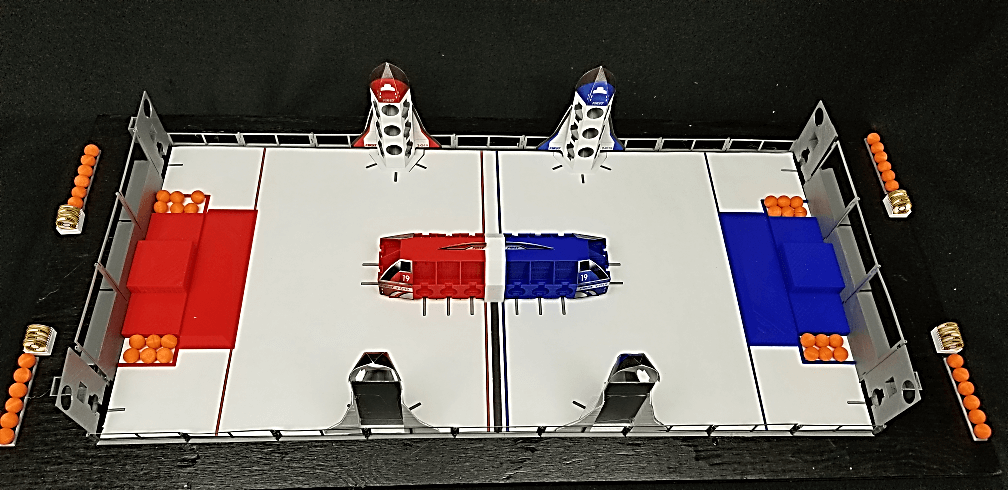

1:20th Scale Model of the 2019 Field

AutomationDirect’s animation team converted the animation models into 3D printable models for you to play with. This is the “playing field” for the FIRST Robotics Competition game for 2019. For more info about FIRST and the 2019 game: “DESTINATION: DEEP SPACE” – please visit the FIRST website.

Printable Scale Model of the DESTINATION: DEEP SPACE Field – 2019 FIRST Robotics Competition

>>>> CLICK HERE to download the game specific models (SolidWorks and STL files)

>>>> New CARGO File – Try this if the original doesn’t work

>>>> Click Here to download the Floor Mat, Hatch Panels, Decals

>>>> Click here to download the generic parts used each year

These models are NOT intended to be accurate representations of the actual field – please do not use them for ANY game, rule or ‘build’ decisions. These models have been highly modified from the actual field drawings to make them easy to 3D print and assemble and to give the general appearance of the actual POWER UP field. To paraphrase from the Latin – Caveat Printor! – Let the printer beware!

All parts should fit together, but that depends heavily on your printer accuracy. Hopefully, they are close enough that you can file things down a little if needed. The examples shown here were all printed on an inexpensive, low-end RepRap 3D Printer – so any printer you have should be able to print at least as well.

NOTE: We are NOT CAD experts, so if you see ways to improve these PLEASE do so and send us a copy – we will add it to the library. Let’s make this a community project!

Print settings we used for all items:

- 0.2mm layers

- Shell .4mm

- Top and bottom .4mm

- Fill 20% – you may want to print some of the thinner parts at 100% fill

- PLA: extruder 190, bed 60

- No supports (except the Loading Station)

While we have your attention

Have you used your AutomationDirect $35 Kit-Of-Parts Voucher yet? You know – for the real-world robot! If not, have your lead mentor log on to the FIRSTinspires dashboard to get your team’s voucher code – THEN follow these simple (BUT IMPORTANT) instructions to activate and use your voucher. We’ve got thousands of parts that can be used to help build your ‘bot. Check that link for a list of products that are popular with FIRST teams.

