For the past nine years, the Navy has sponsored an Opportunity Forum for their Phase II SBIR (Small Business Innovative Research) contractors. The purpose is to publicize these government funded developments thereby helping viable business products to evolve beyond Navy needs. Successes triply benefit the small business, the Navy, and the American economy, and obviously are well appreciated by the Congress.

NASA SBIR companies have been added the last two years and the Navy also includes related Office of Naval Research (ONR) projects to be shown with the exhibits. In all, about 200 booths exhibited military wares and, in a seminar format, contractors described their products and outlined market plans.

Some 1,500 visitors attended the 8-10 June Forum at Crystal City, VA. Along with contractor and Naval project personnel, attendees were invited from major defense contractors and other large and hi-tech corporations as well as business persons such as national accounting firms, venture capitalists, and consultants.

Navy Commands and Major Programs

Most Navy originated SBIR contracts are for support products for major weapons systems such as carriers, other surface ships, submarines, and aircraft. The new F-35 Joint Strike Fighter program is a primary interest to many contractors and John W hite, Director of Engineering for the F-35s, was a luncheon speaker. The first three F-35s have been built at Lockheed-Martin in Ft. Worth. Expectations are that more than 4,000 F-35s will be produced over the coming decade. Three versions are now planned; an Air Force Fighter; A Navy Carrier Fighter; and a Marine Corps VTOL version.

Two ship configurations built by General Dynamics and Lockheed-Martin are in sea trials competing for the planned 55-Ship Littoral Fleet. These coastal assault vessels reflect advanced concepts in flexibility and modularity. Small basic crews of about 40 officers and men will operate the ships while trained teams will be assigned to handle selected weapons and/or special equipment packages. Like cargo containers, special equipment units can be rapidly and easily installed and replaced. Besides weapons systems, special units may support unmanned aerial, surface or undersea vehicles.

Two ship configurations built by General Dynamics and Lockheed-Martin are in sea trials competing for the planned 55-Ship Littoral Fleet. These coastal assault vessels reflect advanced concepts in flexibility and modularity. Small basic crews of about 40 officers and men will operate the ships while trained teams will be assigned to handle selected weapons and/or special equipment packages. Like cargo containers, special equipment units can be rapidly and easily installed and replaced. Besides weapons systems, special units may support unmanned aerial, surface or undersea vehicles.

The Navy Research Lab (NRL) with an overall $2.16 billion budget administers more advanced and special purpose SBIR projects. The NRL currently has projects underway with 637 small businesses and 1,035 universities. Two “developments to watch” are an electromagnetic hypersonic gun (part of an all-electric ship) and a Free Electron Laser weapon.

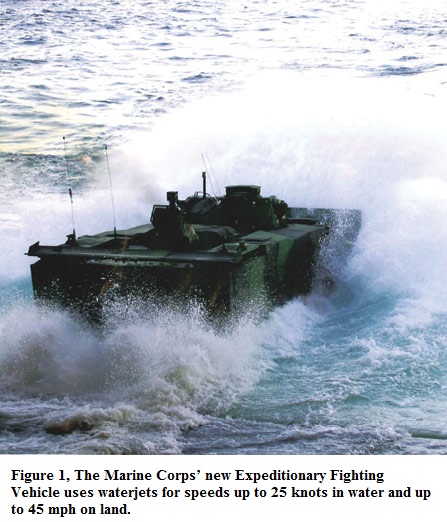

Land combat equipment developments are largely under the Marine Corps. Now well along in the testing phase is the EFV, the Marines’ amphibious Expeditionary Fighting Vehicle shown in Figure 1. The EFV uses a three-man crew to transport 17 combat loaded Marines. About two dozen SBIR projects contributed to the EFV; from bilge water handling to door seals to special high strength alloys.

Brief descriptions of five SBIR products follow. Selections were based on their potentials for possible dual use in industrial and/or commercial applications along with the likely interests of Automation Notebook readers.

Rotating Machinery; Lubricants & Fluids Monitoring

Navy preventative maintenance programs for rotating machinery continue to advance. Impact Technologies, LLC (Rochester, NY) described a system designed for the forthcoming joint strike fighter engines. Wireless sensors are networked to measure temperatures, pressures, vibrations, corrosion, and fluid qualities. System features include real time alarms, long term wear and performance trending, and suggested maintenance actions. Systems can be customized for other weapons systems and equipment such as: other aircraft, surface ship turbines, diesel engines, large cranes, and compressors.

A key innovative development is the fluid quality sensor (see Fig. 2), a patented Impact Technologies product.Fluid dielectric properties respond differently to various applied frequencies and thereby can provide real time fluid health data. The sensor generates a range of frequencies to measure a broadband spectra of AC electrochemical impedances, somewhat similar to optical spectroscopy (photo). Oils, hydraulic fluids, gear box oils, transmission fluids, and machine tool lubricants can be monitored. Contact for more information is Ryan Brewer at 585-424-1990 x 127 or e-mail ryan.brewer@impact-tek.com.

