What is an Arc Flash?

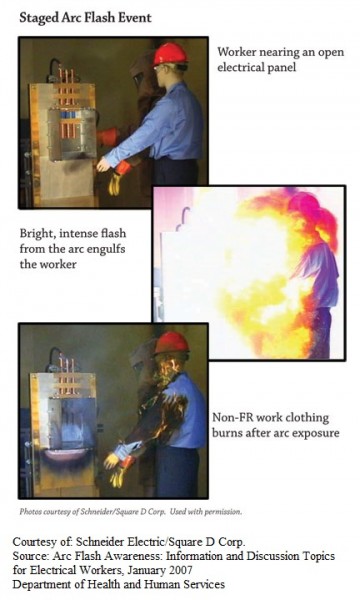

The subject of arc flash has become a major concern in electrical safety. What exactly is arc flash and how can it be prevented? Arc flash is high temperature conductive plasma formed when a short circuit fault occurs between at least two energized conductors. It occurs when a phase-to-phase fault or phase-to-ground fault causes energized conductors to go beyond their rated voltage and current limits. If the protective device allows this condition to happen, conductors will explode or “arc flash,” producing a flash of light, loud noise, and temperatures exceeding 5000° F. When this happens, hot gases are released and molten metal is projected outward from the fault area. An arc flash can happen in as little as 1/1000 of a second, creating a shock wave that can hurl loose items from the area outward. The shock wave produced from the instantaneous heating of air could be great enough to knock someone completely off their feet. Personnel standing in the area could be seriously injured with loss of sight, loss of hearing and severe burns; injuries can be severe enough to cause death.

Why Its Important

Even though arc flashing has existed for as long as electricity, why does this topic seem to be at the top of everyone’s list today? With the high demands on electrical energy in the industrial environment, arc flash accidents are increasing. Some reports indicate as many as 10 to 15 serious arc flash incidents happen each day in the United States. This is causing concern about personal safety in the event of an arc flash. Authorities have begun to rigorously investigate what an arc flash is and what causes it. The results provide a better understanding of arc flash, quantify its potential hazards, and encourage the adoption of safer work practices.

The Occupational Safety and Health Administration (OSHA) has been able to enforce safer workplace practices with their standards. When an accident has occurred due to an arc flash, OSHA is likely to cite the employer with non-compliance of 29CFR 1910.335(a)(1)(i) and 29CFR 1910.132(d)(1) which requires proper protective equipment usage and requires the employer to perform an assessment of workplace hazards. In 1976 the National Fire Protection Association (NFPA) formed a committee to write and publish their first workplace safety standard concerning electrical safety. In 2004 the NFPA 70E, “Standard for Electrical Safety in the Workplace”, was approved and adopted for use. Even though OSHA has not incorporated the NFPA 70E in the Code of Federal Regulations, they still use it as a “how to comply” manual. An employer is not mandated to comply with the NFPA 70E, but OSHA has been able to show that conforming to the standard helps maintain compliance with mandated OSHA regulations. OSHA contends that compliance with NFPA 70E can prevent or lessen the risk of injury and has been able to use this as a baseline to prove if an employer has acted reasonably.

The Occupational Safety and Health Administration (OSHA) has been able to enforce safer workplace practices with their standards. When an accident has occurred due to an arc flash, OSHA is likely to cite the employer with non-compliance of 29CFR 1910.335(a)(1)(i) and 29CFR 1910.132(d)(1) which requires proper protective equipment usage and requires the employer to perform an assessment of workplace hazards. In 1976 the National Fire Protection Association (NFPA) formed a committee to write and publish their first workplace safety standard concerning electrical safety. In 2004 the NFPA 70E, “Standard for Electrical Safety in the Workplace”, was approved and adopted for use. Even though OSHA has not incorporated the NFPA 70E in the Code of Federal Regulations, they still use it as a “how to comply” manual. An employer is not mandated to comply with the NFPA 70E, but OSHA has been able to show that conforming to the standard helps maintain compliance with mandated OSHA regulations. OSHA contends that compliance with NFPA 70E can prevent or lessen the risk of injury and has been able to use this as a baseline to prove if an employer has acted reasonably.

One method to minimize the magnitude of an arc flash and decrease the damages incurred involves the use of current limiting fuses. Current limiting fuses reduce the amount of thermal energy (I2t) produced during a fault.

In a current limiting fuse, the fusible link’s typical design has many places where the cross-sectional area has been reduced in size, and the link is usually encapsulated in quartz sand. When a short circuit fault occurs, the reduced cross-sectional areas on the fusible link will heat up quickly and melt, thus opening the fusible link. As the fusible link opens, clearing the fault, an arc will form across the opening. The quartz sand helps quench the arc, reducing the amount of time it takes to clear the fault. The sand also helps dissipate the heat generated during the fault condition. The link, which had a very low resistance before the fault, becomes a link with very high resistance. This significantly reduces the current in the short circuit.

Looking at the thermal energy let-through formula, I2t, “I” is the effective let-through current, squared, multiplied by “t”, which is the time it takes for the fuse to clear the fault. It is easy to see that the thermal energy will be greatly reduced if less current is available during the fault.

Looking at the thermal energy let-through formula, I2t, “I” is the effective let-through current, squared, multiplied by “t”, which is the time it takes for the fuse to clear the fault. It is easy to see that the thermal energy will be greatly reduced if less current is available during the fault.

Are current limiting fuses the best solution for arc flash hazards? Current limiting fuses can reduce the amount of thermal energy generated during a fault, but they do not eliminate it completely. An arc flash hazard is still present; it is just greatly reduced in magnitude. In many cases, even with reduced thermal energy, the arc flash can still cause serious injuries and damage.

NFPA 70E 110.8(B)(1)(b) states that a flash hazard analysis should be performed in order to protect personnel from the possibility of being injured by an arc flash. A flash hazard analysis will determine the required personal protective equipment (PPE), the boundaries and the approach limits. Article 130.3(A) defines the Flash protection boundary or approach limits, and Article 130(B) defines how to determine the proper personal protective equipment needed.

Most people who work around energized equipment are familiar with arc flashes; some have even seen it. However, an “it can’t happen to me” mentality often exists. An arc flash incident is a very serious situation and one that everyone working with live circuits must consider. While current limiting fuses can reduce the risk of an arc flash, they are not a substitute for a complete arc flash analysis. Working on energized equipment can be done as safely as possible, but ensuring safety includes knowing personnel are properly prepared for arc flash hazards and are aware of how to reduce this risk.

References

1) NFPA 70E, “Standard for electrical Safety in the Workplace,” 2004 edition

2) Occupational Safety and Health Standards 29CFR1910.335 “Safeguards for personal protection”

3) Occupational Safety and Health Standards 29CFR1910.132 “General Requirements”

By Jerry Reaves

AutomationDirect

Product Manager,

Power Distribution Components

Originally Published: June 1, 2008