Assembly Instructions:

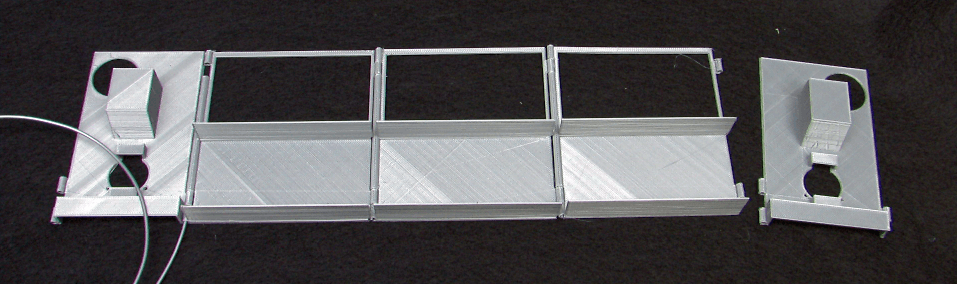

Field Perimeter Assembly

Print the following items:

Qty Item

6 Driver Stations – face down

2 Left Loading Stations – face down with supports

2 Right Loading Stations – face down with supports

18 Side Rails – face down

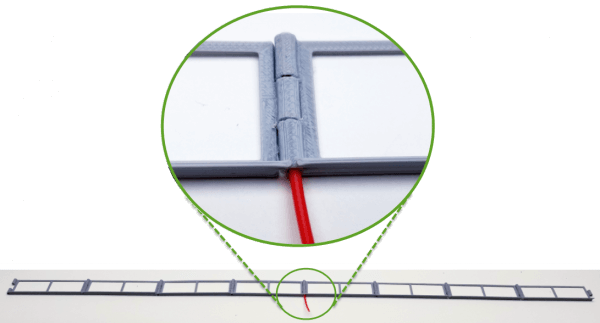

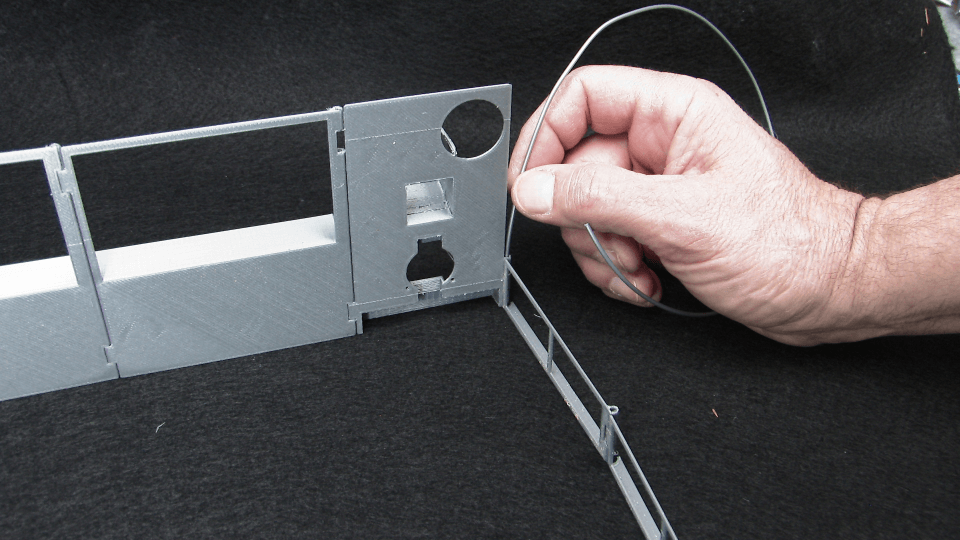

Step 1: Assemble Two Driver Station walls face down using 1.75mm filament as pins:

Power UP Driver Station Assembly

Insert enough filament to span the hinges (don’t need to go all the way up the wall). Trim excess filament off. No need to glue it in place.