Blade-Mounted Sensors

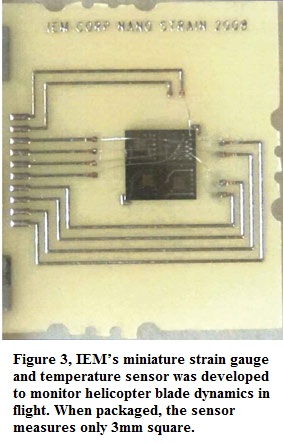

Another rotating machinery monitoring system was described at the ’08 Forum by International Electronic Machines (IEM). Along with a wireless sensor network and monitoring software, IEM has miniaturized and ruggedized wireless 2-D strain gauges with integrated temperature sensors (see Fig. 3) for mounting on helicopter rotor blades. Individual sensors are 3 mm square and consume about a milliWatt of power.

Nearby wireless nodes (1”x ½” x ½”) can handle multi-sensor channels and a special protocol enables data transfer rates about 30 times those of ZigBee networks. Data acquisition capabilities can be applied with other sensors and on all types of equipment, with either moving or stationary parts. Low power requirements encourage the use of harvested power. Contact is Ryk Spoor at 518-449-5504 x 25; e-mail rspoor@iem.net.

Mission Critical Communicating

VoxTec International provided an impressive demonstration of its Phraselator P2 hand-held machine-based language translation units shown in Figure 4. Applying commonly used phrases, some 8,000 units are currently in use, many in Iraq and Afghanistan. Languages and dialects are scroll selected from the 3.5-inch touchscreen. Once selected, the user simply speaks an English phrase such as Park your car over there or Point to the location on this map. At the touch of a key, the message is spoken in the selected language while simultaneously printed in that language on the screen.

Over 40 languages and dialects are now supported, each utilizing 1,000 or more phrases selected as most appropriate for the application. Phrase pools are developed for specific situations such as combat intelligence, insurgency control, civilian and/or medical liaisons, responding to natural disasters, and/or specific skill areas such as pipeline installations or road construction.

Over 40 languages and dialects are now supported, each utilizing 1,000 or more phrases selected as most appropriate for the application. Phrase pools are developed for specific situations such as combat intelligence, insurgency control, civilian and/or medical liaisons, responding to natural disasters, and/or specific skill areas such as pipeline installations or road construction.

No special user enunciation or speech training is needed; translation accuracies are running over 90 %. The unit draws 6 watts; four AA rechargeable batteries provide 10-12 hours of service, and single unit prices begin at less than $2,000. Newer versions will include two-way translations and long term foreign voice storage capability. Contact is VoxTec President John Hall at 410-626-1110 x 225; e-mail john.hall@voxtec.com.

Compact Portable Heat Pump

Underwater work and working durations of SCUBA divers in cold water are seriously compromised due to rapid chilling in waters which can be as low as 30o F at ocean depths. Under a NAVSEA contract, Rini Technologies has developed a compact and efficient heat pump which extracts heat from the sea water and circulates a 95o F sealed water working fluid for diver warming. A previously developed SCUBA wet suit and gloves have integrated heating tubes for delivering warmed water to divers’ torsos and extremities.

The heat pump is in a sealed cylindrical housing 3”dia. x 10.5” long, weighing 4 lbs. The pump is battery powered with the battery unit being a slightly larger cylindrical unit weighing 5.7 pounds and providing 125 watts for 2.6 hrs of operation between recharges. The unit uses standard 134A refrigerant and the heat pump mode provides a heating coefficient of performance (COP) of nearly 3 when extracting heat from 40o F seawater. The cylinders mount alongside the breathing tank and the system’s 10-pound total weight is insignificant in diving operations.

Some work has been done with the unit in the cooling mode to provide cooling for helicopter pilots flying in hot environments. CEO Dr. Dan Rini can be contacted at 407-359-7138 x 103 or by e-mail at dan@rinitech.com.

Communication in Extreme Noise Environments

Carrier catapult crews have developed hand signals to communicate in the ultra-high noise environments (upwards of 150 dB) of carrier jet launches. Such signaling requires line-of-sight vision and has serious information limits. For future launch support, Adaptive Technologies working with Aegisound combined custom designed ear plugs and headset cuffs with digital noise-canceling circuitry and microphone to allow near-normal short range RF communications in high noise levels associated with carrier launches.

The system has been demonstrated within tracked vehicles and inside large compressor stations. Reportedly, hearing losses among military veterans cost the VA over $1 billion per year. Contact is Aegisound’s Jeff Hammel at 540-449-9856; e-mail jeff@aegisound.com.

Developments from military-driven technologies continue to infiltrate the wider industrial and

commercial markets. For more information on the Navy SBIR Program, visitwww.navysbir.com.

By Ken Ball

Originally Published: Sept. 1, 2009