IoT cloud connectivity lets experts effectively support increasingly complex HVAC systems, such as refrigerant-side economizers for data centers.

Robbie Hyde, owner of Interface Mechanics LLC, wrote a success story article for the July 2022 online version of Smart Industry titled Cloud-Based IoT Supports Complex Control Systems from Anywhere. Here’s a summary, click on the link above for the full text.

For data centers powering the internet, the energy used to keep these systems cool is often the greatest operating cost, so small efficiency improvements can result in significant savings. Refrigeration methods have become sophisticated, and in many cases have outpaced the mechanical, electrical, and software skills of on-site operations and maintenance staff. In 2010, Hyde founded Interface Mechanics to provide local and remote systems integration (SI) services for high-tech HVAC systems using modern controller and cloud interface technologies.

Modern Chill

Commercial HVAC applications often use an add-on feature called an economizer. If it is cool enough outside, an air-side economizer can use ambient air to directly cool the interior of a building without running compressors, offering massive energy savings. More recently, data centers have been designed with chiller refrigerant-side economizers, which have more complicated mechanics but can lower energy costs to one tenth as compared to traditional methods.

Keeping Tech Comprehensible

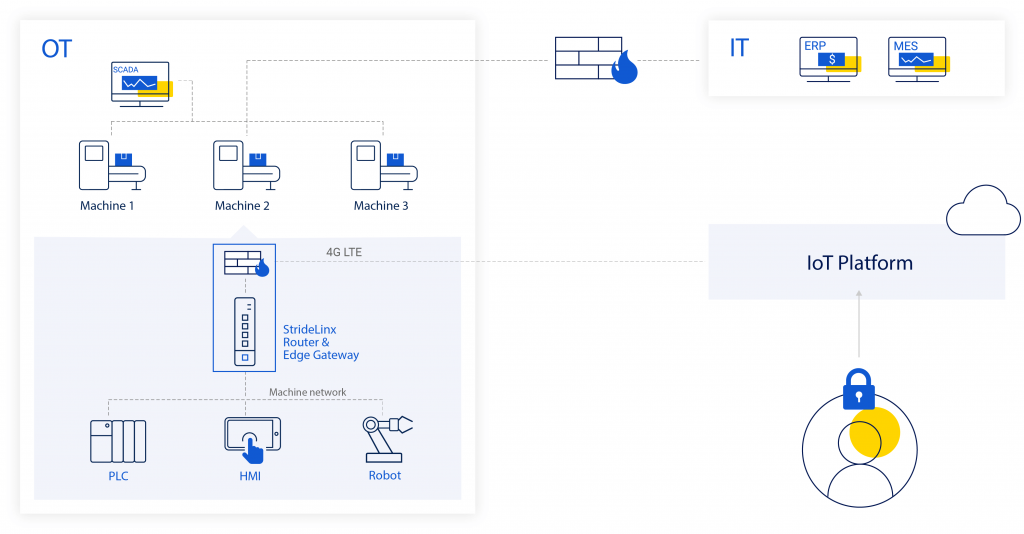

End user clients loved the refrigerant-side economizer energy savings, but technicians and general SIs had difficulty supporting them due to the automation complexity surrounding the advanced physics. Interface Mechanics began developing a way to make OT data available to an IT infrastructure, providing secure connectivity and visibility via an IIoT cloud solution, so they could effectively support their clients.

