There are safety related features in practically every device we use, industrial and non-industrial. Electrical devices and appliances have housings that protect consumers from electrical hazards. Motorized devices have housings intended to prevent any possible injury to users from dangerous moving parts and/or electrical components. Industrial facilities have many safety features including safety signs that warn workers of possible hazards, and all equipment and machinery have pushbuttons, switches, shields and other devices intended to prevent any possible injury to workers and operators.

Safety must always be the primary concern for industrial facilities, from protecting employees from accidental injuries to protecting equipment from serious damage, which in turn may result in costly downtime and repairs. Industrial processes and operations use high speed machinery, automated systems, equipment that moves heavy parts or handle hazardous materials. In the U.S., the government created the Occupational Safety and Health Administration (OSHA), which enforces standards and provides training, outreach and assistance to ensure that workers have a safe and healthful workplace. In addition, most manufacturing facilities implement industry safety standards and safety procedures developed for their own site-specific safety needs, which might be unique. Sometimes these safety procedures are established after the facility experiences a serious accident that caused injury or fatality to a workforce member. This is why it is extremely important to follow OSHA and industry safety standards. But in addition to these, each facility should also take the initiative to perform internal audits to analyze and determine any possible area in the facility where a potential hazard may be identified and take the proper steps to eliminate the risk. With all the technology available today, there is no acceptable excuse to not implement a safe environment for your employees.

A Few Examples of Industrial Safety Devices and Components

Even though we would like to list every possible safety device and component, there is just no room to do that in a simple blog. However, the following is a brief look at some designed for industrial use. We encourage you to take a look at your systems and see how any of these may help make your facility safer. You may also visit our website for further research on these and other devices that may not be included here.

Cable-Pull Safety Switches: Cable-pull safety rope switches allow operators to initiate an E-stop from any point along the installed cable length, providing robust protection for exposed conveyors or machines, or wherever equipment cannot be protected by guards. Read more

Disconnect Switches: Provide a means for ensuring a circuit is completely de-energized and a location. For locking during service, maintaining maximum safety for personnel. Read more

Enclosures: Enclosures house and protect electrical components and wiring in a wide variety of environments, where NEMA rating standards define the degree and type of protection. Read more

Fuses and Fuse Holders: Fuses provide overcurrent or overload protection in an electrical circuit to prevent damage to the load or power source and provide protection from a chance of electric shock to a worker. Read more

Fuses and Fuse Holders: Fuses provide overcurrent or overload protection in an electrical circuit to prevent damage to the load or power source and provide protection from a chance of electric shock to a worker. Read more

Interlock Safety Switches: Two examples of these safety switches are; the tongue interlock and the hinge interlock safety switches.

- The tongue interlock safety switches fit sliding, hinged or lift-off machine guards and provide a tamper-resistant actuator mechanism, with positively operated switching contacts for operation confirmation. Read more

- The hinge interlock switches provide positively operated switching contacts and a tamper-resistant actuator mechanism for hinging machine guards. Read more

Non-contact Safety Switches: The four types are; the non-contact RFID coded, coded magnetic, magnetic, and magnetic locking RFID safety switches. All these safety switches can monitor opening/closing of machine guards, doors, or other machinery. Read more

Circuit Breakers: Protect feeder, branch and control circuits from overload current, which in turn protects equipment and workforce. Read more

Intrinsically Safe Isolators: Provide intrinsic and galvanic separation between the control system and the field device. Read more

Two-Hand Safety Controls: Require simultaneous actuation by both hands to initiate and maintain hazardous machine functions. Read more

Safety Laser Scanners: An innovative way to protect a mobile unit such as an AGV or even a static hazardous area like a work cell. Read more

Safety Light Curtains: These devices use an array of photoelectric beams to sense intrusion into a plane of detection, offering protection where a process may require open and frequent access. Read more

Safety Limit Switches: Provide positively operated switching contacts to verify the position of machine elements or other moving parts for safety related purposes. Read more

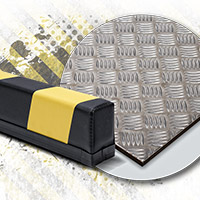

Safety Mats and Edges: Safety mats and edges are used to protect people and machinery from harm. Mats detect the presence of personnel on horizontal surfaces (usually the floor), while edges can be used on any surface, usually near possible crushing or shearing points. Both mats and edges are wired to specialized safety relays for fail-safe triggering of the intended safety function. Read more

Safety Relay Modules: Uses monitoring logic as well as overvoltage and short-circuit protection, in combination with redundant relays, to provide a high level of fail-safe operation. Read more

Stack Lights: Stack lights offer modular stackable components that provide illuminated and audible status indication for machines, systems and processes. Read more

Surge Protective Devices: Designed to protect electrical equipment or installations from voltage spikes by blocking unwanted voltages above a safe threshold. Typical applications include AC power distribution, drive line drive input and control panel protection. Read more

Surge Protective Devices: Designed to protect electrical equipment or installations from voltage spikes by blocking unwanted voltages above a safe threshold. Typical applications include AC power distribution, drive line drive input and control panel protection. Read more

Trapped Key Interlock Switches: Trapped key systems use a series of mechanical locks and keys to control the access of gates or doors to running equipment or machines, ensuring safe access. Keys are trapped and released in a sequential order. Read more

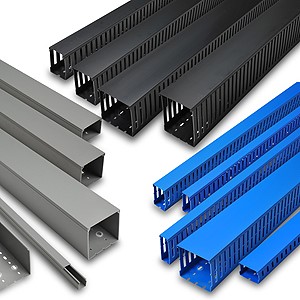

Wire Ducts and Tubing: Available in a variety of rigid or flexible designs and colors, wire ducts and tubing keep wiring protected and organized while protecting workers when they access an enclosure or panel interior. Read more

Safety Bumpers: are typically used to detect presence of heavy equipment in applications involving transport vehicles, industrial trucks, high-shelf warehouses, production lines, or mobile systems. These vibration-resistant bumpers provide reliable detection in harsh conditions.

These are just a few examples of industrial devices that help provide a safe work environment. Don’t let cost stand in the way of making a machine or process as safe as possible. You need to be in compliance with national and international standards, but you don’t need to overpay to get reliability and high performance for maximum machine safety.

AutomationDirect offers a superb line of machine safety devices with prices that let you do even more to protect what’s important. Choose from our vast selection of certified offerings of brand name machine safety components to meet your protection needs.

Click here to view additional articles on safety topics.