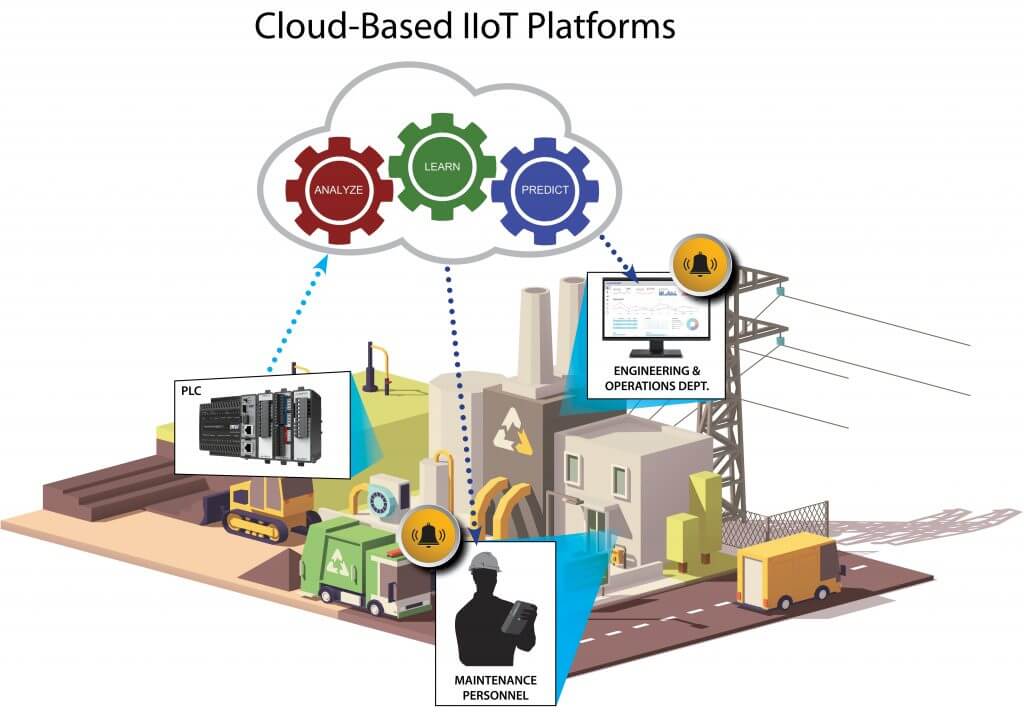

PLCs can now be directly integrated with cloud-based computing platforms, empowering end users and OEMs to quickly and easily add IIoT functionality to their systems.

Damon Purvis, PLC Product Manager at AutomationDirect, wrote an article for the August 2021 edition of Machine Design. The article is titled Modern PLCs Simplify Cloud-Based IIoT and it talks about how the newest BRX PLCs can securely connect directly to the leading cloud platforms from AWS, Microsoft, and others.

Industrial automation systems created by end users and OEMs have long had some IIoT data connectivity capabilities—but getting to this data and working with it has often been a chore, prohibitively expensive, or both.

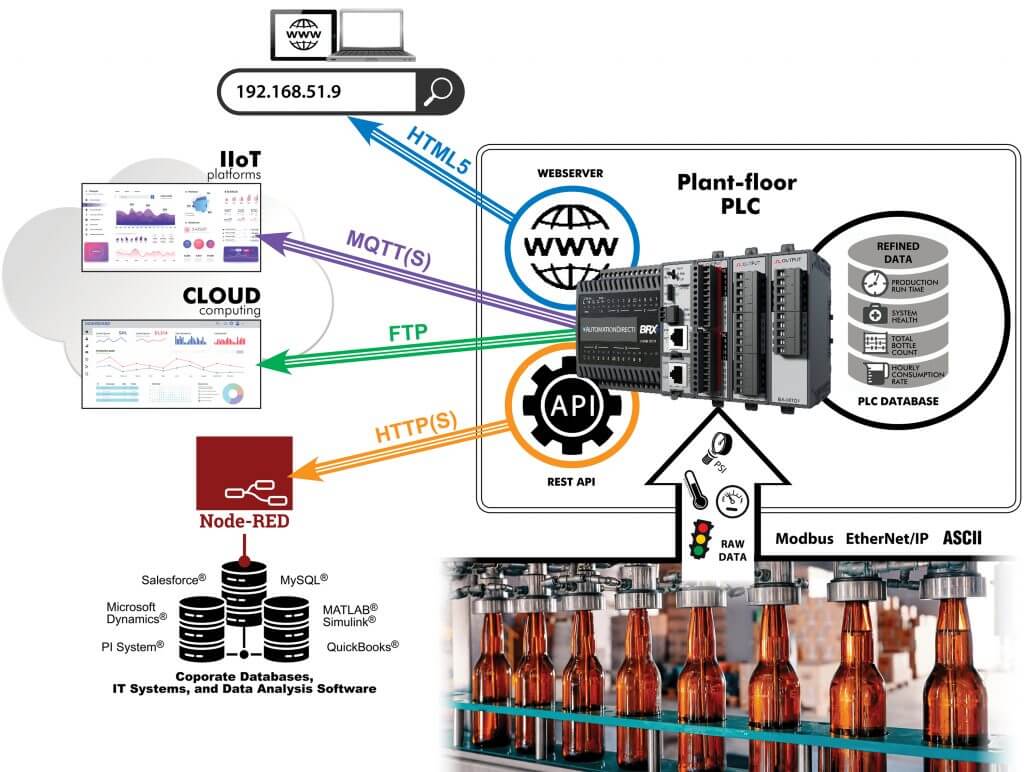

Cloud computing options have eliminated many of these barriers, providing a cost-effective way to deploy and scale up IIoT projects. This is especially the case now that the BRX PLC can connect natively to cloud services, without requiring intermediate layers of processing.

