Specialty equipment and mechanical contractors, in this case a cryogenic systems solutions provider, can extend their project delivery capability by partnering with experienced automation systems integrators.

By Kyle Lamb, Quantum Automation

Extreme cold temperature and freezing techniques are essential for many industries, but some of the most demanding applications are found in the scientific, research, pharmaceutical, and medical sectors. These entities often require the use of liquid nitrogen (LN2) freezers for exceptionally low-temperature and long-term storage of biological samples. All freezing technologies require some degree of maintenance, and while LN2 systems generally do not demand immense user interaction, their processes do require careful storage, distribution, and replenishment of bulk liquid nitrogen.

Traditional LN2 installations are often largely manual affairs or use very simplistic controls. While this type of basic functionality is workable, more advanced designs provide many end-user benefits. For example, automated supply tank switching, effective alarm delivery (facilitating prompt problem mitigation), and the ability to achieve better control performance all serve to streamline operations and provide value.

Planning for a Cryogenic Upgrade

As a specialty supplier of cryogenic systems solutions, CryoPacific is well-versed in the design, manufacturing, and installation of LN2 storage, distribution, and associated equipment, for completely new projects as well as upgrades/updates. When a client requested an upgrade to their existing LN2-based storage freezer system, it was determined that the work also required adding more sophisticated monitoring and control capabilities (Figure 1).

Figure 1: A large healthcare provider operates numerous LN2 tanks supplying cryogenic sample storage equipment, and required hardware, instrumentation, and automation upgrades to obtain better performance.

The four existing supply tanks already included basic instrumentation used during LN2 deliveries, but this client was due for operational visibility and automation upgrades. For instance, the current system did not intuitively inform staff as supply tanks emptied, requiring diligent user attention, and the client wanted to improve overall performance by adding automated tank switching. Considering the degree of functionality specified, CryoPacific chose to partner with an industrial automation systems integrator (SI) with full-time experience creating control panels and applying industrial-grade digital technologies.

Because CryoPacific was already familiar with AutomationDirect products and their positive performance on previous projects, the team used the supplier’s “SIDirect” website to investigate member SIs with demonstrated product and application expertise. With a convenient map interface, and filters for various product technologies and service skills, it was easy to identify well-qualified and conveniently located SI candidates, and to select the best fit for this engagement.

Quantum Automation, based in Anaheim CA for over 30 years, began as an industrial product distributor and expanded over the years to provide UL508a control panel fabrication, contract manufacturing, and control systems integration services. With experience in renewable energy, petrochemical, food, pharmaceutical, and other related industries, the Quantum team had the skillset needed to support the CryoPacific project.

Creating a Cool Design

CryoPacific engineering began by developing a mechanical and piping design, along with flow diagrams, to support the client’s needs. The work quickly transitioned into defining how to automate the system and provide a comprehensive user interface. Monitoring tank status and levels required specifying and installing new pressure transmitters and differential pressure/level instruments, which were specified as ProSense devices sourced from AutomationDirect. In addition, new automated valves needed to be controlled by the system as well.

Handling nitrogen, especially in relatively enclosed spaces, introduces additional safety concerns. Nitrogen is an odorless gas that can displace oxygen in the air, which in turn can cause unconsciousness or even death by asphyxiation, without any prior warning signs. For this reason, installing and integrating oxygen monitoring and alarming systems in these types of environments are paramount for protecting personnel. In the event that a low oxygen level is detected—potentially due to a nitrogen leak—or if any personnel initiate an emergency stop (E-stop), the LN2 control system must take action to halt nitrogen distribution, alert operators, and perhaps perform other mitigative tasks. At this site, there was already an existing building management system (BMS) with oxygen detection sensors to integrate with the new automation.

To accomplish this project, the Quantum team specified a compact programmable logic controller (PLC) with a graphical touchscreen human-machine interface (HMI). The PLC needed to handle about 50 discrete input, discrete output, and analog input points in total, but the selected controller was capable of operating many more if needed for future expansion (Figure 2).

Figure 2: The AutomationDirect Productivity1000 stackable micro PLC, and a 10” C-more touch screen HMI are compact and industrial-rated, making it easy to design and fabricate an operator-friendly control panel.

The implementation team also needed to consider that the end user required BACnet digital communication protocol connectivity so that the new LN2 automation system could transmit alarms to the existing BMS system, which would provide additional visibility for users. Therefore, a gateway was required to convert the BACnet MS/TP (master-slave, token-passing) serial connectivity to an Ethernet Modbus TCP format suitable for the PLC to interact with.

With these requirements established, the team proceeded to design and then fabricate a compact control panel to house the PLC, HMI, and gateway. The control panel was installed just outside of the freezer area, so operators could safely interact with it even in the event of a nitrogen leak within.