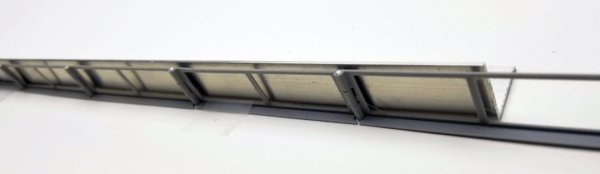

Assemble side rails using the same technique:

POWER UP Side Rail Assembly

Insert final pins between portals and side rails:

Perimeter Assembly

Use a straight edge to align side rails and tape or glue side rails to surface (angle aluminum works well for aligning the rails and hot glue works well for securing it to the surface):

POWER UP Side Rail Alignment

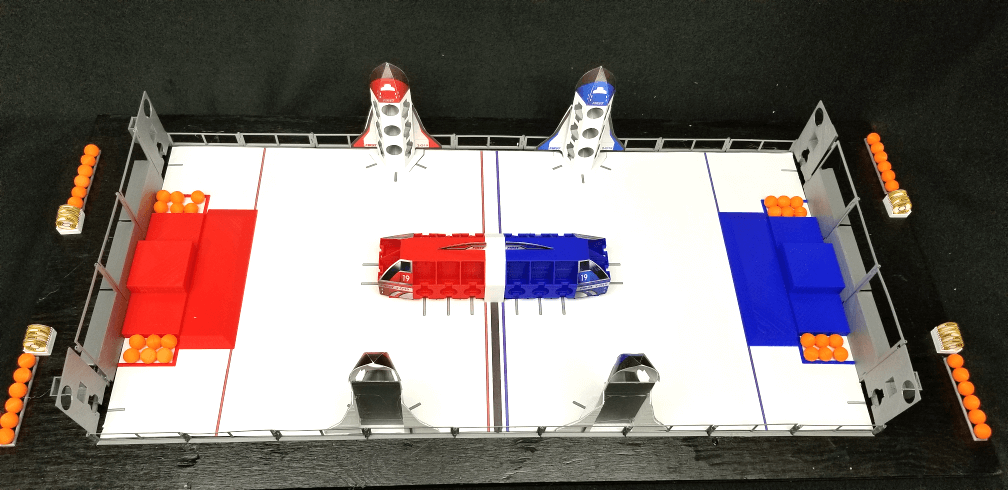

Add Alliance Station Walls and game elements:

POWER UP Field Perimeter

Habitat Assembly

Print the following items:

Qty Item

2 Habitats, 1 RED, 1 BLUE.

2 RED Depots 2 BLUE Depots

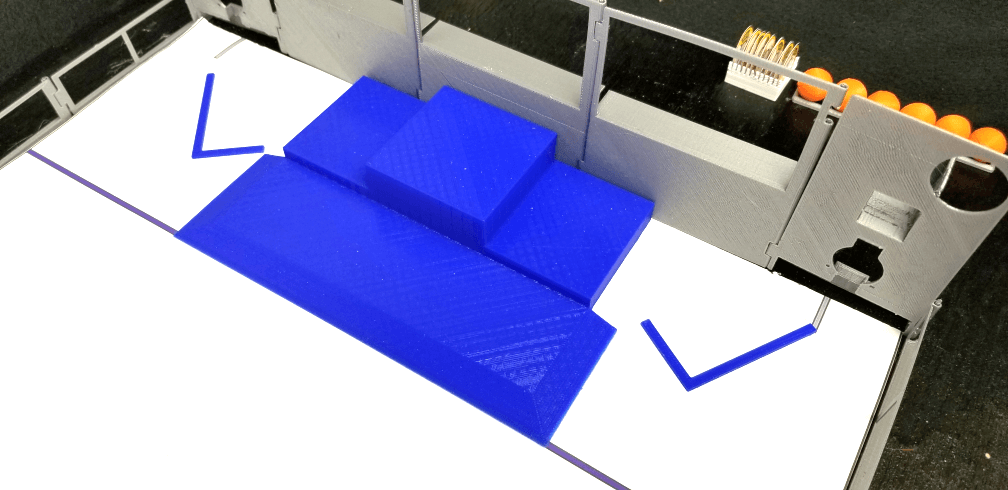

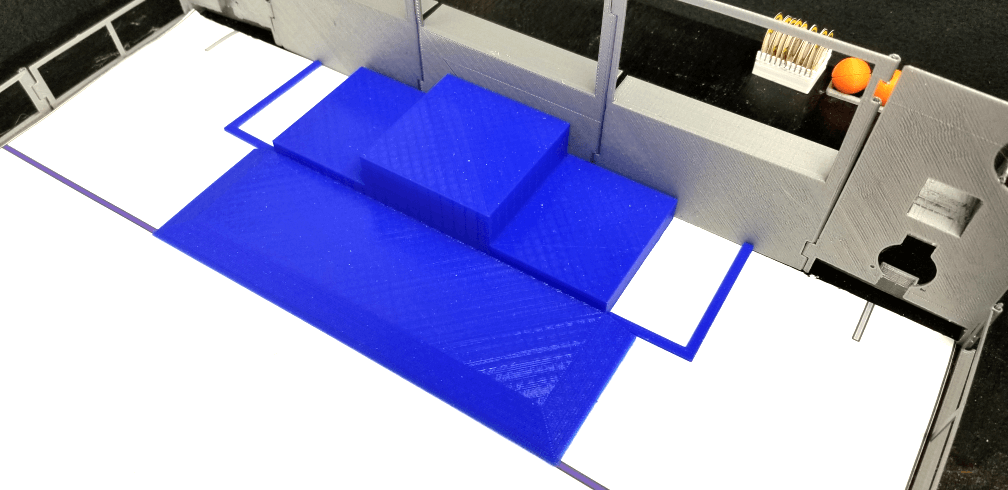

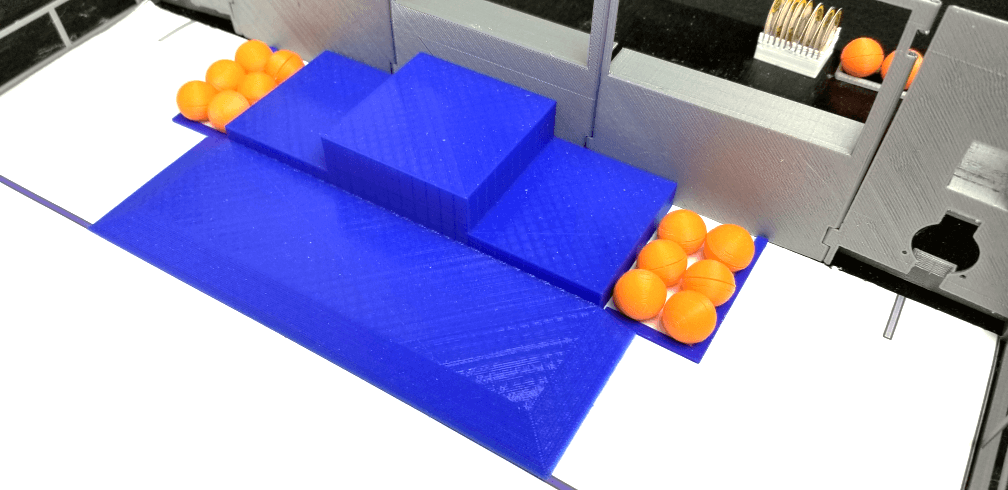

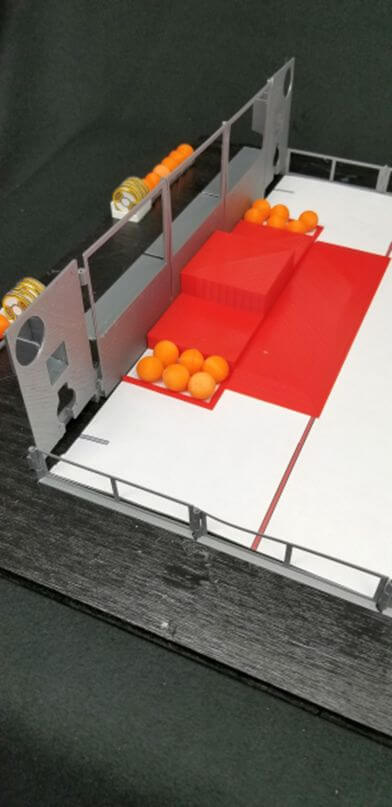

Place Habitat on surface and move Depots into place and add 6 Cargo:

