OEMs making pneumatic machinery are delivering greater value to their end users by integrating smart solenoid manifolds and cloud-capable PLCs.

Kevin Kakascik, Technical Marketing Engineer with AutomationDirect, wrote an article for the November 2021 issue of Hydraulics & Pneumatics titled The Age of Intelligent Pneumatics. It shows how OEMs can use intelligent solenoid manifolds and modern PLCs to add valuable industrial internet of things (IIoT) capability to equipment.

While equipment must always run safely, efficiently, and reliably, many end users are demanding IIoT connectivity as a must-have feature. On both new and existing equipment, these increasingly sophisticated users want the visualization, data access, and analytical capabilities that IIoT technologies facilitate.

More Data

New controller and intelligent field device technologies are making more data available. This can include sensor and status information, derived values such as alarm signals and cycle counts, and other diagnostics. Visualization on an HMI or mobile app is the most basic use for this data, but the information can also be logged for reporting purposes and deeper analysis.

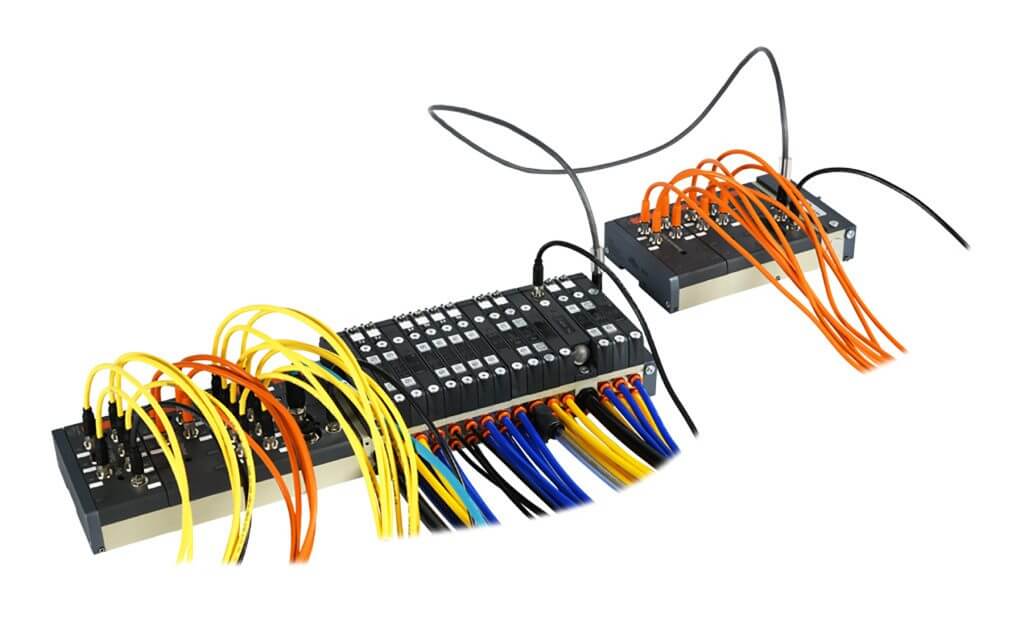

Many Signals

Some signals may come from field devices and sensors already wired to traditional controller I/O. Newer smart devices, like variable speed drives (VFDs) and modular pneumatic solenoid valve systems offered by AutomationDirect can use I/O or provide on-board communication with common industrial protocols like EtherNet/IP. This latter direct communication method provides more data options, reduces wiring, and enables distribution of the smart devices in an organized manner on the automated machine or system.

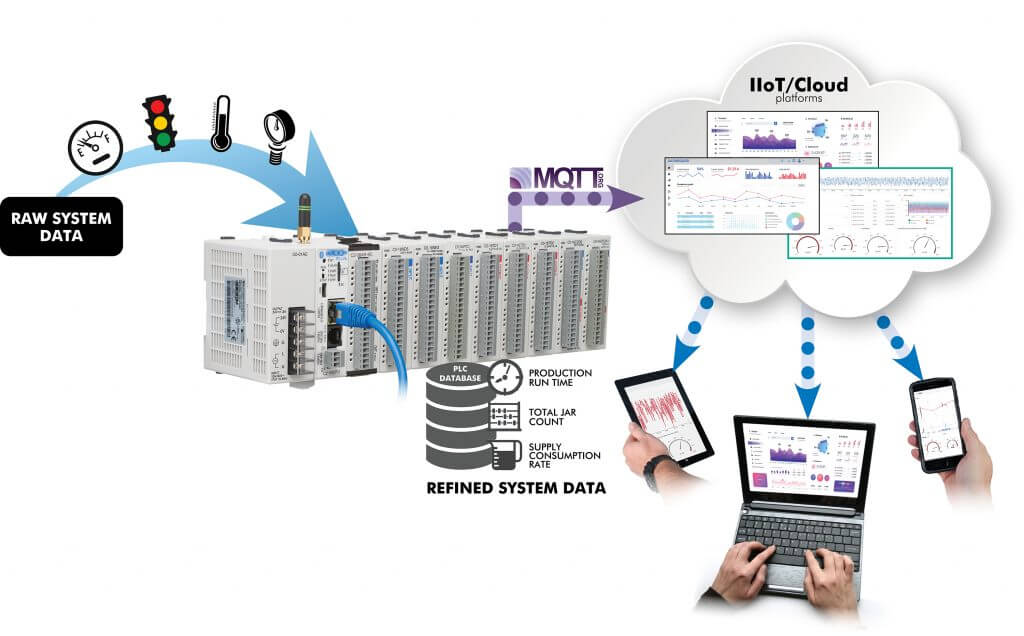

PLCs Connect to the Cloud

Regardless of how PLCs obtain field data, it used to require a little more hardware, software, and legwork to bump it up to higher-level systems.

However, the most modern PLCs now have what it takes to enable field-to-cloud connectivity in a more streamlined manner. PLCs are already ideal for the operating environment because they are built robustly and have many I/O and industrial field bus options.

Most AutomationDirect PLCs can use wired Ethernet, Wi-Fi, and/or Bluetooth for easy installation, configuration, and connectivity. In particular, the introduction of the IT-friendly MQTT protocol in recent years has made it simple and efficient to send data to the cloud.

IIoT-Enabled equipment

OEMs are taking advantage of PLC and intelligent device developments to add valuable IIoT capabilities to their equipment. The portfolio of products offered by AutomationDirect is a flexible, modular, and scalable way for end users to get started.