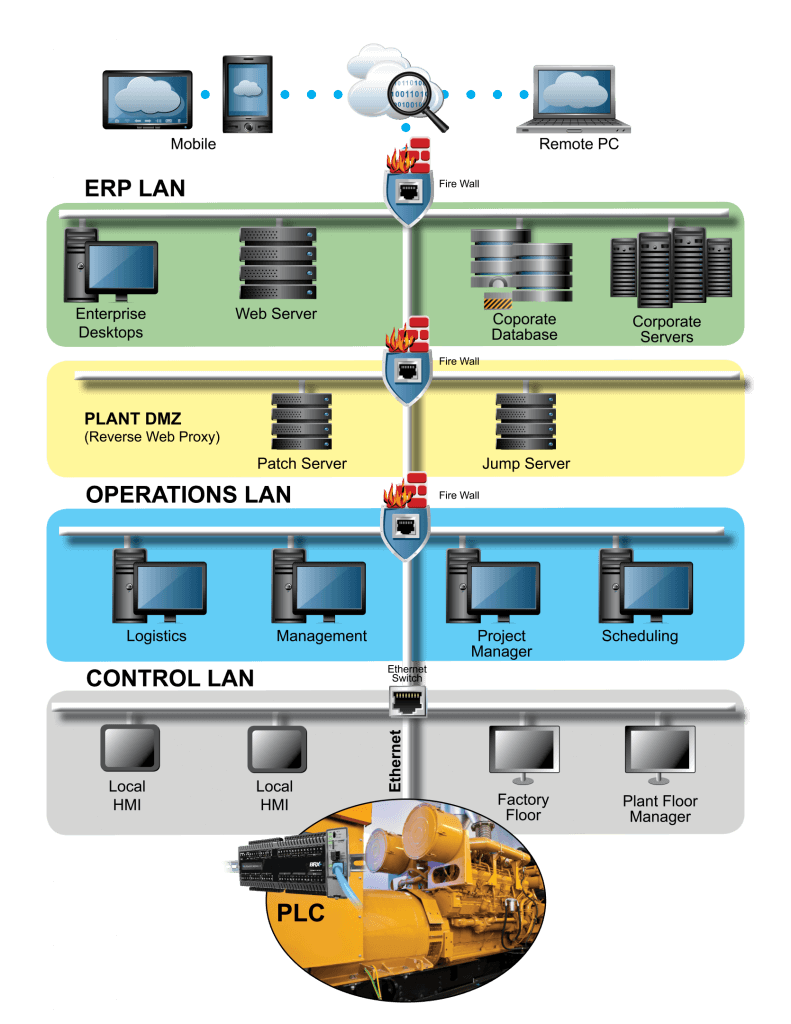

Cybersecurity is a Top Priority

As you might expect, connecting a PLC to the internet and cloud services raises some cybersecurity red flags. The major cloud computing providers—Microsoft Azure, Amazon Web Services (AWS), and Google—are acutely aware of the need for security and therefore incorporate:

- Software development kits (SDKs) for enforcing proper authentication.

- MQTT over transport layer security (TLS) for secure data transport.

- Secure hypertext transfer protocol (HTTPS) for secure web services when pushing/pulling data.

Better Availability

Many users might be concerned with the availability of cloud computing and would not be capable of creating an always-on and cybersecure solution from the ground up. This is where established cloud platforms shine because their infrastructure designs already replicate data to different regions, while incorporating server redundancy to stay operational in the case of trouble.

Super Scalability

Incrementally incorporating modern PLCs with cloud computing services is a great way to try out an IIoT concept and then scale it up as needed. The BRX PLC can aggregate, calculate, and create structured data and associated context—also known as metadata—and then seamlessly send it to the cloud. Users can start small in the cloud by selecting and refining the services they require, and grow these resources as needed. This approach also serves to bridge the traditional divide between OT personnel at the manufacturing site and IT personnel at the enterprise level.

More Advantages

Industrial automation end users can realize many benefits from cloud-based IIoT deployments, and there are even more advantages for machine and equipment builders.

These OEMs can provide new equipment with an all-in-one PLC for local machine control, along with direct connectivity to the cloud. Some PLCs include multiple Ethernet ports so OEMs can establish one network segment for local machine connections, and a second for cloud/internet connectivity.

Off-the-shelf PLCs and cloud services enable OEMs to easily design, build, and deploy advanced software-as-a-service (SaaS) applications for machine performance, monitoring, data logging, and more.

Modern cloud-capable PLCs remove the burden of learning and experimenting with connectivity options, allowing end users and OEMs can focus on their core strengths, while still taking advantage of the latest IIoT technologies and accompanying benefits.