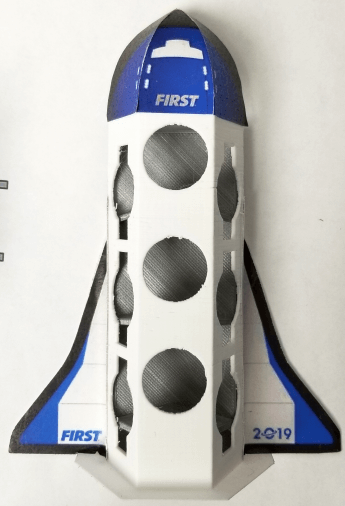

Rocket Assembly

Print the following items:

Qty Item

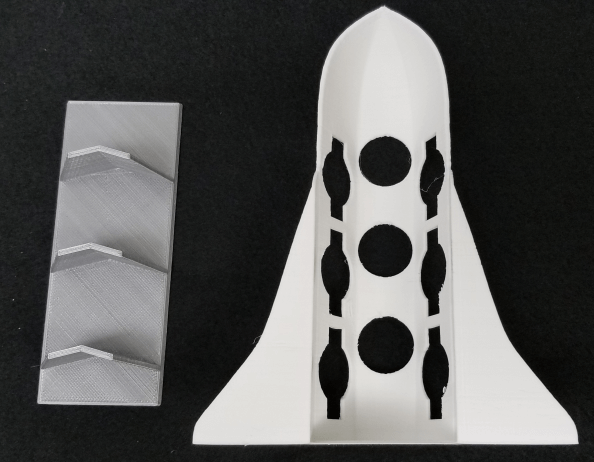

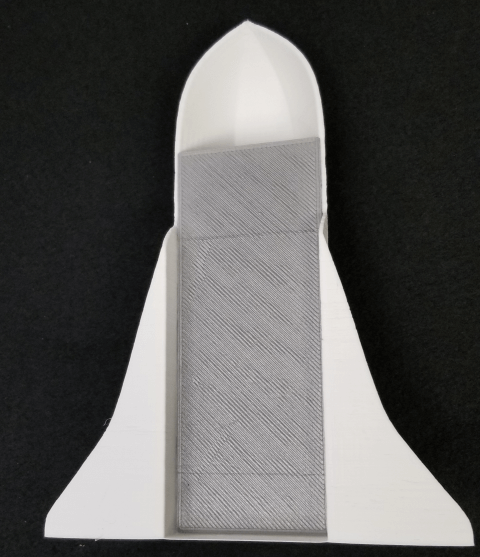

4 White Rockets

4 Silver Rocket Inserts 1 Blue Decals Decals 1 Red Rocket Decals

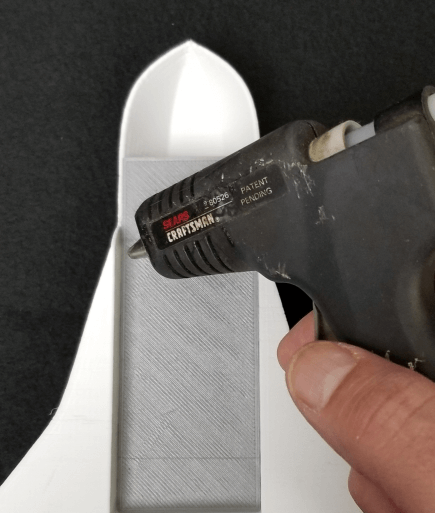

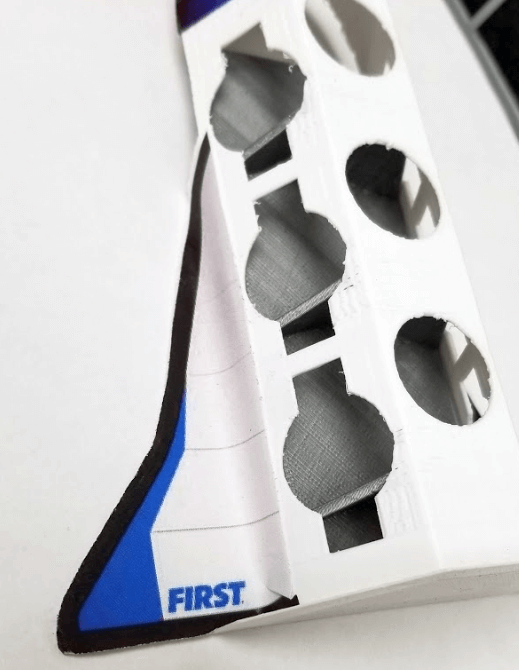

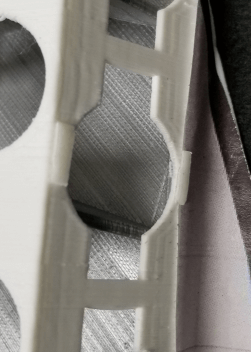

