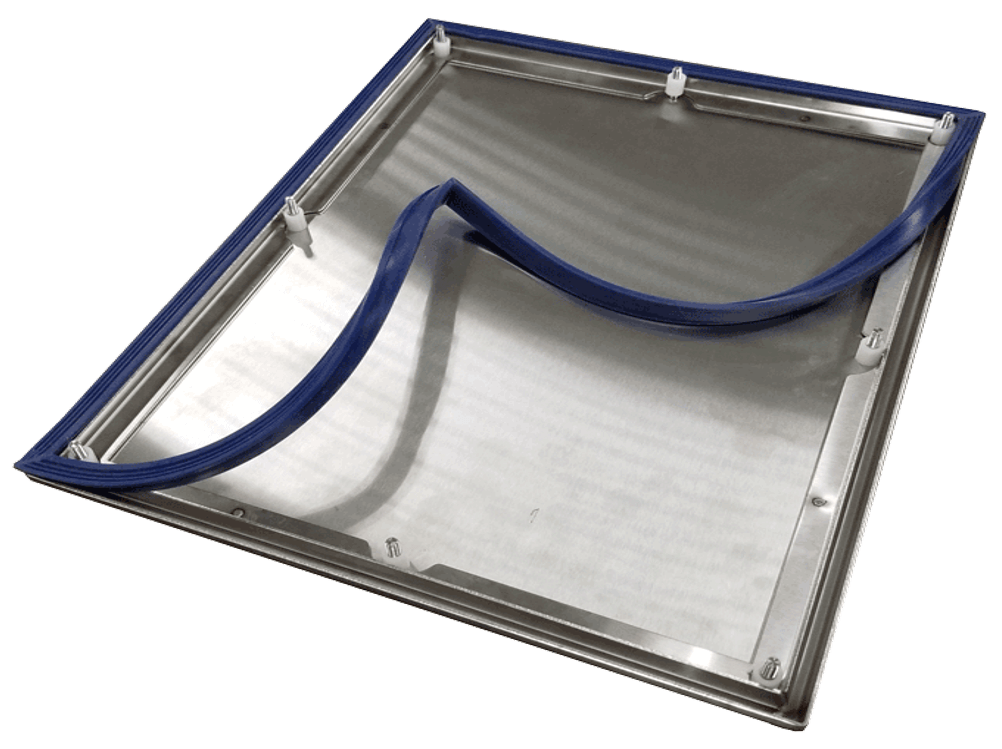

Gaskets are necessary to keep water out but can cause contamination issues if not properly implemented. The most rigorous designs may use both a permanent inboard gasket and a serviceable outboard gasket. Gaskets must remain flexible and never off-gas, and blue silicone material may be used so contamination is more easily spotted during cleaning. Doors may be removeable for deep cleaning.

Enclosure mounting provisions must adhere to similar environmental considerations. Hygienic enclosures are often mounted on wall standoffs or floor-mount legs, making it is easy to clean behind and underneath them.

Protection Inside and Out

The increasing amount of industrial automation is calling for more field devices than ever before to be installed on the plant floor and in facilities, and most need some form of protection.

An industrial enclosure can be just a simple box to protect relatively delicate contents. However, for hygienic and sanitary applications in many industries, enclosure selection takes on much more importance to keep liquids and chemicals out and to keep the surrounding environment impeccably clean.

To get the right enclosure for the job, designers need to understand industry requirements and the available options. AutomationDirect offers a comprehensive line of enclosures and accessories to help users get just what they need.