AutomationDirect has the Ethernet devices and installation media needed to future-proof factory and machine networking installations.

Consumer- and commercial-grade Ethernet networking has been common since the 1980s, and it has evolved significantly over the decades. Yet, Ethernet for industrial applications generally lagged behind commercial installations. In an Industrial Ethernet Book July/August 2023 article titled Advancing Industrial Ethernet Creates Choices for Networking, Bill Dehner at AutomationDirect covers some more recent advancements that are improving Ethernet for all types of industrial applications.

Networking Evolution

The earliest industrial networks used RS232/422/485 serial communications for point-to-point and small-count multi-drop communications among PLCs, HMIs, VFDs, and other industrial devices. This provided reasonable deterministic performance, useful installation distances, and a high degree of robustness for industrial environments.

As users adopted high-speed and cost-effective Ethernet throughout their business environments, they naturally wanted these same benefits in their automation systems to interconnect field devices, controllers, on-site computing, and cloud-based resources.

Industrializing Ethernet

Commercial off-the-shelf (COTS) Ethernet was not well suited for industrial installations, and early versions did not provide the determinism needed for critical applications. However, many developments have elevated Ethernet to today’s preferred industrial networking technology:

- Ruggedized installation media, such as shielded and flexible cables, with factory- and field-wired connectors—both RJ45 and M12 quick disconnect (QD) style—rated for harsh environments.

- High-speed industrial devices operating at 10/100 Mbps, and now up to 10 Gbps, capable of operating at extreme temperatures, powered by common industrial 24VDC or vehicle 12VDC while supporting PoE and PoE+ to conveniently power field devices.

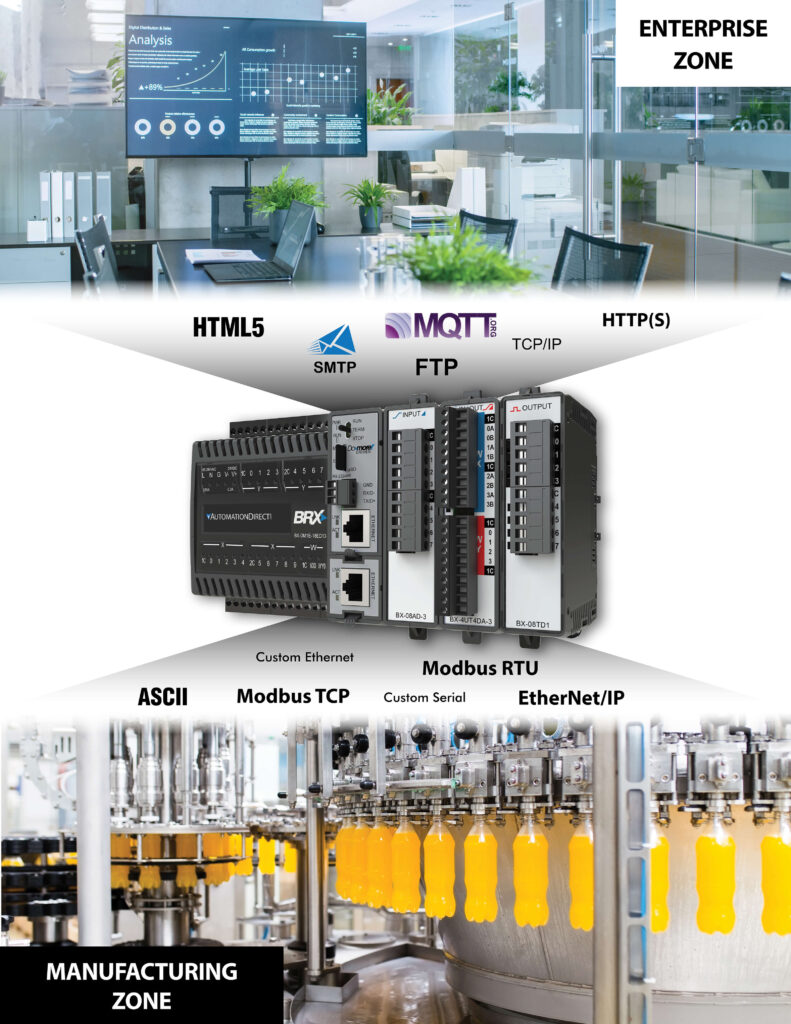

- A wide range of operational technology (OT) protocols, such as EtherNet/IP, Modbus TCP, PROFINET, EtherCAT, and others, along with information technology (IT) protocols like OPC UA and MQTT, which incorporate contextualized data exchange and cybersecurity provisions.

An Industrial Ethernet Future

Ethernet installations continue to provide new advantages. A fieldbus called IO-Link—specified by IEC 61131-9—provides cost-effective communications and power connectivity for many types of industrial field devices. Ethernet media enables IO-Link to connect seamlessly and simultaneously with PLC controllers and cloud computing assets.

Another exciting advancement is Ethernet-APL, which is a two-wire media format built upon the IEEE802.3cg standard. This is particularly useful for industrial installations because trunks can reach up to 1,000m with drops of 200m, and the simple wiring provides 10 Mbps communications combined with power.

There will always be cases where it makes technical and/or commercial sense for designers to specify the minimum viable installation media and networking devices. However, product availability and small cost premiums often mean the best approach to future-proofing is to select higher-performing Ethernet installation media and devices, especially with regards to communication speeds and industrial ratings.

Check out the complete range of AutomationDirect Ethernet switches, media converters, gateways, cables & connectors, and more to help end users, OEMs, and systems integrators establish reliable and cost-effective data exchange among industrial control and automation devices.