Most control systems have to make things move, and that usually involves motors. Lifting, pumping, robotics, conveyors, fans – pretty much everything uses a motor of some kind. General purpose one- or three-phase AC motors are great for simple on/off systems; Inverter-duty motors are specifically designed for operation with variable frequency drives or VFDs.

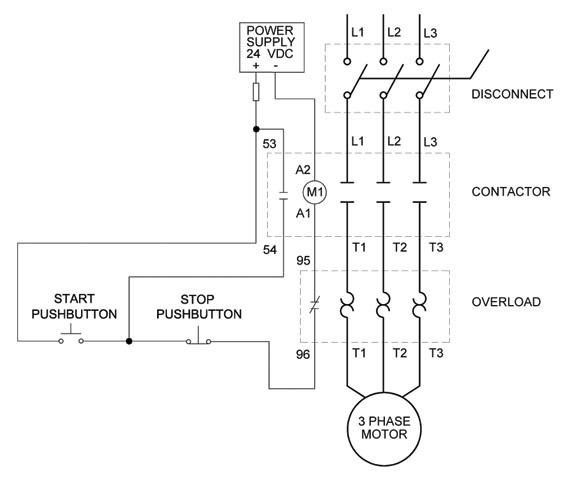

General purpose motors are typically connected to the main power circuit with a master circuit breaker or fuses, and use contactors to enable and disable the power to the motor; overloads protect your equipment from unexpected overcurrent/overheating that can be caused by jams or breakdowns.

What is a Motor Starter?

A motor starter is a combination of devices used to start, run, and stop an induction motor based on commands from an operator or a controller. The motor starter must have at least two components to operate: a contactor to open or close the flow of energy to the motor, and an overload relay to protect the motor against thermal overload.

What is a Contactor?

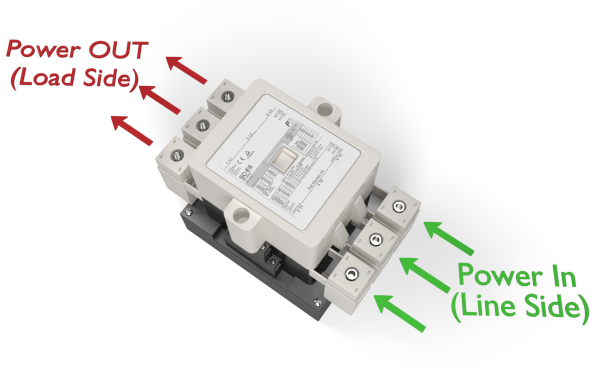

A contactor is a 3-pole electromechanical switch whose contacts are closed by applying voltage to a coil. When the coil is energized, the contacts are closed, and remain closed, until the coil is de-energized. Since a motor has inductance, breaking the current is more difficult so the contactor has both a horsepower and current rating that need to be adhered to.

The overload relay is a device that has three current sensing elements and protects the motor from an overcurrent. Each phase going from the contactor to the motor passes through an overload relay current-sensing element. If the overload current exceeds the setting of the relay for a sufficient length of time, a set of contacts opens to protect the motor from damage.

AC motor starter circuits can be controlled from simple pushbuttons or from remote signals such as from a PLC.

To learn more, check out the AC Motor On/Off Controls chapter in our Automation VIDEO Cookbook. Learn about the types of AC motors and basic control schemes.

“Tech Tip” videos start with an overview of AC motors and how to select the proper size based on system requirements. Other topics include:

- How to specify contactors

- Selecting overload protection

- Selecting circuit breakers

- How and why to use surge protection

- Setting up and using latching contactors

- How to use auxiliary contacts

- Reversing motors by using contactors

The “How To” videos show step-by-step how to wire and use programming logic with various types of motor control circuits, connecting to CLICK, Do-more or Productivity series PLCs.

To read more articles like this, click here.