Hot glue rocket insert into place:

Apply Decals

Notice that Wing decal wraps around corner:

Add ”hook and loop” – We use 3M Command Strips cut into little strips:

Attach to Rocket Bays – Hatch panel can now be “hung” on rocket:

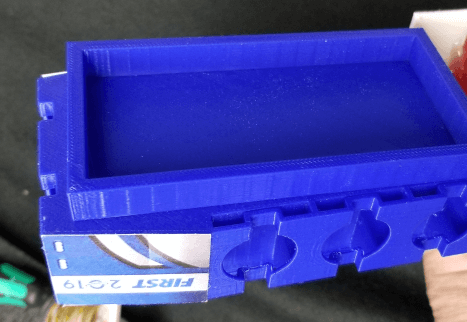

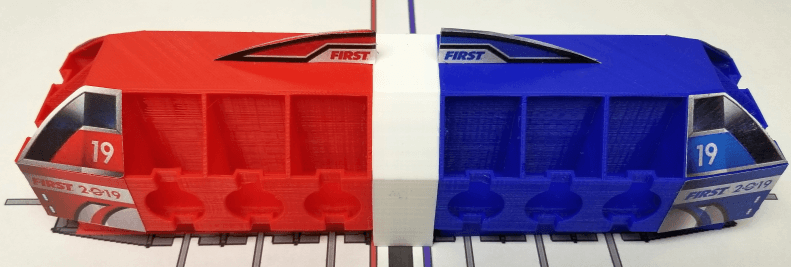

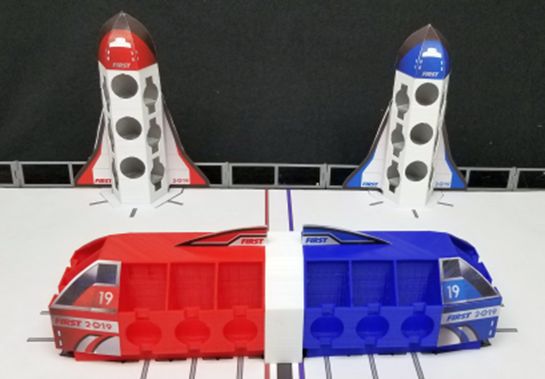

Cargo Ships:

Print the following items:

Qty Item

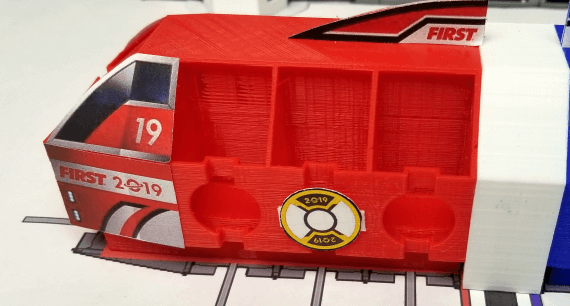

1 RED Cargo Ship

1 RED Cargo Ship Base

1 BLUE Cargo Ship

1 BLUE Cargo Ship Base

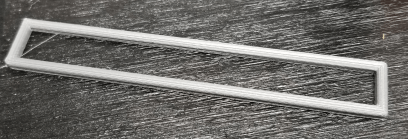

1 Cargo Ship Spacer

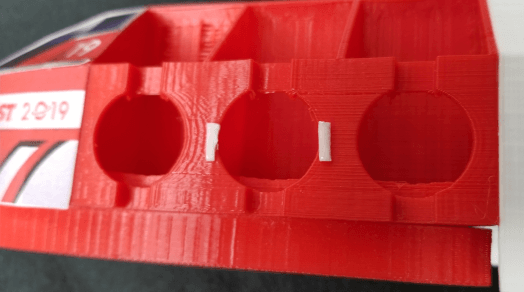

Glue Cargo Ship Bases to Cargo Ships (We use Super Glue):

Glue Cargo Ships together with white spacer in between (we use super glue) and apply decals:

Add “hook and loop” using

little strips of the 3M Command strip:

Add Hatch Panels:

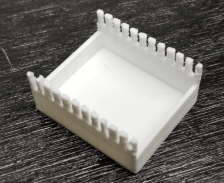

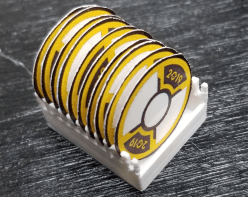

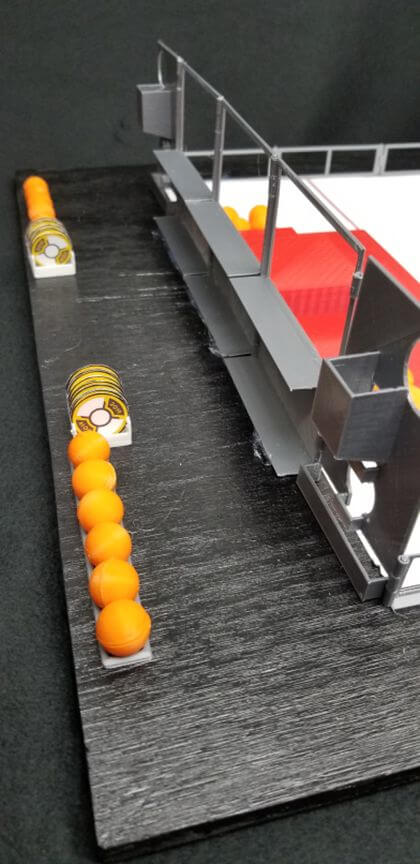

Game Element Racks

Just print them and load them up.

Hatch Panel

The Hatch Panels are too thin to 3D print, so we just printed them on heavy weight card stock paper which happens to be almost exactly the correct thickness (.25mm). These are cut by hand, but we also cut some using an inexpensive laser engraver. The nice thing about the laser is we could easily cut the inner circle:

