Earl Bouse, with E. Larue Enterprises in Dahlonega, GA., has been developing his idea of the “perfect” automated basketball defender for the last two and a half years. Although Bouse says that his DaMan creation is not quite ready for prime time, he is ready for prospective customer feedback and field tests.

With the 75th Final Four happening “just down the street” in Atlanta this year, Bouse took advantage of the opportunity to debut his creation to the basketball world by participating in the NABC (National Association of Basketball Coaches) convention. Coaches and players alike were given the opportunity to experience what it’s like to be the “Big Man” on the court.

Another exciting event for DaMan was an audition for the popular TV show Shark Tank which took place at Atlanta’s historic Fox Theater. Even if they don’t make the show, they were an overwhelming favorite of other co-inventors and local TV stations which aired several interviews asking the big question, “Is DaMan the next Million Dollar invention?” Bouse certainly hopes so.

What exactly is DaMan?

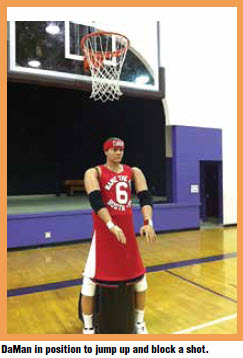

It’s best described as a mobile, anthropomorphic, robotic, athletic defender. The original concept was to design and develop a more efficient and user friendly basketball defender/shot blocker. But with input from several coaches, players and others who have seen DaMan in action, Bouse says, “We see other opportunities like volleyball and possibly even baseball in his future.”

Functionally, DaMan is a three-dimensional device which can raise and lower his arms, vary his body height from 6’7” to 8’7” and rotate his body a full 180 degrees. DaMan is mobile, which enables him to go forward while rising up as a “closing leaping defender” as well as go backwards and sideways.

Not only is DaMan a mover and a shaker, he also has the ability to “talk a little trash” via a headset worn by the coach, which broadcasts his voice through a speaker mounted in the DaMan’s chest (e.g. “Not in my house Son!”).

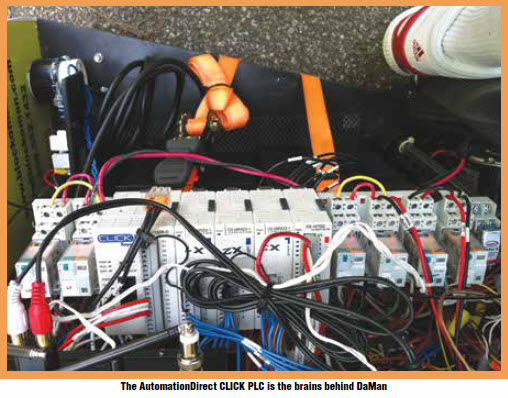

The key to all this movement is five motors controlled via an AutomationDirect CLICK PLC, which enables DaMan to be operated in any one of three operational modes:

1). Radio control whereby he is controlled by a custom wireless radio transmitter

2). Sensor mode which reacts to sonic range sensor inputs, and

3). Autonomously to a scripted PLC program which enables DaMan to follow a reflective tape using input from AutomationDirect reflective photoelectric sensors and respond accordingly.

The CLICK automation controller was the “tool of choice” for Dan Formella, their programmer and former Lanier Technology graduate. Bouse said that Dan’s familiarity made using the CLICK PLC a “no brainer” because of its low cost, I/O modularity and zero license fee!

The fact is that almost all the electronics, including relays, switches, indicator lights, ON/OFF, mode and limit switches are sourced from AutomationDirect.

Field tests are scheduled for this summer and fall with customer availability expected next spring. Bouse said the company is also considering a partially assembled version that would be targeted to both technical and non-technical high school and college students. This would introduce them to robotics and broaden their interest in sport activities as well. As students learn how to program the CLICK PLC, the potential is limitless. You can be assured that students will expand the possibilities; we are just beginning to explore the options.

by Rick Folea

AutomationDirect

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Posted: Sept. 9, 2013