Cool Connections

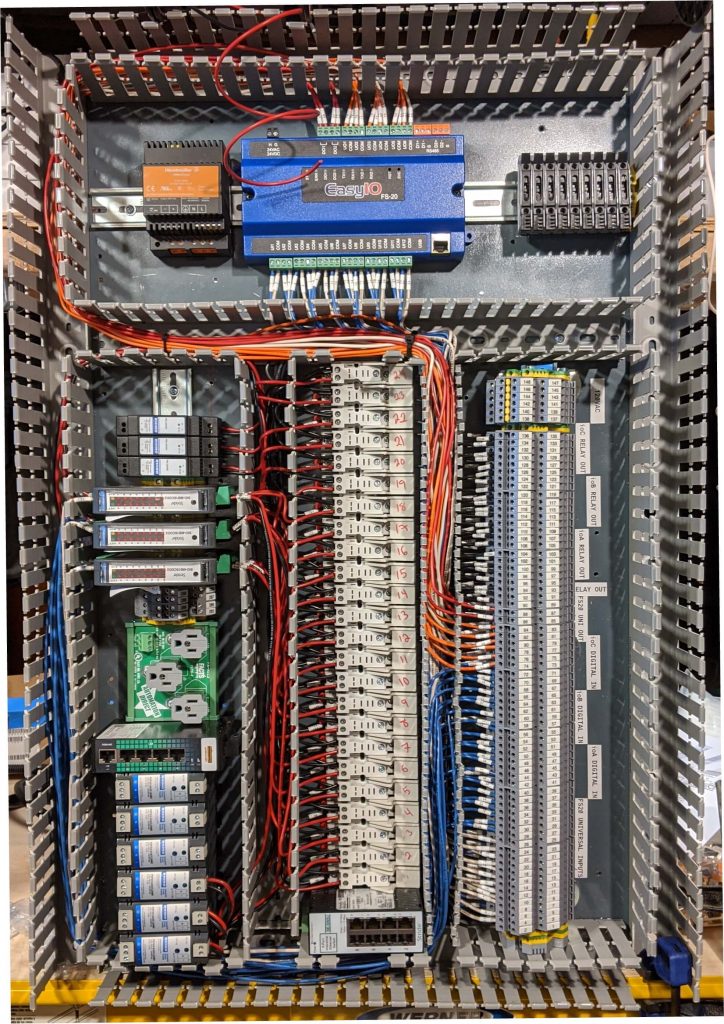

Interface Mechanics used AutomationDirect StrideLinx VPN routers, terminal blocks, power supplies, and other components to create a standard local control panel flexible enough to connect with PLCs, proprietary controllers, and field instruments of all types.

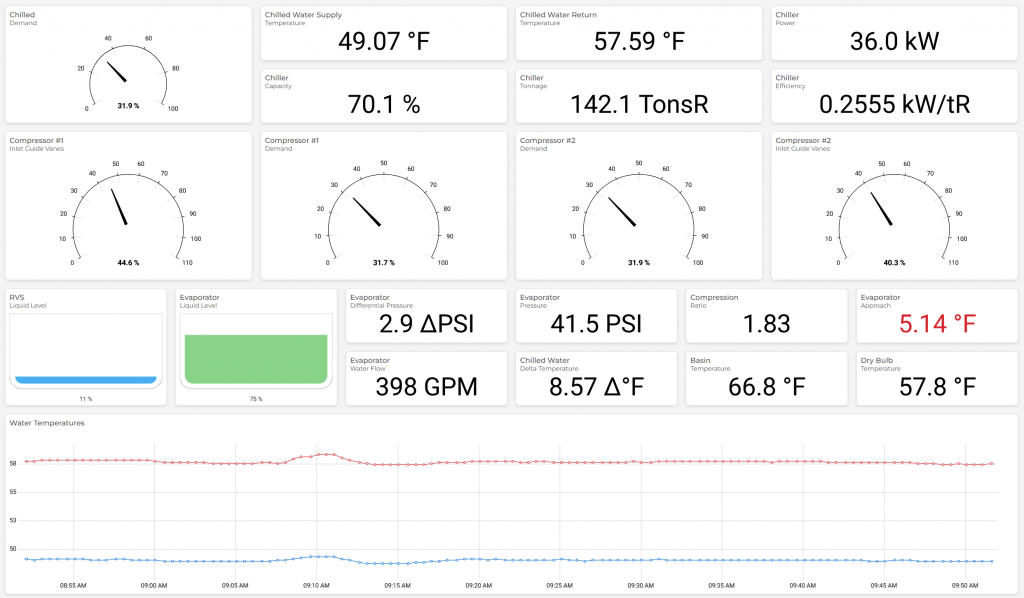

In conjunction with a Raspberry Pi controller running Node-RED, this system provides the necessary data handling and processing to operate mobile apps used for live dashboarding.

Interface Mechanics has branded the resulting solution, with associated Android and iOS apps, as LogBus , and has placed it in service at many sites to support all types of HVAC elements, including boilers. Authorized end users, the Interface Mechanics team, OEMs, and SIs can now remotely and securely access and monitor their equipment, and even make changes as needed.

This cloud-capable IoT platform makes it practical for modern—and sometimes complex—technologies to be deployed anywhere, and then successfully supported, regardless of what local staff is available. In many cases, remote monitoring can predict problems before they happen, providing the information required for proactive maintenance. Cloud connectivity lets support experts from around the world effectively and securely work on these systems, supplementing local staff as required, or providing complete support if desired by the customer.

All figures courtesy of Interface Mechanics