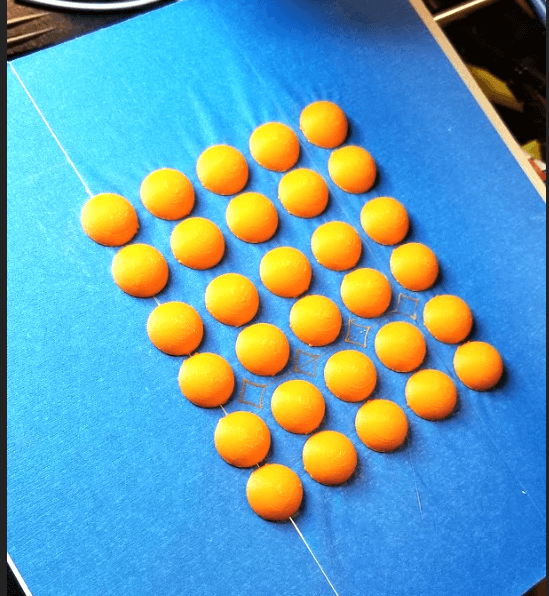

Cargo

Just print them and glue them together. A small dab of super glue works great.

We usually print about 15 (30 halves) at a time:

Enjoy!

Please let us know what you think and if you can show us a better way to do this!

You can reach us by e-mail:

educationalcontacts@automationdirect.com

Or on Chief Delphi:

Rick Folea: user: rfolea

Chip McDaniel user: only1chip

Additional Photos:

RED Cargo Ship

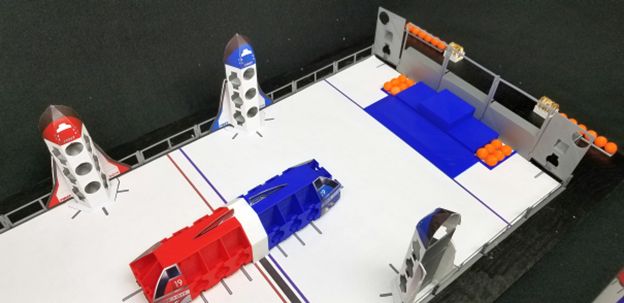

Center Field

Blue Field

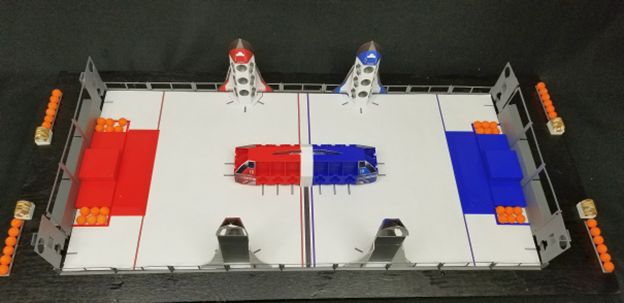

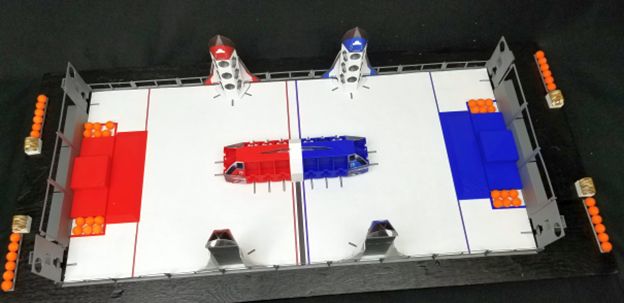

Full Field Top Down

Full Field

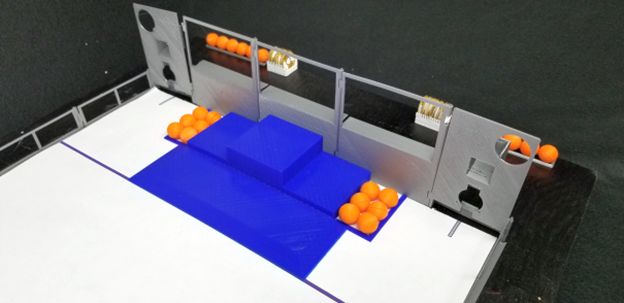

Habitat Blue

Habitat RED

Game Elements

Rocket RED

To read more articles from AutomationDirect, click here.