AutomationDirect is proud to have a network of system integrators covering a wide variety of industrial control processes across the country. KCC Software, in Huntsville, Alabama, provides services in all areas of the United States and in several countries around the world. Tim Roberts, Integrator Coordinator for AutomationDirect, recently talked with KCC Software owner and founder, Scott Martin, to learn more of what he and his company have to offer.

How did you get started in your Controls/Engineering career?

I moved from programming Space Station automation to a mechanical systems department of my employer. This introduced me to the world of control systems in the semiconductor industry. I entered as a programmer and quickly fell in love with the bigger picture of systems integration with programming being my “specialty”.

How long have you been doing Systems Integration work?

I started this work in 1986 and have been fully immersed ever since – 26+ years now. Now, at least 25% of systems I develop and deliver involve replacing 1980s and 1990s microprocessor systems with PLCs.

What was the most interesting application in which you have used PLCs from AutomationDirect?

For IBM’s Watson Research Center, I developed the Silane distribution system. Silane is a volatile gas that ignites when exposed to atmosphere. Storing it under significant pressure and distributing it through the center comprises a true challenge.

Everything has to be controlled and monitored continuously throughout the facility in order to avoid catastrophic possibilities.

The solution included a series of DirectLOGIC DL 205 PLCs networked and in constant communication to share the task of safe gas containment and delivery. In addition to networked PLCs, the project also used C-more HMI panels throughout the facility and in research labs, as well as a PC-based Think & Do system for site-wide status monitoring and alarm and event historical logging.

What made that project unique/challenging?

The gas delivery covers hundreds of feet of monitored tubing with potentially fast-acting pressure and temperature changes that have to be controlled for the safety of all concerned. Due to the high pressures and flammable nature of the gas involved, the constant communication between PLCs for shared control was challenging – not only for what had to happen normally, but also for what had to happen when anything unexpected occurred.

What is a favorite aspect of integration to you?

Variety – every project is different. Each industry has its own challenges. Each task of the system requires unique skills. From designing to programming to assembly to commissioning – the variety keeps each day exciting.

What was the most difficult programming (or engineering) project you ever tackled using PLCs from AutomationDirect?

What was the most difficult programming (or engineering) project you ever tackled using PLCs from AutomationDirect?

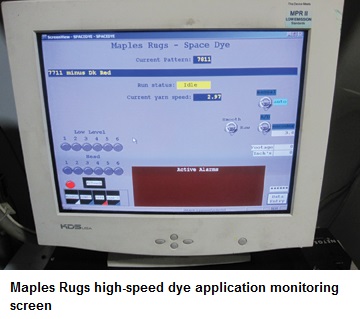

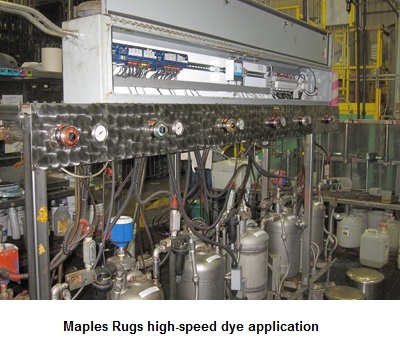

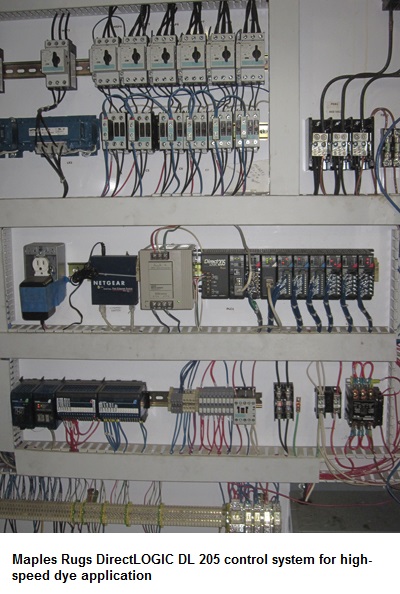

For Maples Rugs, I developed a DirectLOGIC DL 205 controlled highspeed dye application process that sprayed six different colors of dye into yarn as it sped through the machine at 1200 feet per minute.

The dye had to be sprayed in 0.0125 tolerances to apply the pattern desired. The spray controls continually monitor the yarn tension and speed and adjust to fluctuations in real-time.

In addition to the dye application control system, I developed a desktop pattern design application allowing the client’s design department to create thrug designs. An interpretation of this pattern was then converted and downloaded into the control system to apply the design exactly as desired. The obstacles included getting the pattern concept into the DL 205 PLC and adjusting in real-time as the speeds and tensions of the yarn strands changed.

How did you overcome the obstacles?

The obstacle of getting a concept to a pattern and then into the PLC as a series of actions was accomplished through .Net programming. This ability to program at multiple levels (PC, PLC) is one of the advantages offered by KCC Software. The timing issues related to adjusting the spray application based on real-time tension and speed fluctuations was accomplished through a central timing algorithm that drove the dye application. Both major obstacles were overcome through welldesigned algorithms.

Tell about a ‘breakthrough’ moment for you in your approach to control system applications.

Prior to 2000, all of my programming was in C and in both embedded and PC-based applications. Around 2001, I saw a PLCDirect catalog with a new DL06 PLC on the cover.

I immediately saw how combining PC-based programming with the PLC integration would help me provide better and more robust solutions for my clients. The low-cost, yet powerful and capable, entry into the PLC/integration business has served my clients and my business very well, Without AutomationDirect, this likely never would have happened.

To learn more about what KCC Software has to offer, visit: www.kccsoftware.com.

Disclaimer: AutomationDirect does not guarantee the products described in this article are suitable for your particular application, nor do we assume any responsibility for your product/system design, installation, or operation.

Originally Posted: Dec. 12, 2012