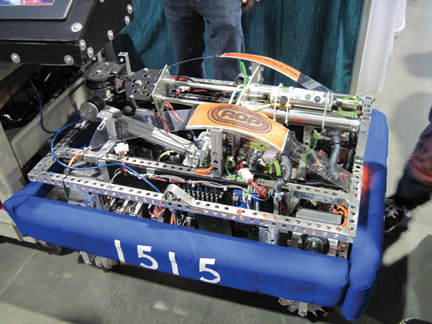

Alexander Kern is a member of the Beverley Hills High School MorTorq Robotics team. He contacted AutomationDirect in February of this year with questions about interfacing a C-more touch panel to his high school’s robot. In a few short weeks, Alex and his team built a robot from scratch, interfacing the C-more panel to operate the robot during competition, including several screens dedicated to various diagnostic functions required by the team.

In early March, Team 1515 traveled to a FIRST Robotics regional event in Portland Oregon, where the team won the Motorola Quality Award in part due to the innovative use of the touch screen interface. They went on to win the regional as part of a three-team alliance, and qualified for the World Championship event in Atlanta.

Less than a month later, the team attended the Los Angeles regional event, and won the Regional Chairman’s Award, the most prestigious award given in each region.

We sat down with Alex at the World Championships (April 15-17) and asked him a few questions:

Q: How did you become interested in robotics?

A: When I was around 11 years old, I attended a technology-based summer camp known as PlanetBravo. I took the robotics course and it got me really interested in the whole concept, especially the programming aspect. After experimenting with VeX for a couple of years, I was invited to join my high school’s robotics team when I was in eighth grade.

Q: What was your first robotics project?

A: For my first project, I built a little robot which pushed and kicked ping pong balls into miniature soccer goals. It could also track a black line on the ground using sensors underneath the robot.

Q: What is your favorite subject in high school?

A: Undoubtedly, my favorite subjects in school are Computer Science and Math. Being a programmer, I’ve always found computers to be intriguing and really enjoy both courses. Next year, I will be taking a combined Computer Science and Math Analysis class, which unlike most kids my age, I’m looking forward to.

Q: What are your plans after high school?

A: I plan on becoming an Internet entrepreneur, creating the next huge Web site like Facebook or Google. Networking and systems architecture has always been my specialty, and I hope to pursue it in my career.

Q: How does the C-more touch panel interface with the MorTorq Robot?

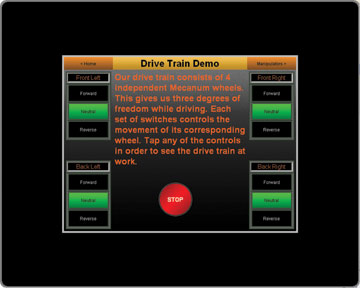

A: The touch panel controls all functions of the robot, including manual overrides for each of the robot’s Mecanum wheels and the pneumatic kicker. The touch panel first communicates via Modbus over TCP/IP into a DL06 PLC. The PLC’s digital outputs then control another set of relays which take the 24 volts supplied by the PLC and step it down to 5 volts. These relays then feed into a small USB Cypress Board, connected via USB to the laptop. The laptop communicates wirelessly with the robot’s onboard controller. We also have two-way feedback, which has a reverse signal flow.

Q: How similar was the final solution to the original plan?

A: The final solution of using a PLC and relays to communicate with the robot was absolutely nothing like what I had originally designed. We attempted to use an Arduino Mega instead of a PLC, in order to save space and battery, but the Arduino could not handle the fast poll times needed to control the robot during the game. We then chose to use a DL06 PLC from AutomationDirect. Once we started it up, however, the 24VDC from the PLC fried the USB Board instantly, forcing us to install relays to reduce the voltage.

Q: Why did you change this approach, and what did you learn?

A: While playing around with the Arduino and the touch panel, I became very familiar with the industry standard Modbus protocol, because I had to develop a software library which could both send and receive it. When implementing the relays, we ran into some difficulty with the difference between sourcing and sinking, but we’ll make sure that we never make that mistake again!

Q: You mentioned that your robot uses Mecanum wheels – as do many of the FIRST robots – can you briefly explain how they work?

A: A Mecanum wheel is a conventional wheel with a series of rollers attached to its circumference. Each roller has an axis of rotation that is 45° to the plane of the wheel and in a plane parallel to the axis of rotation of the wheel. As well as moving forward and backward like conventional wheels, they allow sideways movement by spinning the wheels of the front and rear axles in opposite directions. Vehicles with Mecanum wheels can move forward, backward, sideways, diagonally, turn about their axis, and perform various combinations of these movements at the same time.

Q: The MorTorq Robot has independent motors driving each of the four Mecanum wheels. What happens if one of these drive systems gets damaged during the competition?

A: Because of the nature of Mecanum wheels, the result of losing a driven wheel is a serious steering problem. If we lost a wheel, the robot would be nearly impossible to control due to the complex nature of the steering algorithm. One of the features we were able to implement with the touch screen was the ability to adapt for lost power at any wheel. With a simple touch of the screen, the algorithm is changed so that the three remaining wheels compensate by reducing or increasing their speed. The driver of the robot never notices a difference, aside from a slightly slower robot.

Q: Do you have plans to improve or reuse the application?

A: We do! In the future, we plan to use the exact same operator interface for the robots, each year adding to or improving its existing features. One of the benefits of using a touch panel over standard physical switches and buttons is that you’re able to completely change the interface without modifying any hardware. Aside from the actual software changing, we plan on outfitting the case with Lexan and lights to add an extra “wow” factor. Other modifications we are considering include alternative joysticks, another touch panel, and a smaller, more compact carrying case.

Learn more about FIRST Robotics at: http://www.usfirst.org/

Originally Published: June 1, 2010