Improved Usability and Oversight

Once the automation platform was established, the team focused on creating PLC logic and HMI configurations. Before this project, LN2 distribution largely relied on operators manually monitoring physical gauges and manipulating hand-operated valves. It was essential for the new HMI display to be easily usable by all types of personnel (with appropriate access credentials).

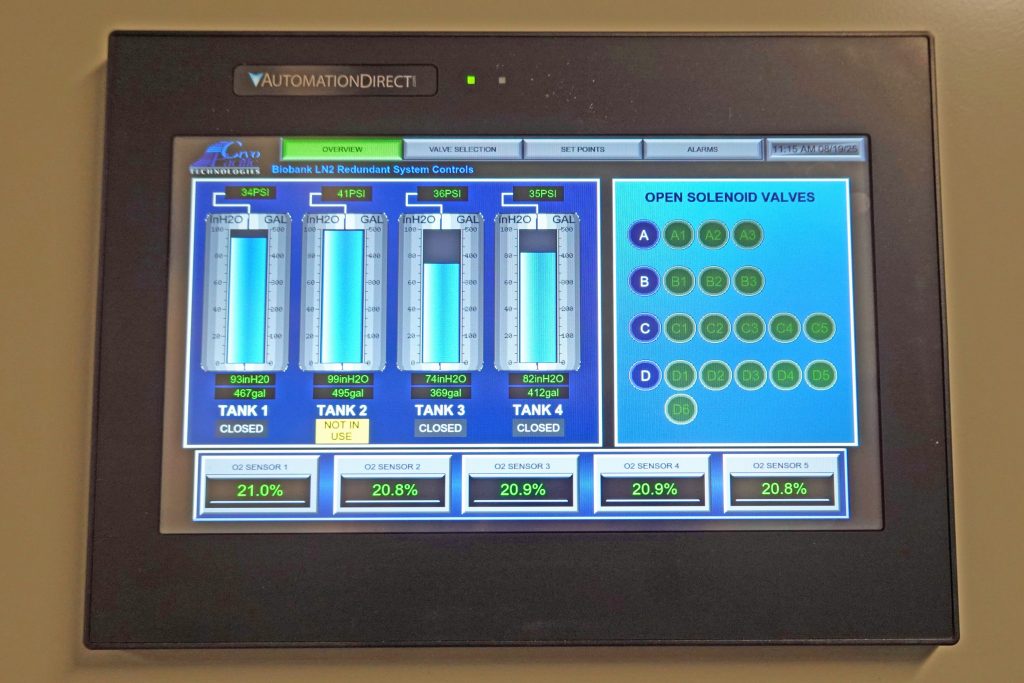

Some basic functional requirements included (Figure 3):

● Clear display of LN2 tank status (pressure, level in inches of H2O, volume in gallons, tank active or out-of-service)

● Indication of valve and refrigeration/freezing bank status

● Ability to select valves (which tank is primary for supplying LN2, and which tank is secondary if the primary goes empty)

● Configuration display for entering setpoints

● Readouts for O2 sensors

● Display of alarms, with audible/visual indicators located around the area

Figure 3: Although the AutomationDirect HMI monitoring and PLC control system was far more sophisticated and capable than the manual approach formerly in place, the visualization and user-accessed features were easily usable by all types of personnel.

Both SIs and end users appreciate that the software for this PLC and HMI platform is freely available. The software emphasizes ease-of-use in conjunction with superb functionality, and the manufacturer website provides extensive technical materials, training videos, and support options. In addition, the PLC software also has an integrated simulation mode, so the control logic and associated HMI graphics could largely be pre-tested on the benchtop prior to field deployment and commissioning. The ability to preview operation with the end user provided a high level of confidence in the configuration, along with reduced risk and field costs.

The Cold Facts of Success

This cryogenic project is representative of a multitude of similar undertakings worldwide, where designers apply incremental upgrades and new technologies to update existing systems and improve performance. The contractors and original equipment manufacturers (OEMs) who perform this type of work need access to proven automation products, and oftentimes rely on SIs specializing in the implementation of these technologies. As a result of this project’s success, CryoPacific and Quantum anticipate future work together.

Quantum wrapped up this project by producing a helpful user manual, and performing on-site training for the end user. Even though this automated system was a step change up from the legacy LN2 management approach, the client easily adjusted to the new capabilities and immediately took advantage of improved alarm notifications, visibility, and automatic valve control to improve operational performance.

All figures courtesy of Quantum Automation

Author Bio

Kyle Lamb is the engineering manager at Quantum Automation, having joined the team over seven years prior as an intern while attending college. From designing control panels and schematics, to performing PLC programming, HMI configuration, and full system integrations, Kyle focuses on delivering reliable and efficient solutions for clients. Kyle holds a bachelor’s degree in mechanical engineering at California State University, Fullerton.