KCC Software fuels the safe and reliable upgrade of a highly flammable, corrosive and toxic gas distribution system for semiconductor tools.

A semiconductor manufacturer of memory and drive head technologies, Headway Technologies in Milpitas, California is a part of the TDK group of companies, the largest independent recording head supplier in the disk drive industry. Headway designs and manufacturers recording heads for high-performance hard disk drives.

Headway Technologies could no longer tolerate production interruptions, and its first step in the solution process was to contact KCC Software, an experienced system integrator with clients in over 27 states,to upgrade its automatic gas control (AGC) system.

In his May 2017 NASA Tech Briefs Automation System Manages Critical Gas Distribution Process article, Scott Martin, owner of KCC Software explains how his company upgraded Headway’s aging AGC system. Martin made his passion for supporting U.S.-based manufacturers clear as he describes how he used an AutomationDirect Do-more PLC and over twenty years of experience in steel, textile and automotive industry to upgrade a portion of Headway Technologies’ manufacturing process.

A semiconductor manufacturer of memory and drive head technologies, Headway Technologies in Milpitas, California is a part of the TDK group of companies, the largest independent recording head supplier in the disk drive industry. Headway designs and manufacturers recording heads for high-performance hard disk drives.

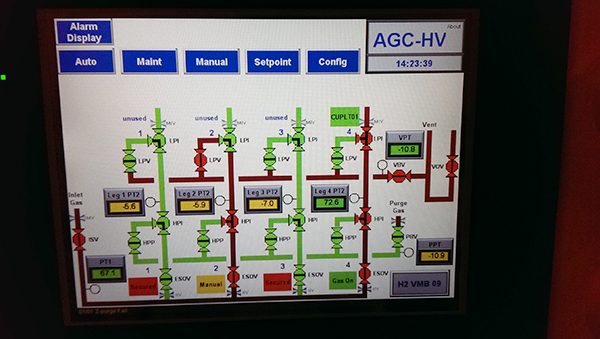

“In Headway’s manufacturing processes, industrial gases are used extensively due to the cleanliness demands of their high-density semiconductor products,” says Martin in the NASA Tech Briefs article. “A valve-manifold box (VMB) distributes gas from a single supply point to up to eight production tools (Figure 1).”

Figure 1

“As the gas is distributed through multiple legs, with one leg per process tool, the gas pressure is monitored constantly at multiple points”, continues Martin in the article. “Many of these gases are highly toxic, corrosive and/or flammable,” he says. “The VMB not only monitors gas delivery, but also provides multiple purge and maintenance functions when the gas manifolds, gas delivery legs or components need to be maintained or replaced.”

Safely Purge the Process

Under normal operation, the gas delivery system is active most of the time. The AGV system insures adequate gas flow and pressure are maintained by monitoring up to five gas pressure transducers and several gas flow switches. Gas pressure is monitored continuously, and any pressure out of limit conditions must be responded to immediately. A depleted supply or possible leak are indicated by a decrease in pressure, and closure of manual valves or blockages often cause an increase in pressure.

A purge sequence is executed during maintenance of valves, regulators and transducers when the AGC system is not active. “As many of these gases are toxic, flammable or both—a very detailed purge routine is required to first insure all process gas is removed from the lines,” points out Martin in the article. “A purge process can take hours to ensure all gasses have been evacuated.”

When starting back up after maintenance work, the gas lines must be free of contaminants, so a similar purge process must run. Once the gas lines are purged and clear of contaminates, gas can be reintroduced while the control system carefully monitors all flow and pressure transducers to ensure they are within the defined operating parameters.

These purge and monitoring routines are where the control system automation is critical. “These detailed purge routines and procedures create the greatest demand for an AGC system,” notes Martin in the NASA Tech Briefs article. “Gas delivery alone could be accomplished in a manual or semi-automatic fashion. However, to provide the greatest safety for the equipment and personnel involved in the maintenance of the equipment, the AGC and VMB, with advanced controller and automatic functions, is the route most manufacturers prefer.”

Upgrading the Controllers

Seven VMBs are located throughout the clean rooms near production equipment at Headway Technologies’ facility. The process control equipment continually monitors several gas leg-specific and general alarm conditions including leg high pressure, excess flow, high temperatures, jacket leaks, leg emergency gas off—along with seismic, smoke and fire detector status. Many other critical parameters are monitored including high, high/high and low delivery pressures

“Due to a series of large power spikes, many of the AutomationDirect DL205 WinPLC CPUs in the plant were damaged, although the I/O for these PLCs remained intact,” explains Martin. “As a result of CPU failures due to power spikes, and AutomationDirect’s announcement in 2015 that the CPU was no longer recommended for new installations, Headway Technologies decided to upgrade the automation controllers. Since KCC designed and developed the program for the original system, it was contacted to assist with the upgrade.”

