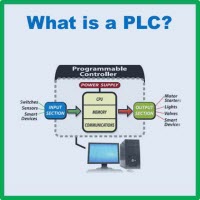

PLC Definition Programmable Logic Controllers (PLC) are often defined as miniature industrial computers that contain hardware and software used to perform control functions. More specifically, a PLC would be used for the automation of industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or food processing. They are designed for multiple…

The PLC or Programmable Logic Controller has revolutionized the automation industry. Today PLCs can be found in everything from factory equipment to vending machines, but prior to New Year’s Day 1968 the programmable controller didn’t even exist. Instead what existed was a unique set of challenges that needed a solution. In order to understand the…

What controls you? No, I’m not talking about your boss, your spouse or the government. Instead, think of your body as an industrial control system. Now, what controls you? Hopefully, you said your brain, although the heart is an acceptable answer sometimes. But for now, let’s focus on the brain and the nervous system as…

One of the biggest factors in any PLC buying decision is the capability of the programming software. How easy is it to use? What does it offer? PLC hardware is only half of the equation, and who wants to buy a controller only to find out the software is lacking the basics? No thanks! So,…

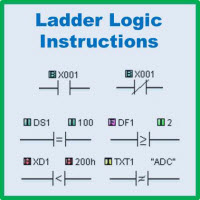

In Understanding Ladder Logic we touched on the origins of Ladder Logic, its structure and execution. So now that we have a understanding of what Ladder Logic is, we can dig a little deeper into how ladder instructions work. And to do that, we need to first understand Boolean math and logic gates. Now, this blog…

+Tech TopicsDiscrete SensingeBookLearning ResourcesMotorsOnline OnlyPLC eBookProcess Sensing & ControlProductProgrammable Control

Ladder Logic in Action

Ladder logic programming for industrial controllers has evolved significantly over the years, and now supports advanced functionality such as process control, motion control, data manipulation, networking, and data acquisition. However, when you start with a blank page to design a new control system, large or small, there are many basic functions this tried-and-true language is…

Lock your doors, board up the windows, and prepare yourself for a deeper look into PID loops! Now, if you are still here, great! If you ran out of the room screaming like I did, you can catch up later. For some, PID loops can be scary. After all, they are pretty complex and involve…

+Tech TopicsCommunicationsCommunications and EtherneteBookethernet explosionLearning ResourcesOnline OnlyPLC eBookProductProgrammable Control

PLC Communications - Coming of Age

PLC communications has grown and changed over the many years since the controller’s inception decades ago. Industrial needs and technological advances have kept PLC communications evolving, and this post will explore some past and present communication standards, and what the future may hold. PLC Partners in Communications PLCs need to communicate to a number of different…

+Tech TopicsCommunications and Ethernetethernet explosionLearning ResourcesOnline OnlyPLC eBookProductProgrammable Control

EtherNet/IP: Implicit vs. Explicit Messaging

Over the years, Ethernet/IP has grown into an impressive industrial Ethernet communication network for connecting automation equipment, processes and machines. Keys to its success are the network and transport layers where explicit and implicit messaging takes place; here’s how to use these features to optimize your EtherNet/IP networks. Please refer to the Table and Diagram…

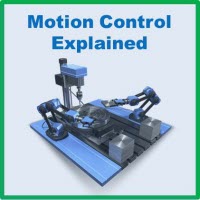

Motion control is generally understood to mean the use of servo and/or stepper systems as the “muscle” to move a given load. These motion control systems are capable of extremely precise speed, position, and torque control. Applications which require positioning of product, synchronization of separate elements, or rapid start/stop motion are all perfect candidates for…