An Experienced Integrator

Specializing in PLC, PC and database integration, KCC Software, a system integrator in Huntsville, Alabama, has been in business for over 20 years. Typical clients include larger engineering firms with a wide variety of mechanical and electrical skills but little automation design and programming capabilities. On other projects KCC works directly with an end user, such as with Headway on this project.

KCC Software was familiar with the original AGC and VMB systems, so Headway Technologies selected them for this new integration project. AutomationDirect PLCs were also in use at the facility, and KCC has developed and installed dozens of systems using these PLCs. As an AutomationDirect SI Direct system integrator, KCC partners with AutomationDirect in many industries that KCC serves including semiconductor, automotive, steel and textile.

“After reviewing the situation at Headway, KCC recommended the existing automation system be retrofitted with a new AutomationDirect Do-more H2 Series Programmable Logic Controller CPU,” relates Martin in the article. “Selecting this newer PLC CPU provided Headway Technologies with a system offering 10-years plus of service and support. Costs were minimized because of the low price of the new CPU, and because the new CPU was able to work with the existing I/O (Figure 2).”

Figure 2

The mechanical components of the VMBs were still in great shape, so there was no need to replace them, continued Martin. “But in addition to the PLC CPU, the existing 12-year-old HMI had to be replaced as well because it did not have a driver for communications with the new CPU,” he says in the article. “Replacing the existing HMI would simplify integration with the CPU, and would allow for addition of new features, along with extending service and support.”

The new PLC works with the installed, original AutomationDirect DirectLOGIC DL205 hardware. This backward compatibility made the CPU hardware upgrade simple and cost-effective since no I/O modules needed to be changed. All wiring remained intact, which shortened the time required to complete the project.

Control of Gas Delivery

“In addition to the PLC and the HMI, the AGC automation system includes existing 32-point and 16-point discrete output modules, and an 8-point relay module. It also includes a 16-point discrete input module, a 32-point discrete input module, and two 8-channel analog input modules. All I/O modules are mounted in a 9-slot base with the CPU” explains Martin in the NASA Tech Briefs article.

KCC developed and programmed five modes of user interaction in the AGC automation system: configuration, setpoint, manual, maintenance and auto.

“Due to safety concerns, a high level of password protection and security is provided for all five modes of user interaction,” points out Martin in the article. “Entry into any mode of operation requires a password. The AGC operates on three password-protected access levels: operator, maintenance and engineering. Operator access allows auto mode functions only. Maintenance access allows all modes except for configuration. Engineering access allows all modes of operation.”

The AGC system can distribute a wide variety of specialty gasses, so a configuration mode is needed to select gas options and define operating ranges of the pressure and flow transducers. The options and ranges are selectable via several HMI screens. The setpoint mode provides access to additional operating parameters such as valve open times during purge and vent cycles, and the number of cycles, which are adjusted depending on the type of gas used.

“Considering the differences between ammonia and argon for example, a purge control page allows the user to define the nature of the purge and the vent controls used,” explains Martin in the article. “Only a trained user with password access is able to use the manual mode to open and close valves.”

Functions and management tools required to maintain the VMB cabinet are available when in maintenance mode. Purge and evacuation functions are a big part of this. Auto mode is the normal operating mode when delivering gas.

Do-more Process Control Results

“KCC developed the new PLC and HMI software applications, and installed the new hardware and software at Headway Technologies’ facility in March of 2016,” relates Martin. “The new application was tested and verified in less than three days, with Headway’s equipment and maintenance staff assisting in the verification of the new system. The ease of working with Headway’s team quickly led to a functional and successful project.”

The first three AGC systems at Headway Technologies have been completed and the customer is extremely happy. The difficult and critical purge functions were carefully duplicated and work well. The new HMI screens that KCC created added additional capabilities for improved management of the VME processes. The screens were also easier to read and more attractive than the old ones.

“Headway has scheduled the purchase of the necessary hardware to run the same applications on four more VMBs, and KCC will assist with these upgrades as required,” notes Martin in the article. “Headway has also asked KCC to quote similar upgrades to non-VMB systems running at their facility. Headway is already discussing an IT upgrade to their facility to make good use of the AutomationDirect C-more HMI’s capability to send emails at critical points in the process. This would allow the maintenance staff to respond in a timely manner while still being able to perform other work during lengthy purge processes.”

The process improvements were completed with minimal downtime and at a reasonable cost, and the upgrades were a great success for both KCC and Headway.

*Originally published: April 17, 2018